Big Aluminum Foil - Aluminum Foil-Paper Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

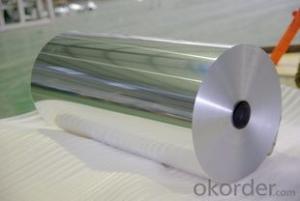

1.Description of Aluminum Foils, Aluminum Foil-paper

In North America, aluminium foil is known as aluminum foil. It was popularized by Reynolds Metals, the leading manufacturer in North America. In the United Kingdom and United States it is, informally, widely called tin foil, for historical reasons (similar to how aluminum cans are often still called "tin cans").Metallised films are sometimes mistaken for aluminium foil, but are actually polymer films coated with a thin layer of aluminium. In Australia, aluminium foil is widely called alfoil.

2.Why you choose us?

Our quelity and service is best in China!

3.Aluminum Foils, Aluminum Foil-paper Specification and Application

ALUMINIUM FOIL

ALLOY:AA1***

AA3***

AA8***

TEMPER: O H14 H16 H18 H22 H24 H26

THICKNESS: 0.006MM-0.20MM

WIDTH: 200MM-1600MM

COATING: HSL/PRIMER

STANDAR: GB/T 3198-2003

LIGHT GAUGE ALUMINUM FOIL

application:cigarette package, aseptic package, pouches, sachets

alloy:1235/8011/8079

temper:O

thickness&tolerance:0.006mm-0.009mm (±6%)

width&tolerance: 200mm-1650mm (±1mm)

mehanical properties: tensile strength (U.T.S)≥40Mpa, elongation≥1%

standard: GB/T3198 / ASTM-B209 /EN 546

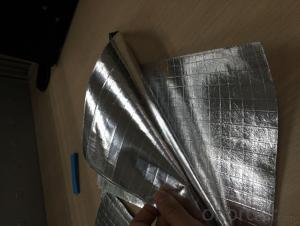

4.Aluminum Foils, Aluminum Foil-paper Pictures

5.Aluminum Foils, Aluminum Foil-paper FAQ

1)How about our payment term?

LC and TT and other.

2)Which country can we supply?

All around the world!

Production Flow of Hot Rolled Checkered Steel Plate:

1.The steel raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

2.The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, plates and slabs.

3.The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

4. Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath),electrocleaning(application of an electric current, using phosphoric acid and a cathode), etc.

5. Descaling of the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling,forging and extruding, the sheet and strip forms go through annealing after hot rolling.

6. Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

6. Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

- Q: Also, can anyone recommended how to cook it.Any suggestions helpThanks!

- Set a foil pie pan in a small skilletMelt your crayons that wayToss the foil pie pan when you';re finished.

- Q: and you know the two books relate, can i call them foil charachtersi'm specifically reffering to heathcliff (wuthering heights) and edward (twilight) and other things that seems meyer has brought in to quot;foilquot; her characters with other books.

- If you saw a carrot lying on the floor what would you do? Pick it up How come the sky is blue? It has something to do with atmosphere, i thinkDo flying fish really fly? They jump out of water and in to a bear's mouthWould you rather eat 5 bottles of tomato sauce or have to wear green for a month? Green because I love it! Do you like elevator music? I never mind itWhere did you get your phone from? Walmarts Have you ever heard the song bad touch? No Would you ever date someone 20 years older than you? Sugar Daddy much? NoDo you wish you had a hot chocolate right now? No a cappuccino When I say Australia, what is the first word that comes to mind? Mate What question would you add to this survey? Does your feet smell? How many holes are there in your underwear? 1 What color is your house? White How many windows are in the room you are in? 1 and another on the doorWhat hair color would you like to have? Auburn.

- Q: How do you fry ice cream?

- You fry the ice cream by putting a type of coating on it so it won't melt as much, during the frying process the coating gets crispy and holds the ice cream inIt's pretty goodI have a recipe that I've used before and my family loved it 1 qtvanilla ice cream or ice cream of your choice 1 cup corn flake crumbs 1/2 cup sugar 1/2 tspcinnamon Also: Chocolate syrup Whipped cream Maraschino cherries Oil Prepare 5 hours in advance Combine crumbs, sugar, and cinnamon in a shallow panLet ice cream soften slightly for 5 minutesMake 6 balls of ice cream, roll in crumb mixture until well coasted, pressing coating into ice creamWrap in aluminum foil and freeze for 5 hoursHeat oil to 450 degreesUnwrap each ball and fry in hot oil VERY BRIEFLY, about 2 secondsPlace in dessert dish, or a waffle bowl Decorate with toppings, whipped cream and a cherryServe immediately.

- Q: i did a science project on moldy cheese and i put a slice on a plate on the counter than i wrapped another slice up in aluminum foil then i wrapped another slice in cling wrapand aluminum foil molded fastest, and in second the cling wrap molded and then the one that was left out in the open didnt really mold, it just quot;sweatedquot; and was oily and discoloredso i wondered what was in aluminum foil to make the cheese mold.

- The answer is moistureThe cheese on the plate dried outmold needs waterThe sweat you saw was was oil that was squeezed out after the water evaporatedThe foil kept the moisture in and made it darkerMold does not need dark but seems to do betterThe mold spores are actually in the air, and handling the cheese to place it in the 3 places was enough to inoculate the cheese.

- Q: something to have with riceDont have lots of stuff, and dont want anything with cream.Anyone have any ideas ?xxx

- Hi.how aboutTender Baked Parmesan Chicken 1 sheet aluminum foil No-stick cooking spray 1/2 cup light or low fat mayonnaise 1/3 cup shredded Parmesan cheese 1/2 tspgarlic powder 4 boneless, skinless chicken breast halves 1/2 cup Italian seasoned dry bread crumbs Preheat oven to 425 degrees FLine shallow baking pan with foilSpray foil with cooking spray; set asideIn medium bowl, combine mayonnaise, cheese and garlic powderCoat chicken with mayonnaise mixture, then with bread crumbsPlace chicken in baking panBake 15 to 20 minutes or until lightly browned and tenderOR.THIS ONETender Onion Baked Chicken PREP TIME 5 Min COOK TIME 40 Min READY IN 45 Min INGREDIENTS: 10 chicken breast tenderloins or strips 1/4 cup margarine, melted salt and pepper to taste 1 (1 ounce) envelope dry onion soup mix DIRECTIONS: Preheat oven to 350 degrees F (175 degrees C)Place chicken in a 9x13 inch baking dishPour melted margarine over the chicken stripsSeason with salt and pepper, and sprinkle with dry onion soup mixBake 40 minutes in the preheated oven, or until chicken is no longer pink and juices run clearAND, LASTLYBaked Ranch Chicken Ingredients - 1 envelope Ranch Dressing Mix 1 cup Italian Bread Crumbs 1/4 cup Freshly Grated Parmesan Cheese 1/2 cup Butter or Margarine, melted 6 to 8 Boneless Chicken Breasts Preparation: In a shallow dish combine dressing mix, bread crumbs and Parmesan cheeseDip chicken in butter then roll in crumb mixture Place in a greased baking dish and bake at 350? Ffor 45 minutes or until juices run clearServes 6 - 8

- Q: Wehn you steam a cake, is it necessary to line the pan with parchment paper?What does it do for the cake?

- the al f can not go thru,too thick, vw also not,try arcylic

- Q: i measured 15mL of Ethyl Alcohol in a graduating cylinderThen, we marked the line of the chromatography paper with a brown marker Then, we transferred the Ethyl alcohol into to beaker and quickly covered the top of the beaker with the aluminum foilwe shaped the chromatography paper into a cylinder using a masking tapeOnce 2 minutes were over, we quickly lifted the aluminum foil, placed the chromatography paper inside the beaker, then placed the aluminum foil over the beaker again.we waited to see what was the result of the experimentThe results after the experiment we performed was that the Brown ink we marked on the Chromatography paper raised up the paper and spread into different kinds of colorsThe colors we saw when we took out the Chromatography paper were the colors Orange and Purple.my question is.why and how did those results happen??

- if you really want to lose your weight.don't worry.exercise daily with some hard workouts and drink fresh juices.for more info visit the below website.

- Q: back in the days we could see ppl's durring they sun bating, holding book looking thing below they chin, made out of aluminum foil or other reflecting matterial.to catch some extra tan on thay faceif yes whot is the% aproxis reflecting of it.we have a dispute bout it with my friends.and i said .i have a place where we can find out.thanX.

- An English wheel might be OK for a one-of-a-kind type of project, but for large production runs like Airstream campers, the compound-curved shapes are stamped out using dies and large hydraulic pressesIt's the same basic procedure used to make compound curves in car bodys or any other product made from sheet metal.

- Q: actually the thing iz zat I am sitting for a GCE o level exams and am very weak in chemistry can't even balance an equation plz help

- Right, When a chemical reaction occurs, it can be described by an equationThis shows the chemicals that react (called the reactants) on the left-hand side, and the chemicals that they produce (called the products) on the right-hand sideThe chemicals can be represented by their names or by their chemical symbolsUnlike mathematical equations, the two sides are separated by an arrow, that indicates that the reactants form the products and not the other way roundEg Aluminum + Oxygen Aluminum Oxide Al + O2 Al2O3 1.)We can balance the equation by multiplying the different atoms and molecules on each side by different amountsFirstly, multiply the aluminum atoms on the left side by 2 2Al + O2 Al2O3 2.)Now that we have 2 Al on each side, the O are not even 2:3 multiply the number of oxygen molecules on each side by one and a half (1.5), which would give three oxygen atoms on the left side (1.5 x 2 3) to match the three oxygen atoms on the right side 2 Al + 1.5 O2 Al2O3 3.)This is now balanced, but that 1.5 is a horrible thing to have in an equationWe can solve this problem by multiplying everything throughout by 2 4Al + 3O2 2Al2O3 If you count the number of atoms on each side, you will find that there are four aluminum atoms on each side and six oxygen atomsAll in all the more practice you do the better you will become, so take the time out and practice.

- Q: I am going with a family of 5 But would be nice with a 6 person tentwhat kind of foo we have sleeping bagso no campers

- In order to transport a crane it takes a trailer with over 20ton capability to hold oneAlso it can easily destroy anything in its path

Send your message to us

Big Aluminum Foil - Aluminum Foil-Paper Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords