BASF Reel to Reel Tape Packaging - Aluminum Foil Tape Synthetic Rubber Based for Seaming and Bonding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

Synthetic Rubber Based Aluminum Foil Tape is of aluminum foil as the carrier, coating with solvent based acrylic, synthetic rubber-resin, or water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Synthetic Rubber Based Aluminum Foil Tape: widely used for seaming and jointing bonding of various vapor barriers, fixing thermal fin in refrigerators. Provide fast and permanent bond performance for vapor barrier against the moisture.

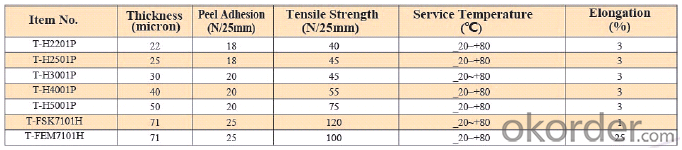

Typical Physical Reports of Synthetic Rubber Based Aluminum Foil Tape:

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1200mm; length according to customers’ requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Aluminum Foil Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: Is packaging tape easy to cut with scissors?

- Yes, packaging tape is typically easy to cut with scissors.

- Q: Can packaging tape be used for other purposes?

- Packaging tape has a wide range of uses beyond its intended purpose of sealing packages. Its strong adhesive properties and durability make it suitable for various applications. One popular alternative use for packaging tape is organizing and bundling items together. It can be used to sort and secure cables, cords, loose items, or similar objects, effectively keeping them organized. Additionally, it can be used to temporarily attach items like posters or decorations to walls or surfaces without causing any damage. Furthermore, packaging tape is great for crafting and DIY projects. Its adhesive nature allows it to create both temporary and permanent bonds between different materials. It can repair torn papers, create labels or tabs, or even make personalized stickers. Its versatility, available in different widths and lengths, makes it a valuable tool for creative endeavors. Moreover, packaging tape can be used for household fixes and repairs. Its strong adhesive properties can temporarily mend broken items or reinforce weak joints. It can also provide a temporary seal for minor leaks or cracks until a proper repair can be done. In conclusion, packaging tape's strong adhesive properties and versatility make it suitable for various purposes beyond sealing packages. Whether for organizing, crafting, or quick fixes, having packaging tape on hand can be highly useful.

- Q: What are the benefits of using UV-resistant packaging tape?

- There are several benefits of using UV-resistant packaging tape. First and foremost, UV-resistant packaging tape is designed to withstand prolonged exposure to sunlight and prevents the tape from deteriorating or degrading over time. This is especially important when shipping or storing items outdoors or in areas with direct sunlight. UV-resistant tape can maintain its adhesive properties and structural integrity for longer periods, ensuring that packages remain securely sealed. Additionally, UV-resistant packaging tape helps protect the contents of packages from damage caused by UV rays. Sunlight can cause fading, discoloration, or degradation of certain materials, such as paper, fabrics, or plastics. By using UV-resistant tape, these items are shielded from the harmful effects of UV rays, preserving their quality and appearance. Another advantage of UV-resistant packaging tape is its long-lasting adhesion. Unlike regular packaging tape, which may lose its stickiness over time when exposed to sunlight, UV-resistant tape is specifically formulated to bond tightly and securely to various surfaces. This reliable adhesion minimizes the risk of packages coming open or items getting damaged during transit. Moreover, UV-resistant packaging tape provides added peace of mind for both the sender and the recipient. By using tape that is resistant to UV rays, businesses and individuals can ensure that their packages arrive in the same condition they were sent, maintaining the professional image and customer satisfaction. This is particularly crucial when shipping valuable or delicate items that require extra protection. In conclusion, the benefits of using UV-resistant packaging tape include enhanced durability, protection against UV damage, long-lasting adhesion, and increased confidence in package integrity. By choosing UV-resistant tape, individuals and businesses can safeguard their packages and the contents within, even when exposed to prolonged sunlight.

- Q: Can packaging tape be used for sealing household or kitchen items?

- Yes, packaging tape can definitely be used for sealing household or kitchen items. It is a versatile adhesive tape that is commonly used for sealing cardboard boxes, but it can also be utilized for sealing various items in the household or kitchen. Whether you need to seal food containers, plastic bags, or even small appliances, packaging tape can provide a strong and secure seal. It is important to ensure that the surface is clean and dry before applying the tape to maximize its adhesive strength.

- Q: Is packaging tape resistant to extreme temperatures or weather conditions?

- Packaging tape is typically constructed to endure extreme temperatures and diverse weather conditions, although the degree of resistance may fluctuate depending on the tape's specific type and quality. Most packaging tapes are composed of robust materials like polypropylene or PVC, renowned for their durability and ability to withstand environmental elements. These tapes are often treated with specialized adhesives that retain their stickiness even in harsh temperatures or humid surroundings. Concerning extreme temperatures, packaging tapes are generally engineered to withstand a broad spectrum, including both frigid and scorching extremes. They can typically endure temperatures as low as -20 degrees Celsius or as high as 60 degrees Celsius without compromising their adhesive properties or becoming brittle. Similarly, packaging tapes are designed to exhibit resistance against diverse weather conditions. They are formulated to repel moisture, humidity, and UV radiation, which are prevalent factors that can deteriorate tape quality. This resistance ensures that the tape remains intact and efficient, even when exposed to rain, snow, or direct sunlight. It is crucial to note that although packaging tape is generally resistant to extreme temperatures and weather conditions, prolonged exposure to such circumstances can still impact its durability. Therefore, it is advisable to store and utilize packaging tape in a controlled environment whenever feasible to guarantee maximum effectiveness.

- Q: Can packaging tape be used for sealing packages with irregular shapes?

- Indeed, when it comes to sealing packages with irregular shapes, packaging tape comes in handy. Its flexibility and adhesive nature make it perfect for securing packages of different sizes and contours. Thanks to its strong adhesive properties, packaging tape can adhere to various surfaces, even those that are uneven or irregular, ensuring that the package remains tightly sealed during transportation. Moreover, packaging tape is known for its durability and tear-resistance, providing an added layer of protection for the package. Consequently, whether the package boasts an irregular shape or not, packaging tape proves to be a dependable and efficient choice for sealing it securely.

- Q: How do I prevent packaging tape from becoming brittle?

- To prevent packaging tape from becoming brittle, there are a few measures you can take: 1. Proper storage: Make sure to store the packaging tape in a cool, dry place away from direct sunlight. Extreme temperature changes can cause the tape to become brittle, so maintaining a consistent environment can help prolong its lifespan. 2. Avoid excessive tension: When applying the tape, try not to stretch it too tightly or apply excessive pressure. This can strain the adhesive and cause it to lose its flexibility, resulting in brittleness. 3. Use appropriate tape: Different types of packaging tapes have varying levels of durability. Depending on your needs, choose a tape specifically designed for heavy-duty or long-term use. These tapes are often made with stronger adhesives and materials that are less prone to becoming brittle. 4. Handle with care: While using the tape, handle it gently to avoid unnecessary stress. Tugging or forcefully pulling on the tape can weaken its structure and lead to brittleness. 5. Replace old tape: If you notice that your packaging tape has started to become brittle or lose its adhesive strength, it's best to replace it with fresh tape. Using old and brittle tape might compromise the security of your packaging, increasing the risk of it breaking or coming undone during transit. By following these preventive measures, you can help maintain the flexibility and durability of your packaging tape, ensuring it remains reliable for your packaging needs.

- Q: Can packaging tape be used for sealing electronics or appliances?

- It is not advisable to use packaging tape for sealing electronics or appliances. Although packaging tape is created to effectively seal cardboard boxes and packages, it is not suitable for sealing electronics or appliances due to several reasons. First and foremost, packaging tape does not offer sufficient protection against moisture or dust, which can be detrimental to electronic components. In order to prevent any damage or corrosion caused by moisture or dust particles, electronics and appliances require airtight sealing. Furthermore, packaging tape is not designed to withstand high temperatures or extreme conditions that electronics or appliances may encounter during storage or transportation. The adhesive used in packaging tape may not be able to endure heat or cold, resulting in the tape peeling off and leaving the item vulnerable and unprotected. Additionally, electronics and appliances often have delicate surfaces that can be easily scratched or damaged by the adhesive on packaging tape. Moreover, the sticky residue left behind by the tape can be challenging to remove from sensitive surfaces. Therefore, it is recommended to utilize appropriate sealing methods and materials that are specifically intended for electronics or appliances. These options may include specialized tapes, foam gaskets, or custom-fitted protective covers. It is always advisable to refer to the manufacturer's guidelines or seek professional advice when sealing electronics or appliances to ensure proper protection and functionality.

- Q: Is packaging tape resistant to oil or grease?

- Yes, packaging tape is generally resistant to oil or grease. Packaging tapes are designed to securely seal boxes and packages, ensuring that the contents inside are protected during transportation. These tapes are typically made of materials such as polypropylene or PVC, which have properties that make them resistant to various substances including oil and grease. This resistance helps to prevent the tape from deteriorating or losing its adhesion when it comes into contact with oils or greases commonly found in industrial or commercial settings. However, it is important to note that the level of resistance may vary depending on the specific type and quality of packaging tape used.

- Q: Can packaging tape be used for sealing moving boxes?

- Indeed, when it comes to sealing moving boxes, packaging tape proves to be quite useful. Its design is specifically tailored to secure boxes and packages during transit, boasting durability and strength that ensure a tight seal, preventing boxes from opening or items from spilling out. Moreover, its application is quick and effective, making it an easy-to-use option. It is worth noting that packaging tape often possesses resistance against moisture and can withstand diverse weather conditions, which makes it an ideal choice for long-distance moves or storage purposes. In summary, packaging tape is a dependable solution for sealing moving boxes and guaranteeing the safety of your belongings throughout the moving process.

Send your message to us

BASF Reel to Reel Tape Packaging - Aluminum Foil Tape Synthetic Rubber Based for Seaming and Bonding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches