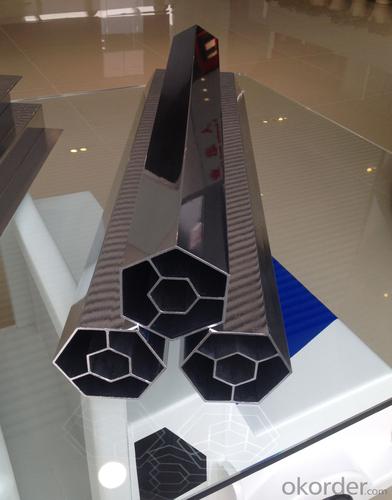

Aluminum Pipes for Vehicle Structure Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, electrophoresis, Mill,etc |

Colour | -- |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Car body; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: What's the difference between 3003 tubes and 6063?

- 6063 Aluminum Alloy composition range specified in the national standard GB/T3190 in the value of different chemical components, will get different material properties, chemical composition when the range is large, the difference of the performance fluctuates in a large range, so that the performance profiles will be unable to control.

- Q: Can aluminum pipes be used for irrigation valves?

- Certainly! Aluminum pipes are suitable for irrigation valves. They are commonly utilized in irrigation systems because of their lightweight, durable, and corrosion-resistant properties. These pipes are an excellent option for conveying water as they can endure various weather conditions without rusting or deteriorating. Moreover, the installation of aluminum pipes is effortless, which makes them a cost-effective alternative for irrigation systems. However, it is crucial to ensure that the aluminum pipes utilized for irrigation valves are adequately coated or treated to prevent any chemical reactions with water or soil. In conclusion, aluminum pipes are an appropriate choice for irrigation valves and can efficiently distribute water to crops and plants.

- Q: I have 6 60CM long diameter 5MM aluminum tubes, which are used on the model. I want to take it home. It is too small for me to take a plane. Can I take it with me? For advice, fly from Nanjing, transfer in Xi'an, check security two times.

- In general can not carry only checked, you can specify at check-in, see if you can carry, if not, the airport where there are special packing, good consignment packaging.

- Q: Is it better to choose a radiator, a copper tube or a steel tube?

- If it is an industrial radiator, such as a boiler heat exchanger, it is a good steel tube.If it is household, of course, copper aluminum tube is good.You said radiator, use the occasion to be more specific.

- Q: Can aluminum pipes be used for electrical grounding systems?

- Indeed, aluminum pipes are suitable for electrical grounding systems. Due to their excellent conductivity and minimal electrical resistance, aluminum is frequently employed as a material for grounding. This choice proves both effective and economical as it allows for efficient dissipation of electrical charges and facilitates the safe flow of electrical currents into the ground. Nevertheless, to uphold the integrity of the grounding system, it is imperative to employ appropriate installation methods and connectors to prevent corrosion. Moreover, adherence to local electrical codes and regulations is crucial when opting for and installing aluminum pipes for electrical grounding objectives.

- Q: My company plans to rust aluminum 15 Phi Phi 8 hit a row of holes, then Phi 8 Phi 15 in aluminum pipe welding, welding oxyacetylene welding using plan copper welding current, using nitrogen or nitrogen and hydrogen in welding. As a result, many welding leaks and air holes were found in aluminum tube welding, and the welding success rate was low. How can I improve it?

- Aluminum alloy welding is most afraid of hydrogen and nitrogen. Oxyacetylene welding itself is hydrogen protection, but the welding of aluminum alloy is not good.

- Q: An aluminum tube, about 3 meters long, 5 cm in diameter, what is the price?

- Would you like to know how large and thick the aluminum tube you are talking about, and the 6061 material is generally 24 yuan a kilogram

- Q: Are aluminum pipes suitable for chemical storage facilities?

- Due to their potential reactivity with certain chemicals, aluminum pipes might not be the optimal choice for chemical storage facilities. Although aluminum is typically resistant to corrosion, it can still undergo reactions with certain acids and alkaline substances, resulting in damage and potentially jeopardizing the pipes' integrity. Moreover, aluminum pipes may lack the essential strength and durability necessary for the safe handling and storage of chemicals. To identify the most suitable pipes for specific chemical storage requirements, it is recommended to seek advice from a chemical engineer or a material compatibility expert.

- Q: Air conditioning copper aluminum tube life is generally a few years?

- The air conditioning is broken on the compressor, not bad on the copper aluminum tube, do not consider this problem.

- Q: Are aluminum pipes suitable for nuclear power plants?

- Aluminum pipes are unsuitable for nuclear power plants as they have certain limitations. Despite being lightweight and corrosion-resistant, aluminum has drawbacks that make it unfit for use in this context. The primary concern with aluminum pipes in nuclear power plants is their relatively low melting point. Operating temperatures in nuclear power plants far exceed aluminum's melting point of approximately 660 degrees Celsius. This means that the pipes can deform or fail when exposed to the high temperatures, compromising the system's integrity. Another major issue is aluminum's low neutron absorption cross-section. Neutrons play a crucial role in nuclear reactions, and materials used in nuclear power plants must be capable of absorbing these neutrons to control the reaction and prevent a runaway chain reaction. Unfortunately, aluminum has a relatively low neutron absorption rate, making it unsuitable for critical areas where neutron absorption is necessary. Moreover, aluminum is prone to corrosion in specific conditions, particularly in the presence of water or moisture. Given that nuclear power plants use water as a coolant and for other purposes, the corrosive environment can lead to the deterioration of aluminum pipes over time. This corrosion compromises the pipes' structural integrity, resulting in leaks or failures with potentially severe consequences in a nuclear power plant. Considering these factors, materials like stainless steel or other high-performance alloys are preferred over aluminum in nuclear power plants. Stainless steel, for instance, exhibits higher melting points, better neutron absorption properties, and superior resistance to corrosion. In summary, the use of aluminum pipes is not suitable in nuclear power plants due to their low melting point, inadequate neutron absorption properties, and susceptibility to corrosion. Instead, materials such as stainless steel are preferred for their higher temperature resistance, superior neutron absorption rates, and better corrosion resistance. These alternatives ensure the safety and reliability of nuclear power plant operations.

Send your message to us

Aluminum Pipes for Vehicle Structure Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords