American Standard Smooth Geomembrana in HDPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description:

1.used in landfill caps

2. base liner applications under roads, railways,

3.as well as within various other containment structures such as dams, canals, ponds, rivers and lakes

Our product was proved as good physical and mechanic performance,

oil and salt, alkali and corrosion resistance, high and low temperature resistance, non-toxicity, long operational life, good waterproof, drainage, anti-seepage and damp proof effects.

2.Product Characteristic:

1) Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial, hospital solid waste, etc.) .

2) Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart, slope protection, etc.).

4) Landscape (man-made lake, river, reservoir, golf courses reservoirs of the substrate, slope protection, green lawn of the waterproof moisture, etc.).

3.Product Specifications:

1.thickness : 0.1---3.0mm,

2.Length: 50 m -100 m ; width: 1 m -8 m ( according to customer needs )

3.Elongation at break:700%

4.Material: HDPE.

5.Color: Black or as you required

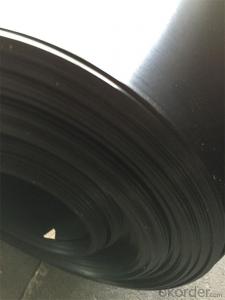

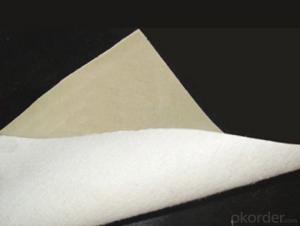

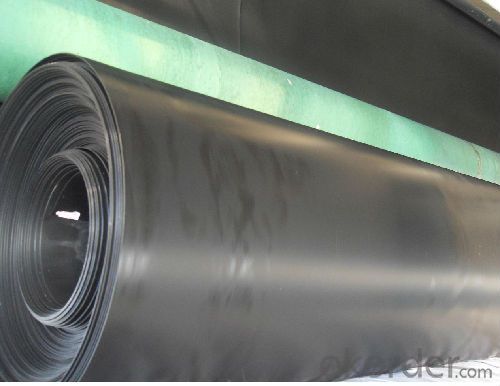

4.Reference Picture

- Q: What materials are used to make HDPE geomembrane and HDPE anti-seepage film?

- They are all amde from HDPE material.

- Q: Painting film thickness standard

- there is no specific criteria. no matter what kind of painting you are sparying, you can not brush until the treament of coating surface, otherwise there is no way to guarantee quality. brushing by hand for 2 - 3 times. Simple brushing needs at least two sides, if advanced brush need to be able to see the film thickness, it would need the N side. brushing until you are satisfied, pay attention to the quality of spraying, and pay attention to environmental protection

- Q: How are geomembranes tested for durability?

- Geomembranes are tested for durability through a combination of laboratory and field tests. In the lab, various mechanical tests, such as tensile strength and tear resistance, are conducted to evaluate their strength and resistance to external forces. Additionally, accelerated aging tests, like weathering and chemical exposure, are performed to simulate long-term environmental conditions. Field tests involve installing geomembranes in real-world applications and monitoring their performance over time, including their ability to withstand stress, deformation, and degradation. These comprehensive testing methods ensure that geomembranes are durable and can withstand challenging conditions in different environments.

- Q: Where does the smooth surface of seepage-proof geomembrane face?

- Negative direction that can increase frictions.

- Q: What are the advantages of the Cherry keyboard film and other key keyboards?

- The characteristics of the different axes of the cherry keyboard are as follows: Green axis trigger key distance is 2.4mm, and the pressure is 60g, and click life is 20 million times. It has obvious paragraphs sense; tea shaft trigger key distance is 2.0mm, and the pressure is 60g, and click life is 20 million times. It has unconspicuous sense of paragraph; red axis trigger key distance is 2.0mm, and the pressure is 60g, and click life is 20 million times. It has no paragraph sense and straightens up and down; black shaft trigger key distance is 1.5mm, and the pressure is 80g, and click life is 50 million times. It has no paragraph sense and straightens up and down.

- Q: Are geomembranes resistant to animal waste?

- Yes, geomembranes are generally resistant to animal waste. They are designed to withstand various environmental conditions, including exposure to animal waste, and are commonly used in agricultural, farming, and waste management applications to prevent leakage and contamination.

- Q: What if there is water during construction of geomembrane?

- The main role of geomembrane on the road is water insulation, the part higher than the underground water level is isolated by geomembrane, and then backfill and grind, preventing the water through soil capillarity from soaking roadbed filler.

- Q: Composite geomembrane (350g / 1.0mmHDPE / 350g) What does it mean?

- the specification of composite geo-membrane Geomembrane cloth membrane, also known as two cloths film one film, 0.01-mm high-density geomembrane composite geomembrane on (350g / 1.0mmHDPE & # 47, the thickness of the intermediate impermeable film quality is 1: Both sides of the geotextile (geotextile) mass per unit area is 350 g

- Q: JS waterproof, SBS, SBC, PVC, geomembrane, what are the disadvantages of these waterproof materials?

- Geomembrane is not suitable to be in complex pipeline project and constructions. SBS adopts hot melting construction; SBSJS waterproof coating cannot be constructed in below freezing and rainy days, PVC, and the film will need some time to dry, which is not suitable for waterproofing roof. The construction of SBC is complex.

- Q: Can geomembranes be used for erosion control in rivers and lakes?

- Yes, geomembranes can be used for erosion control in rivers and lakes. They are impermeable barriers made from synthetic materials that can effectively prevent soil erosion by acting as a protective layer. Geomembranes can be installed along the banks of rivers and lakes to prevent water from eroding the soil and causing further damage. They are a reliable and widely used solution for erosion control in water bodies.

Send your message to us

American Standard Smooth Geomembrana in HDPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords