Aluminum Moulding Strips - Aluminium Stucco Sheet/Aluminium Slit Coil A1060/3003/1100/1050 H14/24

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: kitchens and balconies, shutters, doors...

(2).Exterior: renovations...

(3).Advertisement: fascia, shop fronts...

3. Feature of Aluminum

Very simple Al(II) compounds are invoked or observed in the reactions of Al metal with oxidants. For example, aluminium monoxide, AlO, has been detected in the gas phase after explosion and in stellar absorption spectra.More thoroughly investigated are compounds of the formula R4Al2 which contain an Al-Al bond and where R is a large organic ligand.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

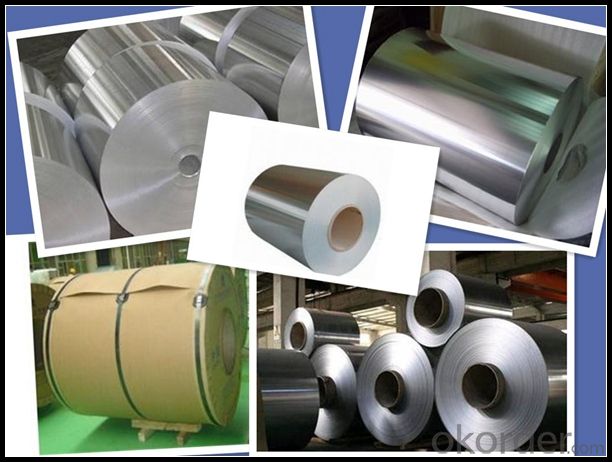

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks about the various applications of aluminum strips within the construction industry.

- <p>Aluminum strips are used in construction for a variety of purposes. They are commonly used in curtain wall systems for their lightweight and high-strength properties, providing structural support while maintaining transparency. Aluminum strips are also used in window and door frames for their durability and resistance to corrosion. In addition, they are utilized in roofing systems for their ability to withstand weather conditions and for their energy efficiency. Furthermore, aluminum strips are employed in electrical wiring and conduits due to their excellent conductivity and resistance to electrical corrosion. They are also used in the fabrication of various construction tools and equipment. Overall, aluminum strips are valued for their versatility, strength, and resistance to wear and tear in the construction industry.</p>

- Q: Describe the process of manufacturing aluminum strips.

- <p>Aluminum strips are made through a series of processes starting with the production of aluminum ingots. The ingots are heated and then rolled into thin sheets in a hot rolling mill. This process reduces the thickness of the aluminum and elongates it into a strip. The hot-rolled strips are then cooled and may undergo further cold rolling to achieve the desired thickness and hardness. After rolling, the strips may be annealed to improve their ductility and strength. The final step includes cutting the strips to the required length and packaging them for distribution. This process ensures that aluminum strips have the desired properties for various applications such as construction, automotive, and aerospace industries.</p>

- Q: What's the specialty of aluminum strip rolling?

- I don't know what raw material this enterprise produces, which is related to the process. The state has the aluminum industry cleaner production evaluation index system (issued by the Ministry of industry), the clean production standard of alumina industry and the clean production of electrolytic aluminum industry

- Q: This question asks for a comparison between aluminum strips and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum strips are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are low-maintenance and have a long lifespan, often outlasting other materials like asphalt shingles. Compared to metal roofing, aluminum strips may be more prone to denting, but they are quieter and less likely to expand or contract with temperature changes. When compared to tile or slate, aluminum is much lighter, reducing the load on the structure and installation costs. However, it may not offer the same aesthetic appeal or insulation properties. Overall, aluminum strips are a cost-effective and eco-friendly choice for roofing, especially in areas with harsh weather conditions.</p>

- Q: This question asks if it's possible to use various types of siding materials on a home's exterior to achieve a desired aesthetic.

- <p>Yes, you can use different types of siding on your home's exterior to match your style. Mixing materials such as vinyl, wood, brick, or stone can create a unique and personalized look. It's important to consider the architectural design and ensure that the materials complement each other in terms of color, texture, and style. Consult with a professional to help you choose the right combination that suits your home and preferences while also considering factors like durability, maintenance, and cost.</p>

- Q: This question asks for an explanation of the corrosion protection mechanism provided by aluminum strips.

- <p>Aluminum strips protect against corrosion through a process known as sacrificial anode cathodic protection. When aluminum is exposed to an electrolyte (like soil or water), it naturally forms a thin, protective oxide layer on its surface. This layer prevents further oxidation. In a galvanic cell, aluminum acts as the anode and corrodes preferentially, sacrificially protecting the cathode, which is usually a more noble metal like steel. The aluminum strip corrodes instead of the steel, thus preventing the steel from corroding. This method is effective because aluminum is more reactive than steel, and it corrodes at a slower rate once the initial protective layer is formed, making it a sustainable protection method.</p>

- Q: Is it possible to apply paint to aluminum strips once they have been installed?

- <p>Yes, aluminum strips can be painted after installation. However, it is essential to prepare the surface properly. This includes cleaning the aluminum to remove any dirt or grease, then lightly sanding it to create a better surface for the paint to adhere to. It is also recommended to use a primer specifically designed for metal surfaces to enhance the paint's durability and adhesion. After priming, the aluminum strips can be painted with a suitable paint, such as a high-quality acrylic or enamel paint, following the manufacturer's instructions for application and drying times.</p>

- Q: Is it possible to install aluminum siding on a historic building without compromising its aesthetic or structural integrity?

- <p>Using aluminum siding on a historic building can be done without damaging its appearance or structure if done correctly. It's crucial to ensure that the siding is installed in a manner that respects the building's historical integrity. This often means using siding that closely matches the original materials in terms of color and texture, and installing it in a way that doesn't alter the building's structural elements. Consulting with historic preservation experts and adhering to local preservation guidelines is essential to maintain the building's historic character while providing the benefits of modern siding materials.</p>

- Q: This question asks for a step-by-step guide on how to attach aluminum strips to a roof or wall.

- <p>To install aluminum strips on a roof or wall, follow these steps: 1. Measure and mark the area where the strips will be installed. 2. Clean the surface thoroughly to ensure proper adhesion. 3. Cut the aluminum strips to the required length using a hacksaw or tin snips. 4. Apply a bead of construction adhesive along the top edge of the strip. 5. Press the strip firmly into place, starting from one end and working your way along the surface. 6. Use a level to ensure the strip is straight and secure it with nails or screws at regular intervals. 7. Fill any gaps between the strips and the surface with caulk to create a watertight seal. 8. Finish with a coat of paint or sealant to match the surrounding area and protect the aluminum from weathering. Always follow the manufacturer's instructions for the specific adhesive and sealant products you are using.</p>

- Q: Is it possible to use aluminum strips for the exterior walls of a building?

- <p>Yes, aluminum strips can be used for exterior walls. They are lightweight, durable, and resistant to corrosion, making them suitable for cladding and facades. Aluminum strips can also be coated with various finishes to enhance their appearance and protect against weathering. They are commonly used in modern architecture for both aesthetic and functional purposes, offering a sleek and contemporary look while providing insulation and weather protection.</p>

Send your message to us

Aluminum Moulding Strips - Aluminium Stucco Sheet/Aluminium Slit Coil A1060/3003/1100/1050 H14/24

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords