9,000 Kilogram Aluminum Sheet Coil Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

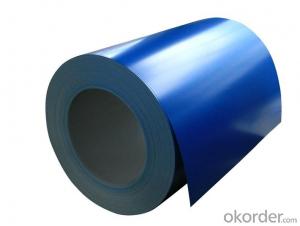

Featuresof PVDF Aluminum Coil:

1. Adoptingprecision rolling coating technology, our PE coated coil can ensure excellentadhesive without coating omission.

2. For the PVDFcoated aluminum sheet we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

Raw Materialof the PVDF Coated Aluminum Coil:

1. AluminumCoil: high strength aluminum with alloy of AA1100 (aluminum alloy is availablewith AA3003, AA3005, AA5005 according to customer)

2. SurfacePaint: PE, PVDF and special paints.

Specificationof the PVDF Coated Aluminum Coil:

Width: 20mm~1590mm

Thickness:0.06mm~1.0mm

ExternalDiameter: ≤ 1500mm

InternalDiameter: 405mm, 505mm, 150mm, 75mm

Coil weight:≤ 4000kg

Performance and usage

PVDF coated aluminumcoils are specially processed through the technics of roller coating and bakingwith precise paints from BECKER INDUSTRIAL COATINGS in

Performance of the coating

Aluminum Thickness | Coating Thickness | MEK | T Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥25μm | ≥100 Times | ≤2T | 50kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.28mm | ≥25μm | ≥100 Times | ≤2T | 20kg•cm | 0 Grade | ≥HB | no change within 2 hours |

Color ofCard

Our PVDF coated aluminum coil is made offluorine carbon resin, pigment, ester solvent after high temperature roastingand baking. The paint of this PVDF coated aluminum coils are solidified to dryfilm with super weather resistance. PVDF coating also can be classified astraditional PVDF and nanometer PVDF coating.

A. Traditional PVDF Coating, with KYNAR500 PVDF and two or three times forcoating and baking, has good properties of anti-acid, anti-alkali and isdurable in atrocious weather and environment, keeping 15 years no unwontedfading. In view of these facts, we recommend this PVDF coated aluminum coilsare applied for external wall cladding.

B. Nanometer PVDF Coating, which different with traditional PVDF, is the clearcoating. It contains nanometer element, which can protect panel from pollution,because nanometer has self-cleaning effect, it is easy to get rid of dust andpollution by raining or water.

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, soit is suggested all panels are placed in one order for same project. And keepsame direction as arrow on protective film when installing to avoid any colordifference by vision.

- Q: Can aluminum coils be used for heat transfer applications?

- Yes, aluminum coils can be used for heat transfer applications. Aluminum is known for its excellent thermal conductivity, which means it is highly effective in transferring heat. Aluminum coils are commonly used in various heat transfer applications such as air conditioning systems, refrigeration units, and heat exchangers. The lightweight and corrosion-resistant properties of aluminum also make it a popular choice for these applications. Additionally, aluminum coils can be easily shaped and formed, allowing for efficient heat transfer in complex systems.

- Q: My front door is scraping the aluminum frame door jam thing on the bottom. Also underneith the door itself it seems like there is a huge aluminum device covering the whole bottom of it and an aluminum weather stipper built into that. Is my only option to have the door pulled off. Or could I maybe grind of file down the aluminum on the bottom?

- Check your hinges first. typically your upper hinge has become loose or bent. If it is bent you could use wood 2X4 as lever under bottom corner and pry it back into position.

- Q: Can aluminum coils be used in the production of architectural façades?

- Yes, aluminum coils can be used in the production of architectural façades. Aluminum is a popular choice for façades due to its lightweight nature, durability, and versatility. Aluminum coils can be easily formed and shaped to create various architectural designs, making them suitable for use in the construction of façades.

- Q: How do aluminum coils perform in high-temperature applications?

- Aluminum coils perform exceptionally well in high-temperature applications. Aluminum is known for its excellent heat conductivity and high melting point, allowing it to withstand extreme temperatures without losing its structural integrity. This makes aluminum coils a popular choice for various industries that require heat transfer and dissipation, such as automotive, aerospace, and HVAC systems. One of the key advantages of aluminum coils in high-temperature applications is their ability to efficiently transfer heat. Aluminum has a thermal conductivity that is much higher than other commonly used metals, such as copper or steel. This means that aluminum coils can quickly and effectively transfer heat from one area to another, ensuring efficient heat dissipation and preventing overheating. Additionally, aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), which is significantly higher than many other metals. This allows aluminum coils to withstand high temperatures without deforming, warping, or losing their structural integrity. Their stability at high temperatures makes them suitable for applications where heat resistance is crucial, such as in engine cooling systems or industrial ovens. Furthermore, aluminum coils are lightweight compared to other metals, which is another advantage in high-temperature applications. Their low density allows for easier handling and installation, reducing the overall weight of the system. This is particularly important in industries like automotive and aerospace, where weight reduction is a significant factor for improving fuel efficiency and overall performance. In summary, aluminum coils are highly reliable and perform exceptionally well in high-temperature applications. Their excellent heat conductivity, high melting point, and lightweight properties make them an ideal choice for industries that require efficient heat transfer, heat dissipation, and heat resistance.

- Q: How do you clean and maintain aluminum coils?

- To clean and maintain aluminum coils, you can follow a few simple steps. First, gather the necessary materials, including a soft brush or vacuum cleaner, a mild detergent or coil cleaner, a water hose, and a spray bottle. Start by turning off the power supply to the unit and ensuring that it is safe to proceed. Next, remove any debris or loose dirt from the coils using a soft brush or a vacuum cleaner with a brush attachment. Be gentle to avoid damaging the fragile fins of the coils. Once the loose dirt is removed, mix a solution of mild detergent or coil cleaner with water in a spray bottle. Spray the solution onto the coils, ensuring that it covers the entire surface. Let it sit for a few minutes to allow the solution to penetrate the dirt and grime. After the solution has had time to work, use a soft brush or a soft cloth to gently scrub the coils. Be careful not to apply excessive pressure or use abrasive materials, as this could cause damage. Pay extra attention to any areas with stubborn dirt or buildup. Once you have thoroughly cleaned the coils, rinse them off with a water hose. Ensure that all the detergent or coil cleaner is completely washed away. Make sure to direct the water flow in the opposite direction of the air flow to avoid pushing debris further into the coils. After rinsing, allow the coils to dry completely before turning the power supply back on. This will prevent any potential electrical hazards. You can use a fan or leave the coils to air dry naturally. To maintain the cleanliness of the coils, it is recommended to clean them at least once a year or more frequently if the unit is exposed to heavy dirt or debris. Regularly inspecting the coils for dirt buildup and promptly cleaning them will help maintain the efficiency and extend the lifespan of the aluminum coils.

- Q: Can aluminum coils be used for electrical enclosures?

- Yes, aluminum coils can be used for electrical enclosures. Aluminum is a lightweight and durable material that provides excellent electrical conductivity and heat dissipation properties. It also has good corrosion resistance, which makes it suitable for various environmental conditions. Aluminum coils can be easily formed into different shapes and sizes, making them versatile for enclosure designs. Additionally, aluminum is a cost-effective option compared to other metals like stainless steel. However, it is important to ensure proper insulation and grounding when using aluminum coils for electrical enclosures to prevent any electrical hazards.

- Q: Is it possible to utilize a band saw for cutting an aluminum coil?

- <p>Yes, you can use a band saw to cut an aluminum coil. Band saws are versatile and can cut a variety of materials, including aluminum. However, it's crucial to use the right blade designed for metal cutting. Ensure the blade is sharp and has the appropriate teeth pitch for aluminum to avoid damaging the material or the blade. Adjust the speed to a lower setting to prevent overheating and ensure a clean cut. Always follow safety precautions and wear protective gear when operating power tools.</p>

- Q: Are aluminum coils suitable for food and beverage packaging?

- Food and beverage packaging can indeed utilize aluminum coils. Aluminum, being a versatile material, offers numerous advantages for packaging purposes. Its lightweight nature makes transportation and handling a breeze. Furthermore, its exceptional resistance to corrosion ensures that the packaging remains intact, safeguarding the contents from external elements. Additionally, aluminum boasts excellent thermal conductivity, enabling efficient heat transfer, which proves advantageous for temperature-sensitive food and beverage items. Moreover, it acts as a formidable barrier, impermeable to light, moisture, and oxygen, thereby maintaining the quality and freshness of the packaged goods. Furthermore, aluminum's recyclability and reusability make it an environmentally friendly choice for packaging. Consequently, aluminum coils emerge as a dependable and fitting option for food and beverage packaging, courtesy of their durability, protective properties, and sustainability.

- Q: I bought a house that is older with aluminum windows, and the last owner did not seem to clean them for quite some time. The aluminum frames are a silvery milky white color and my neighbors that have the same windows look like chrome. I have brushed these windows with scrub brushes and green scouring pads even aluminum wheel cleaner, now my frame is a clean milky grey color, it just isnt polished like my neighbor has it, his is like chrome. I have tried silver polishes and this doesn't remove the grey film either - i need something stronger. Can anyone help???

- Fistly give them a good clean, next get some marine polish-I've seen it at Halfords, and buff your window frames to a glossy shine.

- Q: I know this question is not so bright, but I am very curious why do we recycle aluminum cans? Is it that they are not biodegradable?

- Save the Rainforest! Recycle Aluminum! Did you know that aluminum comes from the ore Bauxite? And that bauxite is mined in the rainforest? Every time you throw away an aluminum can, that's one less that is being recycled, and one more can's worth of bauxite that needs to be mined from the rainforest. The bad thing about mining bauxite, just like any other ore, is that it is in the ground. Since bauxite is mined in the rainforest, there are tons of trees growing on top. In order to get to the bauxite, the trees have to be clear-cut and are usually burned since there main opperation is to mine the ore, not harvest lumber. This puts a lot of pollution into the air from the trees burning and the fossil fuels spent for the machinery to take them down. Once the land is clear, mining begins, burning even more fossil fuels. Then the ore is shipped to a facility that turns the ore into aluminum (another energy-expensive process) and then the aluminum is finally shiped to us (again, more energy, i.e. fossil fuels spent) so that we can then, finally, make cans out of them. So why don't we just make new cans out of the old ones when we are done with them? They are already here, no need for shipping. They are free, just need to be trasported to the recycling facility. And we don't have to cut rainforests to get more aluminum if we use what we've already got. Some day we will be mining our landfills because we've irresponsibly and selfishly used up our resources elsewhere. Hope this answers your question and gives you the motivation to start recycling!

Send your message to us

9,000 Kilogram Aluminum Sheet Coil Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords