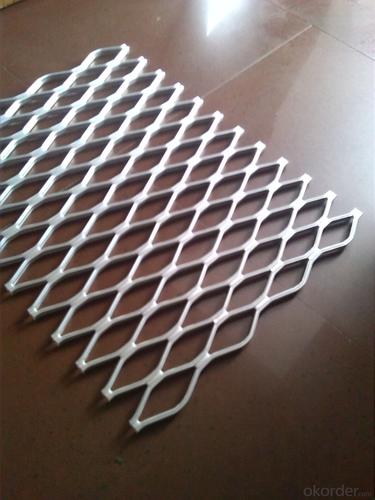

Aluminum Square Tube Profiles Nets & Mesh

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

The detail descriptions of aluminum profile as bellowing:

Alloy Aluminum 6063,6061,6005,6082 or customer nominated | |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: What are the differences between the aluminum profile material and the anodized aluminum profile? Where are they used? If it is necessary to spray the fluorocarbon paint on aluminum, do it on the basis of anodic oxidation or on the aluminum profile material?

- The surface of the material is not oxidized. The oxidized aluminum profile has a smooth and beautiful surface. According to your requirements, choose material

- Q: This question asks for a list of various types of coatings applied to aluminum profiles to prevent corrosion.

- <p>Aluminum profiles are protected from corrosion through several types of coatings. These include: Anodizing, which forms a protective oxide layer; Powder Coating, a durable and weather-resistant finish; Electrophoretic Deposition (E-coat), offering a smooth, corrosion-resistant surface; Fluoropolymer coatings, known for their exceptional chemical resistance and UV stability; and Thermal Spray Coatings, which provide a hard, wear-resistant surface. Each method serves to enhance the aluminum's resistance to environmental factors and extend its lifespan.</p>

- Q: Is it possible to use aluminum profiles as materials for flooring?

- <p>Aluminum profiles can indeed be used for flooring materials, particularly in industrial or commercial settings. They are valued for their strength, durability, and resistance to corrosion. Aluminum profiles are often used in modular flooring systems, providing a stable and customizable base that can be easily adjusted or reconfigured. They are also appreciated for their lightweight nature, which can reduce the load on structures and facilitate installation. However, for residential applications, traditional flooring materials like wood, tile, or carpet are more common due to aesthetic and comfort considerations.</p>

- Q: This question seeks to understand the various types of aluminum profiles that are specifically used in the construction of building facades.

- <p>Aluminum profiles for facades come in various types, each serving different purposes and functions. Common types include: 1. <strong>Vertical and Horizontal Mullions</strong>: These are the primary structural elements that form the framework of the facade. 2. <strong>Transoms and Muntins</strong>: Used to divide the glass into panels, providing both aesthetic appeal and structural integrity. 3. <strong>Capping Profiles</strong>: These cover the ends of the mullions, providing a finished look and protecting the edges. 4. <strong>Cover Caps</strong>: Used to conceal the fasteners and provide a clean, streamlined appearance. 5. <strong>Angle Connectors</strong>: Facilitate the connection of different profile sections at various angles. 6. <strong>Gaskets and Seals</strong>: Ensure weatherproofing and insulation. 7. <strong>Accessories</strong>: Such as handles, locks, and hinges, which are integrated into the facade system. Each type is designed to meet specific performance requirements, such as load-bearing capacity, resistance to environmental factors, and aesthetic considerations.</p>

- Q: What specific criteria or standards must be met when employing aluminum profiles in commercial construction?

- <p>Yes, there are special requirements for using aluminum profiles in commercial buildings. These include adherence to building codes and regulations, which vary by region. Profiles must meet specific strength and durability standards to ensure structural integrity. They should also comply with fire safety and energy efficiency requirements. Additionally, the profiles need to be resistant to corrosion and weathering, and must be compatible with other building materials. Aesthetic considerations, such as color and finish, are also important to match the building's design. It's crucial to work with certified suppliers and follow proper installation procedures to meet these requirements.</p>

- Q: Can aluminum profiles be used in the construction of modular office spaces?

- Yes, aluminum profiles can definitely be used in the construction of modular office spaces. Aluminum profiles are lightweight, durable, and have excellent structural integrity, making them an ideal choice for modular construction projects. They can be easily fabricated and assembled to create various components such as walls, partitions, doors, windows, and framing systems for modular office spaces. Additionally, aluminum profiles offer great design flexibility, allowing for customization and adaptation to different office layouts and requirements. They are also highly resistant to corrosion, which is particularly beneficial in office environments where moisture and humidity can be present. Overall, aluminum profiles provide numerous advantages in terms of strength, versatility, and aesthetics, making them a popular choice for construction in modular office spaces.

- Q: Are aluminum profiles suitable for playground equipment?

- Yes, aluminum profiles are suitable for playground equipment. Aluminum is a lightweight and durable material that is commonly used in various industries, including playground equipment manufacturing. It is known for its strength and resistance to corrosion, making it suitable for outdoor applications. Aluminum profiles provide structural stability and can withstand the weight and forces exerted during play. Additionally, aluminum is non-toxic and does not rust, ensuring the safety and longevity of the playground equipment. The versatility of aluminum allows for the creation of various shapes and designs, providing endless possibilities for innovative and attractive playground structures. Overall, aluminum profiles are a suitable choice for playground equipment due to their strength, durability, and safety features.

- Q: How to identify and distinguish the inferior aluminum profile and the poor aluminum profile four?

- First, extrusion defects.Aluminum extrusion process for machine equipment is perfect, process technology is mature and whether the operation staff misconduct and other reasons, will lead to aluminum flakes, such as inclusion, delamination, chromatic aberration, distortion and other defects, affecting the quality of aluminum profiles.Second, the film thickness is thin.Industrial aluminum oxide film thickness standard should be not less than 10um (m). If the thickness is not enough, the surface of the aluminum profile is easy to rust and corrode and shorten the service life. In order to save the cost, the thickness of the oxide film is only 2 to 4um, and some even have no oxide film. It is estimated that each reduction of 1um film thickness can reduce power consumption by more than 150 yuan per ton.

- Q: This question asks about the various types of aluminum profiles that are specifically used for the purpose of insulating exterior walls.

- <p>Aluminum profiles for exterior wall insulation are crucial for thermal efficiency and structural integrity. Common types include: 1. <strong>Aluminum Cladding Profiles</strong>: These cover the insulation and provide a weather-resistant barrier. 2. <strong>Aluminum Insulation Fin Profiles</strong>: Used to create a gap for insulation material between the wall and the cladding. 3. <strong>Aluminum Casing Profiles</strong>: These encase the insulation, providing a finished look and additional protection. 4. <strong>Aluminum Angle Profiles</strong>: Used for corners and edges to maintain structural integrity. 5. <strong>Aluminum Trim Profiles</strong>: For finishing touches and to cover gaps or seams. Each type serves a specific function in the insulation system, ensuring energy efficiency and a durable exterior wall construction.</p>

- Q: This question asks about the various methods for connecting aluminum profiles using fasteners.

- <p>There are several ways to join aluminum profiles together using fasteners: 1. Bolts and Nuts: Commonly used for strong and removable connections. 2. Rivets: Provide a permanent connection, suitable for high-stress applications. 3. Screws: Offer a secure and adjustable connection, often used in furniture and construction. 4. Pins: Used for alignment and positioning, often in lighter applications. 5. Adhesives: Can be used for a more aesthetically pleasing joint, though not as strong as mechanical fasteners. 6. Welding: Although not a fastener method, it is a common way to join aluminum profiles for a permanent and strong bond. Each method has its advantages and is chosen based on the specific requirements of the application, such as strength, permanence, and ease of assembly.</p>

Send your message to us

Aluminum Square Tube Profiles Nets & Mesh

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords