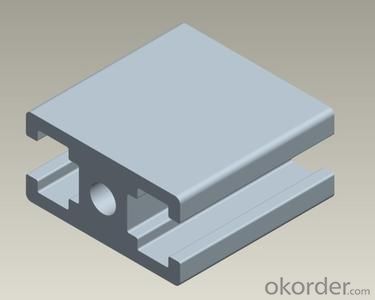

Aluminum Standard Industrial Aluminium Extrusion Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: What are the different surface engraving options for aluminum profiles?

- There are several surface engraving options available for aluminum profiles. Some of the most common methods include: 1. Laser engraving: This technique uses a high-powered laser to etch the desired design or text onto the surface of the aluminum profile. Laser engraving provides precise and clean results, making it ideal for intricate patterns and fine details. 2. Diamond drag engraving: Also known as diamond scratch engraving, this method uses a diamond-tipped tool to scratch the surface of the aluminum profile. It creates shallow grooves that can be used to create logos, serial numbers, or other simple designs. 3. Chemical etching: Chemical etching involves using a chemical solution to remove specific areas of the aluminum profile. This process is often used to create custom designs, patterns, or textures on the surface of the profile. 4. Mechanical engraving: Mechanical engraving utilizes a rotating cutting tool to engrave the aluminum profile. This method is commonly used for basic text or simple designs and can be done manually or with the help of a CNC machine. 5. Sandblasting: Sandblasting involves shooting a high-pressure stream of sand or other abrasive materials onto the surface of the aluminum profile. This process creates a textured surface and can be used to achieve a matte or frosted finish. Each of these surface engraving options offers unique benefits and can be chosen based on the desired outcome, complexity of the design, and budget considerations. It is important to consider factors such as durability, precision, and aesthetic appeal when selecting the most suitable engraving method for aluminum profiles.

- Q: The aluminum panel is the cart, ordinary nylon plate, the wheel is not conductive wheel, why use aluminum surface will be static, but not in the nylon plate, not easy to produce electrostatic in high resistance material?

- Electrostatic powder spraying on aluminum surface is not to prevent static electricity, it is to use the static electricity to spray the powder on the surface of the aluminum.

- Q: What are the various materials that can be combined with aluminum profiles in construction or manufacturing?

- <p>Aluminum profiles can be combined with a variety of materials to enhance their functionality and durability. Common materials include steel for added strength, plastics for lightweight components, and various types of glass for transparency and aesthetics. They can also be paired with rubber or silicone seals for weatherproofing, and wood for a warmer, more natural aesthetic. Additionally, aluminum profiles are often used with other metals such as copper or brass for electrical conductivity or corrosion resistance. The choice of material depends on the specific application, desired properties, and design requirements.</p>

- Q: This question asks for a list of various roofing systems that incorporate the use of aluminum profiles.

- <p>Aluminum profiles are used in several types of roofing systems for their durability, lightweight, and corrosion resistance. Some common types include: 1. Standing Seam Roofing: Known for its sleek, clean appearance and watertight properties. 2. Aluminum Shingle Roofing: Mimics the look of traditional shingles but with the benefits of aluminum. 3. Metal Tile Roofing: Offers the aesthetic of clay or slate tiles with the strength of aluminum. 4. Aluminum Panel Roofing: Consists of large panels that cover a broad area quickly and efficiently. 5. Aluminum Shake Roofing: Provides a rustic look similar to wooden shakes but with the longevity of aluminum. Each system has its own advantages and is chosen based on factors like design, cost, and environmental conditions.</p>

- Q: What are the top 20 Chinese architectural aluminum profiles?

- 7 、 Guangya Aluminum Industry Co., Ltd.8 、 Guangdong Xinhe Aluminium Industry Co., Ltd.9, Suzhou LOPSKING aluminum Limited by Share Ltd10, Fujian Minfa aluminium Limited by Share Ltd11, Shandong Huajian Aluminum Group Co. Ltd.12 、 Guangdong Weiye aluminium factory Co., Ltd.13 、 Zhaoqing Asia Aluminium Factory Co., Ltd.

- Q: Features of aluminum profiles

- MachinabilityThe machinability of aluminum profile is excellent. In a variety of wrought aluminum and cast aluminum alloys, and in the various states after which these alloys are produced, the machining characteristics vary considerably, which requires special machine tools or techniques.FormabilityThe specific tensile strength, yield strength, ductility, and the corresponding work hardening rate govern the amount of allowable deformation.RecyclingAluminum is highly recycled, and the characteristics of recycled aluminum are almost the same as those of native aluminum.

- Q: What are the anti-static properties of aluminum profiles?

- Aluminum profiles possess excellent anti-static properties due to their inherent electrical conductivity. This conductivity allows them to easily dissipate static charges and prevent the accumulation of static electricity. As a result, aluminum profiles are widely used in applications where static electricity can cause damage or pose a safety hazard. These profiles can be found in industries such as electronics, automotive, aerospace, and manufacturing, where they are used for applications such as conveyor systems, protective enclosures, and grounding components. The anti-static properties of aluminum profiles ensure a safe and reliable operation by minimizing the risks associated with static electricity, including electrostatic discharge (ESD) damage, fire hazards, and interference with sensitive electronic equipment.

- Q: Excuse me, aluminum oxidation and electrophoresis have what different?

- Main features of high-grade electrophoresis aluminum:1, with a strong film hardness, impact resistance2, with a high adhesion to the film, not easy to fall off and aging3, aluminum oxide than the more strong wear resistance, weather resistance, alkali resistance4, the surface color is rich, beautiful, has the mirror like luster effectAluminum electrophoresis processing in oxidized aluminum on the basis of better quality than the oxidized aluminum chip. The price is relatively good point.

- Q: Can aluminum profiles be used in material handling equipment manufacturing?

- Yes, aluminum profiles can be used in material handling equipment manufacturing. Aluminum profiles are lightweight, durable, and have excellent strength-to-weight ratio, making them suitable for constructing various components such as frames, supports, and conveyors in material handling equipment. Additionally, aluminum profiles offer versatility in terms of customization and can be easily assembled, making them a popular choice in this industry.

- Q: This question asks about potential health hazards related to the use of aluminum profiles in construction.

- <p>There are minimal health risks associated with using aluminum profiles in building construction. Aluminum is a non-toxic metal and does not emit harmful substances. However, during the manufacturing process, if not properly controlled, there might be concerns related to dust and fumes. Additionally, aluminum can react with other materials, potentially causing corrosion or weakening the structure. It's important to ensure that aluminum profiles are used in accordance with safety standards and guidelines to mitigate any potential risks.</p>

Send your message to us

Aluminum Standard Industrial Aluminium Extrusion Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords