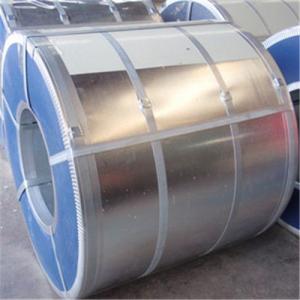

Aluminum Steel Coils for Ceiling, Building Material in Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | Standard seaworthy packing for long distance transportation |

| Delivery Detail: | in 25-30 days upon the receipt of original L/C or 30% deposit |

Product Description

Specifications

Material | 1, 2, 3, 5, 6, 7, 8 Series |

Temper | O, F, H14, H34, H32, H112, T4, T6 |

Surface treatment | Mill Finish, Anodized, Electroplates, Powder Coated, Wooden Finish, Polished |

Color | Plain, Silver, Black, Red, Blue, or as required |

Length | 1000mm~6000mm, or as required |

Shape | Plain, bossed, or as per the drawings and samples |

Fabrication | Cutting, drilling, punching, bending, etc |

Tolerances | As per your requirements |

Package | inner plastic paper interleaving each piece profile, outer fixed by plywood; or customized. |

Payment terms | T/T or L/C at sight |

Price terms | FOB; CIF |

Delivery time | 15~20 days after order confirmation |

Certification | ISO 9001:2008; SGS |

Application | Decorations, Fence, Building, Aviation industry, Mechanical equipment |

Capacity | 5000 tons per month |

MOQ | 1 Metric ton

|

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

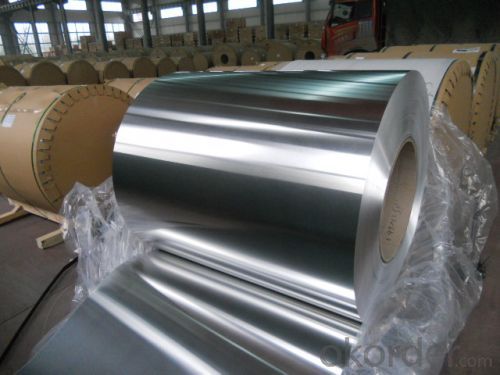

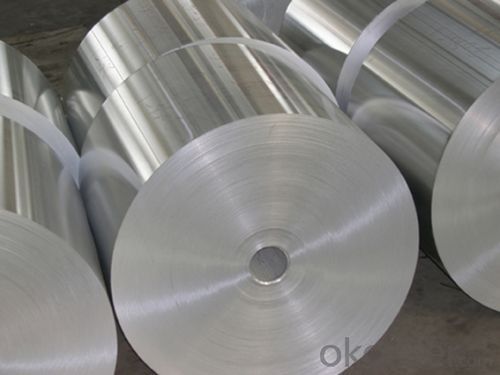

Photos

- Q: What will be the pros and cons of using each of these materials?One thing to keep in mind is that aluminum alloys are good conductors of electricity.

- get fiber glass,they will last a long time

- Q: This question asks for a comparison of various types of insulation materials, highlighting their unique characteristics and differences.

- <p>Different types of insulation materials vary in their properties such as thermal resistance (R-value), fire resistance, moisture resistance, and environmental impact. Fiberglass is a common, cost-effective option with good thermal resistance but can be irritating to the skin and respiratory system. Cellulose insulation is made from recycled paper and has good sound absorption but may be less fire resistant. Foam insulation like spray foam offers excellent insulation and air sealing but can be more expensive and harder to install. Mineral wool is fire-resistant and durable but may be less thermally efficient. Each type has its advantages and drawbacks, and the choice depends on factors like cost, environmental impact, and specific insulation needs.</p>

- Q: Can aluminum coils be used for electrical conductors?

- Indeed, aluminum coils are capable of serving as electrical conductors. Aluminum, being a metal with exceptional conductivity, finds frequent utilization in electrical contexts. With electrical conductivity ranking second only to copper, aluminum proves to be a fitting material for the conduction of electricity. In numerous electrical apparatuses and setups like transformers, motors, generators, and power transmission lines, aluminum coils are commonly employed.

- Q: How should aluminum coil be stored to maintain its quality and prevent damage?

- <p>The best way to store aluminum coil involves several key practices: Store the coil in a clean, dry, and well-ventilated area to prevent moisture and dirt accumulation. Ensure the storage area is free from corrosive substances and temperature fluctuations. Use pallets or racks to keep coils off the ground, and avoid stacking heavy items on top. Protect coils with plastic covers or wrapping to prevent dust and scratches. Organize coils by size, type, and grade for easy access and to prevent damage during handling. Regularly inspect stored coils for signs of damage or corrosion and rotate stock to minimize prolonged storage of any single coil.</p>

- Q: Are there any limitations or restrictions on the use of aluminum coils?

- Aluminum coils come with limitations and restrictions that need to be taken into account. Some of the key limitations are as follows: 1. Corrosion: Aluminum is prone to corrosion, especially when exposed to certain chemicals or environments. This means it may not be suitable for applications where it will encounter corrosive substances or highly corrosive environments. 2. Strength: Although aluminum is lightweight, it lacks the strength of metals like steel. This limits its use in applications requiring high strength or load-bearing capabilities. 3. Temperature sensitivity: Aluminum has a lower melting point compared to other metals, which can be a drawback in applications involving high temperatures. It may not be suitable for certain industrial or high-temperature environments. 4. Electrical conductivity: While aluminum has good electrical conductivity, it falls short of copper's conductivity. This can limit its use in applications requiring high electrical conductivity, such as electrical wiring or power transmission. 5. Cost: Aluminum can be more expensive than other metals, making it less favorable in cost-sensitive applications. In such cases, alternative materials may be preferred. 6. Formability: Compared to some other metals, shaping or forming aluminum coils can be challenging. This restricts their use in applications that demand complex shapes or tight tolerances. When selecting aluminum coils for a specific purpose, it is crucial to consider these limitations and restrictions. A careful evaluation of the particular requirements and constraints will help determine whether aluminum coils are suitable or if alternative materials should be considered.

- Q: What are the common surface defects found in aluminum coils?

- Some common surface defects found in aluminum coils include: 1. Scratches: These are visible lines or marks on the surface of the coil that can be caused during handling, transportation, or processing. Scratches can impact the appearance and functionality of the aluminum coil. 2. Dents: Dents are depressions or deformations on the surface of the coil. They can occur due to mishandling or impact during transportation or storage. Dents can affect the structural integrity and aesthetics of the aluminum coil. 3. Corrosion: Aluminum is susceptible to corrosion, especially in environments with high levels of moisture or exposure to chemicals. Corrosion can appear as pitting, discoloration, or roughness on the surface of the coil. It can weaken the coil and compromise its performance. 4. Streaking: Streaks are thin lines or bands that appear on the surface of the coil, often caused by uneven coating or surface contamination. Streaking can affect the visual appeal of the aluminum coil and may indicate a problem with the manufacturing process. 5. Oxide spots: Oxide spots are small, discolored areas on the surface of the aluminum coil, caused by the formation of aluminum oxide. These spots can occur due to oxidation during processing or storage. While they do not typically affect the performance of the coil, they can be aesthetically undesirable. 6. Oil stains: Oil stains are greasy or oily marks on the surface of the aluminum coil, often caused by improper cleaning or handling. These stains can affect the adhesion of coatings or paints and may require additional cleaning or treatment. 7. Roll marks: Roll marks are elongated depressions or raised lines on the surface of the coil, caused by the rolling process during manufacturing. While roll marks are generally unavoidable, excessive or severe roll marks can impact the appearance and quality of the aluminum coil. It is important to note that proper quality control measures, handling, and storage practices can help minimize or prevent these surface defects in aluminum coils.

- Q: Are aluminum coils suitable for interior decorative applications?

- Yes, aluminum coils are suitable for interior decorative applications. They are lightweight, durable, and can be easily shaped and colored to match various design requirements. Additionally, aluminum coils offer resistance to corrosion, making them suitable for long-term use in interior spaces.

- Q: How do aluminum coils compare to other metal coils like steel or copper?

- Aluminum coils have several distinct advantages compared to other metal coils like steel or copper. Firstly, aluminum is much lighter in weight, making it easier to handle and transport. Additionally, aluminum has excellent corrosion resistance, ensuring durability and longevity in various environments. Furthermore, aluminum coils have superior thermal conductivity, allowing for efficient heat transfer. Lastly, aluminum is more cost-effective compared to copper, while still providing reliable performance. Overall, aluminum coils offer a compelling combination of lightweight design, corrosion resistance, thermal conductivity, and cost-effectiveness when compared to steel or copper coils.

- Q: I was wandering, if your spear's shaft is made of aluminum, does that have any strength to it, i mean, say you had to block with the shaft, would a weapon break through like your basic sword or basic axe, i don't mean big heavy swords and axes, but like average ones, could it break through an aluminum shaft of a spear?

- From my understanding aluminum weapons are only for exhibitions and never for anything close to real, let alone impact. Aluminum can be a strong/durable metal, but in the end it can hardly hold up against wood like pine, let alone oak. There's also here-say about aluminum shattering. I don't really know what that's about, but I have heard a rumor that about some doing so, whatever the extend of shattering really means. I wouldn't bother with aluminum when there's very fine woods that can be used instead. Aluminum is also cheap and it's said you get what you pay for. Personally, I'd forget aluminum and go with a hard wood.

- Q: actually pollute more than the process of extracting it from earth and producing new aluminum?I saw a report about 5 years ago on this and was wondering if anyone else had info on this subject.

- I don't know the specifics, but I know it's not more than the extraction process. When aluminum is mined, it is in the form of bauxite ore. From this ore, only about half contains aluminum oxide. Then, from the mass of aluminum oxide (alumina), only about half of that will yield the pure aluminum we use for cans, airplanes, etc. So for every 2000 pounds that are mined, we only get about 500 pounds of aluminum. The process is extremely energy intensive and tears up the landscape where bauxite is mined. Transport adds to the pollution. Some of the biggest bauxite producers in the world are China, Russia, Canada, the United States, Australia, and Brazil, so overseas transport is frequently involved, especially in countries that use a lot of it. Furthermore, it is often shipped in bauxite or alumina form, when it is heavier to carry. Aluminum recycling, however, starts with the pure product and ends with the pure product, and the process is fairly quick. The aluminum can you recycle today will return to shelves within about 60 days. Furthermore, aluminum does not degrade in quality like some other materials so it can be reused indefinitely. The transport is also cut significantly, as recycled aluminum might only travel 100 miles or so to be refabricated.

Send your message to us

Aluminum Steel Coils for Ceiling, Building Material in Good Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords