Stained Brown Anti-Slip Film Faced Plywood Formwork

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

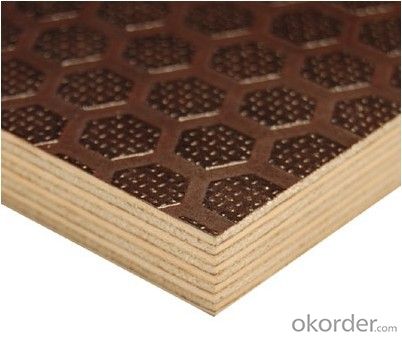

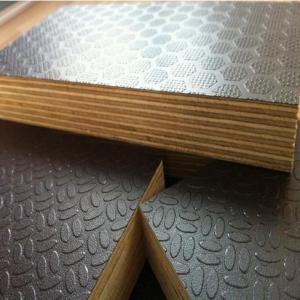

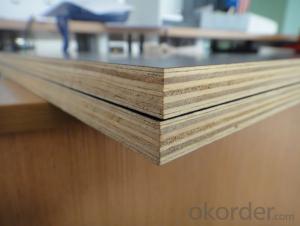

Anti-slip brown film faced plywood

Specifications of Anti-slip Film Faced Plywood

1) Size: 1220×2440mm, 1250×2500mm,1500×3000mm,1525×3500mm, or as request

2) Thickness: 4-100mm

3) Glue: MR, Melamine,WBP Core: Poplar, Birch, Pine, Hardwood,etc

4) Surface: Imported Brown/Black Film; Chinese Brwon/Black Film

5) Anti-slip Pattern: Square, Hexa grip, etc

6) Special Treatment: Bevel, Tongue & Groove,Punch, etc

7) Moisture Content: 8-14%

8) Application: Concrete forming, Platform, Cassette Systems and Trailer Flooring, etc.

Packaging & Delivery

1.Packaging Detail: loosing package,pallets package,all can according to customers'requirements

2.Delivery Detail: delivery within 10 days after get the deposit

Advantage of Anti-slip Film Faced Plywood

1.No wapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

- Q: Plywood in the material defects?

- discoloration discoloration Where the normal color of wood changes called color, can be divided into two kinds of chemical discoloration and fungal discoloration.

- Q: What does plywood mean and its synthesis?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides.

- Q: What is the best way to fix multi-layer plywood?

- Commonly used plywood type plywood, penta and so on. Plywood can improve timber utilization and is a major way to save wood. T

- Q: What harm does the plywood factory work?

- occupational chronic benzene poisoning refers to the workers in the professional activities Long-term exposure to benzene vapor caused by hematopoietic system damage as the main manifestation of systemic disease.

- Q: What are the processing defects of plywood?

- Warping warPing is generally a regular deformation, part or all of the surface of the plywood is curved.

- Q: What is the use of plywood for construction?

- Plywood is the direction of the logs along the ring to cut into large sheets of single board, after drying, after coating by the adjacent veneer layer grain direction perpendicular to the principle of the billet, glued from the plate.

- Q: What are the defects of the plywood?

- unsound section unsound knots The decaying part of a section of a child does not exceed 1/3 of the knot.

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

- Q: Decorative veneer veneer plywood features

- Decorative veneer veneer plywood is one of the most commonly used materials for interior decoration

- Q: The basic principle of plywood

- are symmetrical. In the same plywood, you can use a single tree and veneer thickness, you can also use different tree species and thickness of the veneer

Send your message to us

Stained Brown Anti-Slip Film Faced Plywood Formwork

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords