Aluminum Roofing Coil Prices for Different Applications in Different Alloys

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

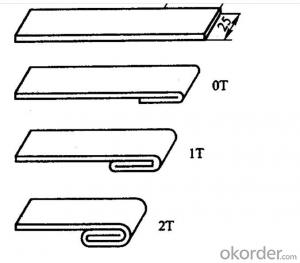

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: renovations...

(3).Advertisement: display , signboards, fascia, shop fronts...

3. Feature of Aluminum

In 1954, there were 75 registered aluminum alloys. Today, there are more than 530 registered active compositions and that number continues to grow. That underscores how versatile and ubiquitous aluminum has become in our modern world. So what are aluminum alloys and why are they important?

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

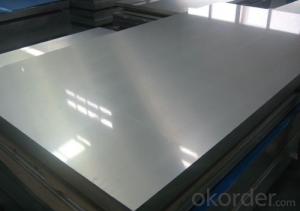

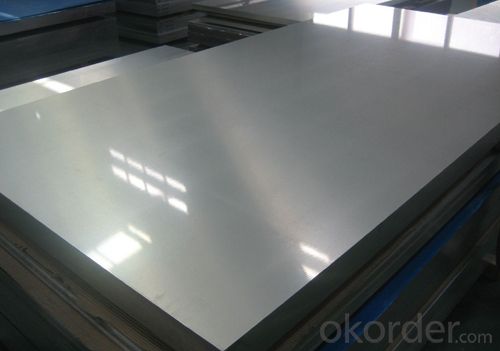

5. Image of Aluminum

6. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: I recently had to have a course of B-12 injections (my digestive system was not properly absorbing other forms). While I felt a significant improvement in mood, energy and memory, I was very concerned to discover that the B-12 shot came with a little something extra: aluminum! I'm wondering if the benefits outweigh the potential risks - why is aluminum placed in the injection? (Are there metal free versions out there?)

- Dietary okorder

- Q: Are aluminum coils suitable for high-strength applications?

- In comparison to materials like steel, aluminum coils generally have a lower tensile strength, making them unsuitable for high-strength applications. Additionally, aluminum is more susceptible to deformation when exposed to heavy loads due to its lower strength-to-weight ratio. Nonetheless, there are certain aluminum alloys like the 7000 series that have been developed to increase their strength, making them suitable for industries like aerospace and automotive that prioritize lightweight properties and moderate strength. However, when it comes to applications that demand the highest level of strength, steel or other high-strength materials are typically preferred over aluminum coils.

- Q: How do aluminum coils contribute to energy-efficient lighting installations?

- Aluminum coils contribute to energy-efficient lighting installations by providing excellent thermal conductivity, which helps dissipate heat efficiently. This reduces the energy consumed by the lighting system and extends the lifespan of the bulbs. Additionally, aluminum coils are lightweight, durable, and corrosion-resistant, making them suitable for various lighting applications.

- Q: What are the different coil handling options available for aluminum coils?

- Aluminum coils have several options for handling, depending on the user's preferences and specific requirements. Some commonly used options include: 1. Coil Cradles: These are horizontal racks or frames that provide support and stability for aluminum coils during storage or transportation. They come in various sizes and designs to accommodate different coil dimensions. 2. Coil Cars: These mobile platforms have lifting mechanisms to easily move aluminum coils between different processing stations. They can be manually operated or automated, depending on the desired level of automation. 3. Coil Turnstiles: These rotating devices hold multiple coils vertically, allowing for easy access to individual coils without heavy lifting or rearranging. They are ideal for high-volume production environments that require quick coil changeovers. 4. Coil Upenders: Specialized equipment used to rotate or flip aluminum coils to change their orientation. They are useful for loading or unloading coils in a vertical position or for specific processes that require a particular coil orientation. 5. Coil Lifters: Specifically designed lifting devices for aluminum coils. They have adjustable arms or clamps to securely grip the coil for safe and efficient lifting. Available in manual, semi-automatic, and fully automated models. 6. Coil Tippers: Used to tilt or incline aluminum coils for various purposes such as coil feeding or inspection. They can be operated manually or powered by hydraulic or pneumatic systems. 7. Coil Stackers: Used to neatly stack and store aluminum coils vertically. They have adjustable arms or forks to accommodate different coil sizes, optimizing storage space and ensuring easy access when needed. These examples showcase the variety of coil handling options available for aluminum coils. Each option has its own advantages and suitability for different applications or industries. Careful consideration of specific requirements and constraints is essential when selecting the most appropriate coil handling solution.

- Q: What is the maximum coil diameter for aluminum coils?

- The specific application and manufacturing process can cause variation in the maximum coil diameter for aluminum coils. Generally, aluminum coils have a maximum diameter ranging from 60 inches (152.4 cm) to 120 inches (304.8 cm). Factors like production equipment size, aluminum sheet thickness and width, and facility handling capabilities determine this diameter limit. To ascertain the specific maximum coil diameter for a particular aluminum coil product, it is essential to consult the manufacturer or supplier.

- Q: What house hold materials contain 100% pure aluminum. or where can i buy it. im making thermite, which ive made before so don't say, its dangerous don't do it, but do i need 100% pure aluminum or will some aluminum alloy with like 90% aluminum work?????

- Aluminum foil is your best bet. According the the Reynold's wrap web site, their foil is 98.5% aluminum.

- Q: How do aluminum coils contribute to improved building aesthetics?

- Improved building aesthetics can be achieved through the use of aluminum coils in several ways. To begin with, sleek and modern exterior finishes can be created for buildings using aluminum coils. Various finishes, such as brushed, anodized, or painted, can be applied to the coils, providing a wide range of design possibilities. Architects and designers can thus achieve their desired aesthetic vision for the building with the help of this versatility in finishes. Furthermore, aluminum coils offer the advantage of being easily shaped and formed into different profiles, resulting in a unique and customized look for buildings. By bending, cutting, or perforating the coils, intricate patterns or architectural details can be created, enhancing the overall aesthetics of the structure. This flexibility in shaping allows for the creation of visually appealing designs that can make a building stand out. Moreover, aluminum coils possess the qualities of being lightweight yet durable, making them an ideal choice for cladding systems. Using aluminum coils as exterior cladding can give buildings a modern and clean appearance. The lightweight nature of the coils also makes installation easier and more cost-effective, ultimately contributing to improved building aesthetics. Additionally, the use of aluminum coils aligns with sustainable building practices and environmentally friendly designs. Aluminum is a highly recyclable material, and buildings that incorporate aluminum coils can be seen as more visually appealing due to their eco-friendly attributes. This reflects the values of the project and its occupants. In conclusion, aluminum coils contribute to improved building aesthetics through their wide range of finishes, their ability to be shaped and customized, their lightweight and durable nature for cladding, and their promotion of sustainable design practices.

- Q: Can aluminum coils be used for HVAC condenser coils?

- Indeed, HVAC condenser coils can utilize aluminum coils. In recent times, aluminum coils have gained significant popularity owing to their myriad benefits over conventional copper coils. With their lighter weight and enhanced durability, aluminum coils exhibit superior resistance to corrosion. Additionally, they boast exceptional heat transfer properties that enable efficient refrigerant cooling. Furthermore, aluminum coils prove to be more cost-effective and environmentally sustainable in comparison to copper coils. All in all, opting for aluminum coils for HVAC condenser coils is a viable and advantageous choice.

- Q: 1) From What does aluminium derive its name?2)From which ore is aluminium extracted?3)Which country produces more aluminium than any other?4)An American and French scientist both patented the current process used to produce aluminium, what were there names?5)Who is credited with having been first to produce metallic aluminium?

- 1) From What does aluminium derive its name? Ancient Greeks and Romans used aluminium salts as dyeing mordants and as astringents for dressing wounds; alum is still used as a styptic. In 1761 Guyton de Morveau suggested calling the base alum alumine. In 1808, Humphry Davy identified the existence of a metal base of alum, which he at first termed alumium and later aluminum . The earliest citation given in the Oxford English Dictionary for any word used as a name for this element is alumium, which British chemist and inventor Humphry Davy employed in 1808 for the metal he was trying to isolate electrolytically from the mineral alumina. 2)From which ore is aluminium extracted? Bauxite 3)Which country produces more aluminium than any other? China 4)An American and French scientist both patented the current process used to produce aluminium, what were there names? Hall and Héroult 5)Who is credited with having been first to produce metallic aluminium? Friedrich W?hler

- Q: How do aluminum coils contribute to thermal insulation in buildings?

- Aluminum coils contribute to thermal insulation in buildings in several ways. Firstly, aluminum is an excellent conductor of heat, meaning it can effectively transfer heat away from the building's interior. This allows for efficient cooling during hot summer months, as the aluminum coils can absorb and dissipate the heat, preventing it from entering the building. Secondly, aluminum coils can be integrated into HVAC systems to regulate the temperature inside the building. By circulating cool air through the coils, the aluminum helps to maintain a comfortable temperature, reducing the need for excessive energy consumption. Additionally, aluminum coils can be used as part of an insulation system known as radiant barrier insulation. This involves placing reflective aluminum foil on the inside of walls, roofs, or attics, which helps to reflect radiant heat back towards its source. This prevents the transfer of heat into the building, keeping it cooler in the summer and reducing the need for air conditioning. Moreover, aluminum coils are lightweight and easy to install, making them a cost-effective choice for thermal insulation in buildings. They can be easily shaped and fitted into various spaces, ensuring optimal coverage and maximum thermal efficiency. Overall, aluminum coils play a crucial role in thermal insulation by effectively dissipating heat, regulating temperature, and reflecting radiant heat. Their versatility and efficiency make them a valuable component in creating energy-efficient and comfortable environments within buildings.

Send your message to us

Aluminum Roofing Coil Prices for Different Applications in Different Alloys

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords