Prima Packaging Tape for Anti-Slip Bathroom and Office Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Anti-slip Tape

1. Structure: Surface: choice anti-slip sand, rubber anti-slip fiber, sand-free special anti-slip material; Middle Layer: PET, PP, PVC and aluminum, etc. Base glue: ready-to-use waterproof strong viscose. Base paper: white/leather silicone paper.

2. Appearance of Colors: Black, gray, red, orange, blue, between yellow and black, red and white, transparent, white, reflective, night light-emitting, etc. printing a variety of beautiful picture and patterns according with customer requirements.

3. Types: 1) super anti-slip 2) cozy anti-slip 3) general anti-slip 4) easy-to-clean

Application of Anti-slip Tape

1) Equipment: skateboard, scooter, running machine, exercise machine, machine tool, footplate of printing machine, passages on buses or stairways.

2) Locations: Kindergarten, school, swimming pool, nursing home, bus station, subway station, train station, pier, hotel, club house, kitchen, washing room, playground, health and recreation facilities, entrance of elevator, pedestrian slope, shopping mall, working area and deck, etc.

3) Also applicable to tourist car, ship, tow truck, truck, aircraft, hanging ladder, large- or small-sized power equipment.

Advantage of Anti-slip Tape

1.Anti-slip tape, superb tack and adhesion to surface, Strong grip that is ensured because of an excellent adhesive backing.

2. Peak performance even under extreme conditions of pressure and temperature, which can stick to all types of surfaces.

3. Consistent quality

4. on time delivery

5. Effective and timely communication

6. Competitive price

Packing of Anti-slip Tape

individually wrapped, shrink, carton.

6rolls/shrink, about 36~100rolls/carton(according to different specifications)

carton size : any carton size as your request

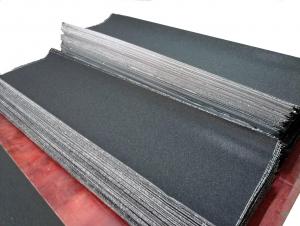

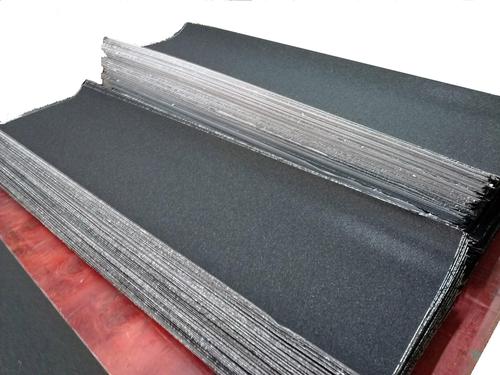

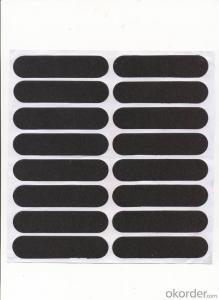

Pictures of Anti-slip Tape

Specification of Anti-slip Tape

| Material | PVC, PP, PE |

| Adhesive Side | Single Sided. |

| Adhesive | Acrylic, Water based acrylic adhesive. |

| Acrylic | Water based acrylic adhesive. |

| Color | Transparent clear/yellowish /tan brown/blue/red/ green |

| Normal thickness | 45mic, 46mic, 48mic,50mic, 52mic, 55mic, 60mic, 65mic, 70mic etc |

| Color | black, white, clear, blue, and print as customer’s requirment. |

| Mesh | 40# 60# 80# 100# 150# |

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

1. What is the range of your products?

So far, we manufacture various kinds of double sided adhesive tape, masking tape, kraft tape and BOPP packing tape. To better meet your needs, we can also source other adhesive tapes for you if it is appropriate to do so.

2. What's the lead time for delivery?

We ensure you a prompt delivery of the goods. We do not stock any of the goods. The production cycle time of 1*20FCL is 2-3 weeks.

3. How many carriers does your double sided adhesive tapes have?

There are many carriers that our double sided adhesive tapes based on, which are tissue, PET, BOPP, PE foam, EVA foam.

4.Can you accept the cooperation way of OEM?

Upon receipt of formal authorization, we can accept OEM processing.

5.What are the international commodity codes for these products?

HS Code: 48231900.

6.Are you offering only jumbos rolls or slit rolls as well?

We offer Jumbos, logs, and slit rolls. All different sizes are available.

- Q: Does packaging tape come in different materials for specific applications?

- Different materials are used for specific applications when it comes to packaging tape. One type that is commonly used is polypropylene, which is a versatile material suitable for general-purpose packaging. It is strong, durable, and resistant to moisture and temperature changes, making it suitable for a wide range of uses. However, for more specialized purposes, different materials may be necessary. For example, if you need extra security or tamper-evident features, you might consider using security tape. This type of tape is often made of thicker and stronger materials like polyester or reinforced paper. It is designed to leave a visible mark or message when tampered with. In certain situations, packaging tape specifically designed for extreme temperature conditions may be required. For instance, if you are shipping goods that will be exposed to freezing temperatures, you will need to use freezer-grade packaging tape that remains adhesive and effective in low temperatures. Similarly, some applications may call for tape that can adhere to challenging surfaces like corrugated cardboard or recycled materials. In such cases, you can choose packaging tape with aggressive adhesive properties or one that is specifically formulated for adhesion on difficult surfaces. Moreover, there are eco-friendly options available for those who prioritize sustainability. Environmentally friendly packaging tapes are often made from renewable or recycled materials and use non-toxic adhesives. In conclusion, the choice of packaging tape material depends on the specific requirements of the application, such as security, temperature resistance, surface compatibility, or environmental concerns. It is essential to select the appropriate tape to ensure the safe and secure packaging of your items.

- Q: Can packaging tape be used for sealing plastic wrap?

- No, packaging tape is not typically used for sealing plastic wrap. Packaging tape is designed to adhere to cardboard and other surfaces, providing a secure seal for packages. On the other hand, plastic wrap is a thin, transparent film used to cover and protect food or other items. It is typically sealed by pressing the edges together or using a specialized plastic wrap cutter. While packaging tape may provide a temporary seal, it is not designed for use with plastic wrap and may not provide a secure or long-lasting seal. It is recommended to use the appropriate method for sealing plastic wrap, as specified by the manufacturer.

- Q: Can packaging tape be used for sealing metal boxes?

- Indeed, metal boxes can be sealed using packaging tape. Specifically engineered to create a secure and long-lasting seal on different surfaces, such as metal, packaging tape possesses a powerful adhesive that effectively adheres to metal, guaranteeing that the box stays sealed throughout storage or transportation. Nevertheless, it is crucial to select a packaging tape appropriate for demanding tasks, capable of enduring the weight and pressure that the metal box may experience. Furthermore, it is advised to cleanse the metal surface prior to applying the tape to ensure optimal adhesion.

- Q: How do I prevent packaging tape from tearing during removal?

- To prevent packaging tape from tearing during removal, you can try gently heating the tape with a hairdryer to soften the adhesive. This will make it easier to peel off without tearing. Additionally, you can use a knife or a razor blade to carefully cut along the edges of the tape before peeling it off.

- Q: How does packaging tape perform on non-porous surfaces?

- Packaging tape is designed to adhere to a wide range of surfaces, including non-porous ones. Non-porous surfaces, such as glass, metal, plastic, or sealed wood, offer a smooth and impermeable surface, which can sometimes make it challenging for adhesives to stick effectively. However, packaging tapes are engineered with strong adhesive properties that allow them to perform efficiently even on non-porous surfaces. When applied to a non-porous surface, packaging tape forms a strong bond due to its high tackiness and cohesive strength. The adhesive on the tape is formulated to have excellent adhesion properties, ensuring a reliable seal. It firmly sticks to the surface, creating a secure bond that is resistant to peeling or lifting. Additionally, packaging tapes are often designed with special features like acrylic or hot melt adhesives, which enhance their performance on non-porous surfaces. Acrylic adhesive tapes are known for their excellent initial tack, quick adhesion, and long-term durability. They can withstand temperature changes, humidity, and UV exposure, making them suitable for various environments. Hot melt adhesive tapes offer superior bonding strength and are ideal for heavy-duty applications, ensuring a strong hold on non-porous surfaces. Moreover, packaging tapes are typically made from durable materials like polypropylene or polyester, which are resistant to tearing or stretching. This further enhances their performance on non-porous surfaces, as they can withstand the rigors of shipping and handling without compromising their adhesive properties. In summary, packaging tape is specifically designed to perform well on non-porous surfaces. Its strong adhesive properties, special adhesive formulations, and durable materials allow it to create a reliable seal on glass, metal, plastic, or sealed wood. Whether for packaging, shipping, or general use, packaging tape is a reliable choice for securing items on non-porous surfaces.

- Q: How many tapes do you need to make a tape? How do you calculate a mother roll and how many tapes do you make?To make a tape, you need a roll,1, how to calculate a mother roll, how many tapes do?2, now the mother rolls have what specifications?3. How much is the mother volume now?4, how do you calculate the profit of a roll of tape?

- 1 how much roll tape does a square of a mother roll divide by the square of a single adhesive tape. Of course, this includes lossExample: the square of a volume is 4800, and the square of a tape of a specification of 60*45.7 is about 2.74, then the volume of the tape isEqual to 1751 rolls, because there is a loss of about 1700

- Q: Can packaging tape be used for sealing packages with perishable food items?

- No, packaging tape should not be used for sealing packages with perishable food items. Perishable food items require proper packaging materials that can provide airtight and moisture-resistant seals to maintain their freshness and prevent contamination. Packaging tape is not designed for this purpose and may not be able to provide the necessary level of protection. It is recommended to use specialized food-grade packaging materials like plastic wrap, vacuum-sealed bags, or resealable containers to ensure the safety and quality of perishable food items during transportation.

- Q: Can packaging tape be used for sealing plumbing or pipe fittings?

- No, packaging tape should not be used for sealing plumbing or pipe fittings. Packaging tape is not designed to withstand the pressure and conditions that plumbing systems require. It is not suitable for use with water or other liquids, and it may not provide a secure and long-lasting seal. Plumbing and pipe fittings require specific types of sealing materials, such as Teflon tape, pipe dope, or thread sealants, which are specifically designed for plumbing applications. Using packaging tape for sealing plumbing or pipe fittings can result in leaks, water damage, and potentially costly repairs. It is always recommended to use the proper sealing materials and techniques recommended by plumbing professionals.

- Q: How do I prevent packaging tape from tearing during application?

- To prevent packaging tape from tearing during application, there are several steps you can take: 1. Choose the right type of packaging tape: Make sure you are using a high-quality packaging tape that is designed for heavy-duty applications. Look for tapes that are specifically labeled as tear-resistant or reinforced. 2. Prepare the surface: Before applying the tape, ensure that the surface is clean, dry, and free from dust or debris. A dirty or uneven surface can cause the tape to tear easily. 3. Use proper technique: When applying the tape, hold the roll at a slight angle to the surface rather than perpendicular. Applying it at an angle will reduce the amount of friction between the tape and the surface, minimizing the chances of tearing. 4. Apply gentle pressure: Apply the tape smoothly and evenly, using gentle pressure. Avoid pulling or tugging too hard, as it can strain the tape and increase the risk of tearing. 5. Avoid extreme temperatures: Extreme temperatures can affect the adhesive properties of the tape and make it more prone to tearing. If possible, store the tape in a controlled environment and avoid using it in extremely hot or cold conditions. 6. Consider using a tape dispenser: Using a tape dispenser can help you apply the tape more smoothly and evenly, reducing the chances of tearing. It also provides better control and minimizes the strain on the tape. 7. Cut the tape cleanly: When cutting the tape, use a sharp blade or scissors to ensure a clean cut. A jagged or uneven cut can weaken the tape and make it more likely to tear. By following these tips, you can significantly reduce the chances of packaging tape tearing during application and ensure a secure and reliable seal for your packages.

- Q: Is packaging tape safe to use on stainless steel?

- Yes, packaging tape is safe to use on stainless steel. Packaging tape is typically made from materials that are not corrosive and will not damage the surface of stainless steel. However, it is always a good idea to test the tape on a small, inconspicuous area of the stainless steel before applying it to the entire surface, especially if the tape will be left on for an extended period of time. Additionally, removing the tape gently and slowly can help prevent any potential damage or residue on the stainless steel.

Send your message to us

Prima Packaging Tape for Anti-Slip Bathroom and Office Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords