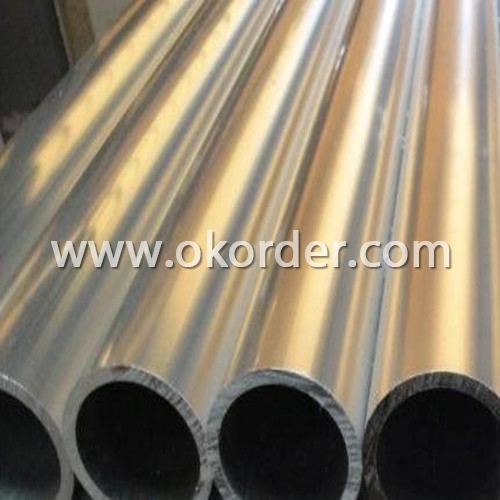

Aluminum Pipes 8xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Aluminum Pipes 8XXX

Alloy Number | AA 8XXX |

Temper | O, F,H112,T4,T5,T6,T3,T8 |

Thickness | 0.5-50mm |

Length | <=13m |

Diameter | Outer: 9-500mm |

Standard | GB/5237.2-2004, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

2. Usage/Applications of Aluminum Pipes 8XXX

Aluminum pipes are widely used for building construction, housing decorations, industry & agriculture & architecture usage etc.

3. Packaging & Delivery of Aluminum Pipes 8XXX

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of Aluminum Pipes 8XXX

Casting--extruding--cutting--coating—further processing--packing

- Q: Can aluminum pipes be used for heat transfer applications?

- Yes, aluminum pipes can be used for heat transfer applications. Aluminum has good thermal conductivity, which allows it to efficiently transfer heat. Additionally, aluminum pipes are lightweight and corrosion-resistant, making them suitable for various heat transfer processes such as in heating systems, air conditioning units, and heat exchangers.

- Q: Can aluminum pipes be used for heat exchangers?

- Yes, aluminum pipes can be used for heat exchangers. Aluminum is widely used in the manufacturing of heat exchangers due to its excellent thermal conductivity and corrosion resistance properties. Additionally, aluminum pipes are lightweight, which makes them easier to handle and install in heat exchanger systems.

- Q: How are aluminum pipes manufactured?

- Extrusion, a well-known process, is employed in the manufacture of aluminum pipes. This process involves the passage of a heated aluminum billet or log through a specifically shaped die, resulting in the creation of a desired cross-sectional shape. The initial stage of the manufacturing process entails the careful selection of a high-quality aluminum alloy. Subsequently, the alloy is subjected to heating in a furnace, usually at temperatures ranging from 750 to 950 degrees Fahrenheit (400 to 500 degrees Celsius). This heating renders the material malleable and facilitates ease of shaping. Upon reaching the desired temperature, the aluminum billet is moved to the extrusion press. This press comprises a chamber for billet placement and a ram that exerts pressure to propel the billet through the die. The final shape of the pipe is determined by the die. During the billet's passage through the die, it undergoes plastic deformation, adopting the shape of the die opening. The application of high pressure by the ram ensures precise control over the pipe's dimensions and surface finish. Following extrusion, the aluminum pipe is subjected to cooling in either a water bath or an air cooling system. This cooling process leads to the hardening and stabilization of the pipe's shape. Subsequently, the pipe is cut to the desired length, using commonly a saw or other cutting tools. The concluding step encompasses any necessary finishing processes, such as straightening, deburring, or surface treatment. These processes are essential in guaranteeing that the aluminum pipe fulfills the required specifications and quality standards. Overall, the extrusion process enables the efficient and cost-effective production of aluminum pipes, characterized by consistent dimensions and exceptional mechanical properties. Consequently, aluminum pipes have gained popularity across various industries, including construction, automotive, aerospace, and plumbing.

- Q: We bought the house in 2008 Frestech refrigerator, 2 door, 179L, when the price is 1700 yuan. It's been four and a half years now. The refrigerator is broken. The refrigeration began to heat up in three hours, and the meat in the freezer became soft and soft. Call the customer service, please master home repair, the master told us that the cooling pipe corrosion leak, to add 450 yuan for copper pipe. Also said that after 2008 refrigerators produced, the basic cooling tube is iron or aluminum, in order to control costs. After the bad, you have to pay additional money to buy a new refrigerator, so as to update. Otherwise, like the previous refrigerator is copper tube, 20 years are not bad, manufacturers are unable to survive. Alas, are manufacturers today so black hearted?

- Frestech refrigerator belongs to the second tier brands, with the greatest likelihood of iron pipe.At present, the domestic refrigerators are basically aluminum alloy tubes or iron pipes, the main reason is to reduce costs. In addition, the current refrigerant does not have any corrosive, and iron pipe is entirely possible.However, the exposed section, that is, the section of the compressor links, or copper tube, because it leaks in the air, the cold pipe will condense the moisture in the air, forming water droplets, if the iron pipe, it will rust easily. The main pipe is insulated by the insulation layer and is not in contact with the air. Therefore, the water pipe can not be collected, and the iron pipe is feasible.

- Q: 6063, how to prevent cracking aluminum tube, variant manual bending machine bending machine bending, what should pay attention to?No one knows?

- 6063, aluminum tube plasticity is very good, if you want to bend, it is recommended to return the fire, reduce the hardness, bending after quenching, bend pipe bend can be.

- Q: Do aluminum pipes require any special coatings?

- Yes, aluminum pipes often require special coatings for protection against corrosion and to enhance their durability.

- Q: Do aluminum pipes require any special maintenance?

- Aluminum pipes do not require any special maintenance in general. However, it is important to keep them clean and free from any debris or substances that may cause corrosion. Regular cleaning with mild soap and water is sufficient to maintain the appearance and functionality of aluminum pipes. Additionally, it is advisable to inspect and repair any leaks or damages to ensure the longevity and efficiency of the piping system. Overall, aluminum pipes are known for their durability and resistance to rust, making them a low-maintenance option for various applications.

- Q: Can anodized aluminum 6061-T6 surface be oxidized?

- The so-called T6 is a kind of heat treatment, the main process is rolling solid solution and aging, these steps is to let the inner Aluminum Alloy changed, the metal can reach high strength and long deformation, anodic oxidation of our workpiece can have better conductivity and not the impurity content of workpiece the 6061 is too high, a low impurity content of his aluminum alloy aluminum is much less than, so the conductivity of aluminum has good ductility and high anodic oxidation and chemical polishing, is a good choice.

- Q: Are aluminum pipes suitable for vacuum systems?

- Yes, aluminum pipes can be suitable for vacuum systems depending on the specific requirements and conditions of the system. Aluminum is a lightweight and corrosion-resistant material, making it a popular choice for various applications, including vacuum systems. However, it is important to consider factors such as the level of vacuum required, the temperature range, and the potential for outgassing. In certain cases, aluminum may not be the best choice, especially for high vacuum applications or systems that require extremely low levels of outgassing. In such cases, materials like stainless steel or titanium may be more suitable. It is crucial to consult with experts or engineers who specialize in vacuum systems to determine the most appropriate material for a specific vacuum system.

- Q: Do aluminum pipes expand or contract with temperature changes?

- Aluminum pipes expand with temperature increases and contract with temperature decreases. This is due to the property of thermal expansion, which is the tendency of a material to change in size, volume, or shape in response to temperature changes. As aluminum is heated, the atoms within the metal gain energy and vibrate more, causing the material to expand. Conversely, when the temperature decreases, the atoms lose energy and vibrate less, resulting in contraction. It is important to consider these thermal expansion and contraction effects when designing and installing aluminum pipes to ensure proper fit and functionality.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Pipes 8xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords