Anodized Aluminum Coil for Sale - Roofing Ceiling Decorative Aluminium Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Roofing Ceiling Decorative Aluminium Coated Coil

lProduct Information

Alloy | Thickness (mm) | Width (mm) | Temper | DC or CC |

1050,1060, 1070,1100,1235 | 0.2-3.0 | 20-1800 | O, H12, H22, H14, H24, H16, H26, H18 | DC, CC |

3.0-12.0 | 900-1900 | H111, H112 | DC | |

3003,3004,3105,3005 | 0.2-3.0 | 20-1800 | O, H12, H22, H14, H24, H16, H26, H18 | DC, CC |

3.0-12.0 | 900-1900 | H111, H112 | DC | |

5052,5083,5754,5005 | 0.2-3.0 | 20-1800 | O, H12, H22, H14, H24, H16, H26, H18 | DC |

3.0-12.0 | 900-1900 | H111,H112 | DC | |

8011 | 0.0065-0.2 | 20-1500 | O, H22 | DC,CC |

Interior Diameter | 75mm,150mm etc. or as your request | |||

Outer Diameter | 300mm, 505mm etc. or as your request | |||

lPackaging & Delivery Details

Packaging: Standard seaworthy packing

Delivery: About 25 days after received your advance

lCompany Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building

material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

CNBM has been involved in aluminium products for about a decade. With advanced technology and equipment, our products have been sold to the worldwide including America, Europe, as well as South Asia, etc.

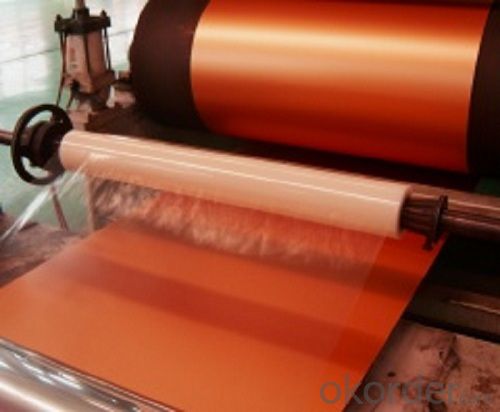

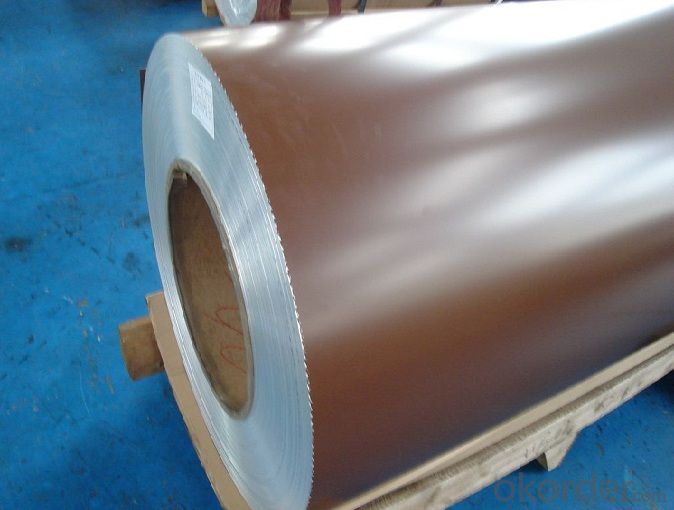

lProduct Images

lCertificates

lFAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

- Q: Can aluminum coils be used in the production of automotive body panels?

- Yes, aluminum coils can be used in the production of automotive body panels. Aluminum is a lightweight and durable material that offers excellent corrosion resistance, making it ideal for automotive applications. The use of aluminum coils helps to reduce the weight of the vehicle, resulting in improved fuel efficiency and overall performance.

- Q: Are aluminum coils suitable for lightweight panel applications?

- Indeed, lightweight panel applications can benefit from the use of aluminum coils. Renowned for their lightweight and corrosion-resistant properties, aluminum coils prove to be an exceptional option for these applications. With ease, aluminum coils can be molded and fashioned into panels of various sizes and thicknesses, showcasing their remarkable versatility. Moreover, the high strength-to-weight ratio exhibited by aluminum facilitates the production of robust and enduring lightweight panels. These panels find utility across a range of industries, including automotive, aerospace, construction, and transportation, where the reduction of weight is paramount. All in all, the lightweight nature, corrosion resistance, versatility, and strength of aluminum coils render them a fitting choice for lightweight panel applications.

- Q: How are aluminum coils protected during shipping?

- Aluminum coils are protected during shipping through various methods to ensure their safety and prevent any damage. One common method is the use of protective packaging materials such as bubble wrap, foam, or corrugated cardboard. These materials are used to wrap the coils and create a cushioning effect, absorbing any impact or vibration that may occur during transportation. In addition to protective packaging materials, aluminum coils are often placed in sturdy shipping containers or crates. These containers are designed to provide extra security and stability during transit, minimizing the risk of the coils being jostled or bumped. Moreover, in some cases, aluminum coils are secured with strapping or banding to keep them in place and prevent shifting or movement during transportation. This helps to maintain the integrity of the coils and minimize the risk of damage caused by rubbing against other objects. Furthermore, shipping companies may also use air-bag systems or dunnage bags to fill any empty spaces within the shipping container. This further reduces movement and provides an additional layer of protection for the coils. Overall, the protection of aluminum coils during shipping involves a combination of packaging materials, secure containers, and preventive measures to ensure their safe arrival at their destination.

- Q: Are there any limitations to using aluminum coils?

- Using aluminum coils comes with several limitations. Firstly, their cost is higher compared to other materials like copper, which can be a constraint for those with budget constraints. Secondly, aluminum coils have lower thermal conductivity than copper coils. This means they are less efficient at transferring heat, resulting in decreased performance in some applications. In addition, aluminum is more prone to corrosion and oxidation than other materials. This limitation is particularly relevant in highly corrosive environments, like coastal areas or industrial settings. Moreover, aluminum coils are generally unsuitable for high-pressure applications. They are more likely to experience leaks or failures under high pressure, which restricts their use in certain HVAC systems or refrigeration units. Lastly, aluminum coils are less malleable than copper coils, making them more challenging to handle during installation or repair. This can lead to increased labor costs or potential damage to the coils during handling. Overall, although aluminum coils have advantages like being lightweight and environmentally friendly, their limitations must be carefully considered based on the specific application and requirements.

- Q: The choice between Vinyl and Aluminum? By Mastercraft Exteriors

- Vinyl. Aluminum dents, and the paint can be scratched off. Vinyl pops back, and the color goes all the way through.

- Q: What are the potential health hazards associated with the use of aluminum coils?

- <p>There are concerns about the health risks associated with using aluminum coils, particularly in cooking. Aluminum can leach into food when heated, and excessive intake may lead to cognitive impairment and neurological issues. However, the risk is generally considered low with normal usage. It's important to follow proper cooking practices and use utensils that are not reactive with aluminum to minimize exposure. For those with concerns, alternatives like stainless steel or cast iron can be used to reduce potential health risks.</p>

- Q: Are aluminum coils suitable for pharmaceutical vial caps?

- Pharmaceutical vial caps can indeed be made from aluminum coils. When it comes to pharmaceutical packaging, aluminum is highly favored thanks to its exceptional barrier properties. These properties effectively shield the vials' contents from moisture, oxygen, and other harmful substances. Aluminum coils can be easily molded into caps of various sizes and shapes, accommodating different types of vials. Another advantage is that aluminum is a lightweight material, which makes transportation and handling hassle-free. Additionally, aluminum is resistant to corrosion, ensuring that the vial caps remain intact throughout storage and usage. In summary, due to their barrier properties, versatility, and durability, aluminum coils are a suitable option for pharmaceutical vial caps.

- Q: Can aluminum coils be used in the manufacturing of cans and containers?

- Yes, aluminum coils are commonly used in the manufacturing of cans and containers. Aluminum is lightweight, durable, and resistant to corrosion, making it an ideal material for packaging food and beverages. The coils are typically processed and shaped into desired can or container forms before being used in the manufacturing process.

- Q: Are aluminum coils suitable for high-temperature roofing applications?

- No, aluminum coils are not suitable for high-temperature roofing applications.

- Q: Can aluminum coils be used for electrical applications?

- Yes, aluminum coils can be used for electrical applications. Aluminum is a widely used material in the electrical industry due to its excellent conductivity, lightweight properties, and corrosion resistance. Aluminum coils are commonly used in various electrical applications such as transformers, motors, generators, and coils for inductors and solenoids. They offer advantages such as high thermal conductivity and low eddy current losses, making them efficient in transferring and distributing electrical power. Additionally, aluminum coils are cost-effective compared to copper coils, making them a preferred choice for many electrical applications. However, it is important to note that aluminum has a lower electrical conductivity compared to copper, so the coil design and dimensions may need to be adjusted accordingly to ensure optimal performance.

Send your message to us

Anodized Aluminum Coil for Sale - Roofing Ceiling Decorative Aluminium Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords