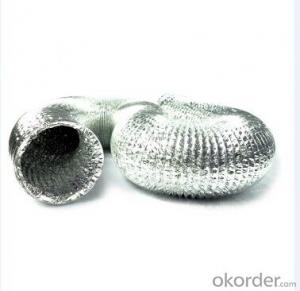

aluminum foil mylar for flexible air duct

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 78 lb/ft

- Supply Capability:

- 7878787 lb/ft/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

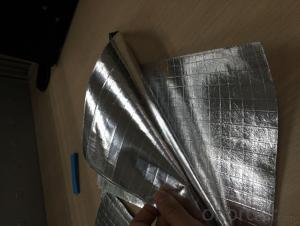

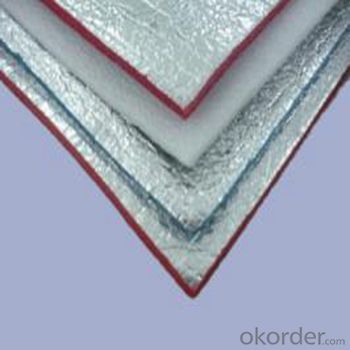

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

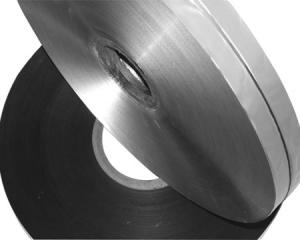

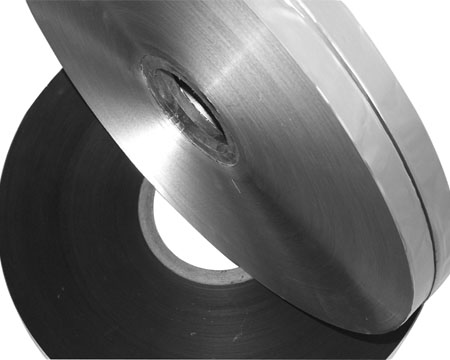

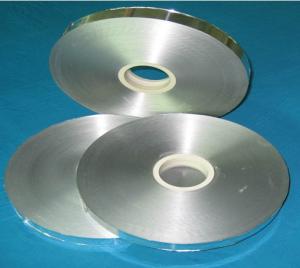

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: The user is asking if they can reuse their old aluminum foil facing to create new ones once it becomes worn out.

- <p>No, you cannot create new aluminum foil facings from old, worn-out ones. Aluminum foil facings are typically made from a specific type of aluminum that is bonded to a substrate. Once it wears out, the aluminum layer is compromised and cannot be reused to make new facings. Recycling old aluminum foil is the best option to reduce waste and conserve resources. You can recycle aluminum foil, which will then be processed and turned into new aluminum products.</p>

- Q: Is it safe to use aluminum foil as a wrapping material for food to be fried?

- <p>Yes, you can use aluminum foil to wrap food and fry it. Aluminum foil is heat resistant and can withstand high temperatures, making it suitable for frying. However, it's important to ensure that the foil is securely wrapped around the food to prevent any oil from seeping in and to avoid any foil from breaking off into the oil, which could be a fire hazard. Always follow safety guidelines when deep frying with aluminum foil to prevent accidents.</p>

- Q: Describe the most effective method for folding aluminum foil edges to seal food packaging.

- <p>The best way to fold aluminum foil facing for food packaging involves a few simple steps. Start by placing the food in the center of the foil. Bring two opposite edges of the foil together over the food, ensuring they overlap slightly. Fold one edge over the other, creating a seam. Press down firmly to seal. Repeat this process with the remaining two edges, ensuring all edges are sealed tightly. For added security, you can fold the edges inward to create a double seam. This method prevents leakage and keeps the food fresh and protected during cooking or storage.</p>

- Q: Is it safe and practical to use aluminum foil with a reflective side to wrap raw meat?

- <p>Yes, you can use aluminum foil facing to wrap raw meat. Aluminum foil is a common and safe material for food packaging, including raw meats. The reflective side of the foil can actually help to keep the meat moist during cooking by reflecting heat. However, it's important to ensure that the foil does not come into direct contact with any open flames as it can cause a fire hazard. Additionally, when using foil for cooking, make sure to poke small holes in it to allow steam to escape, which can help prevent the foil from tearing or the meat from becoming too soggy.</p>

- Q: Is it safe to use the same piece of aluminum foil repeatedly before disposal?

- <p>Reusing aluminum foil is generally not recommended due to hygiene and food safety concerns. Each time you use foil, it can pick up bacteria from food and surfaces, which can multiply with subsequent uses. Additionally, the foil can tear or become thin, potentially allowing harmful substances to leach into your food. For safety, it's best to use a fresh piece of aluminum foil for each use.</p>

- Q: This question asks for a list of various types of aluminum foil facing that can be found in the market.

- <p>There are several types of aluminum foil facing available in the market today, including: 1. Standard Aluminum Foil Facing, which is the most common type used for insulation and moisture protection. 2. Reinforced Aluminum Foil Facing, which is stronger and more durable, often used in high-temperature applications. 3. Embossed Aluminum Foil Facing, which has a textured surface for improved aesthetics and grip. 4. Coated Aluminum Foil Facing, which is coated with materials like polyethylene for added protection against chemicals or moisture. 5. Perforated Aluminum Foil Facing, which has small holes for ventilation or drainage. 6. Laminated Aluminum Foil Facing, which combines aluminum with other materials for enhanced properties. These types cater to various applications in construction, food packaging, and other industries.</p>

- Q: Explain the distinction between aluminum foil insulation with and without a vapor barrier.

- <p>Aluminum foil insulation with a vapor barrier is designed to prevent moisture from passing through, which is crucial in humid environments to prevent condensation and mold growth. The vapor barrier is a layer that acts as a moisture control, enhancing the insulation's effectiveness. On the other hand, aluminum foil without a vapor barrier does not have this moisture-resistant layer, making it less effective in controlling moisture and potentially leading to condensation issues. The presence of a vapor barrier can also impact the thermal performance and energy efficiency of the insulation.</p>

- Q: Is it possible to use aluminum foil with a reflective side to construct a sandwich?

- <p>While it's technically possible to use aluminum foil facing to make a sandwich, it's not recommended. Aluminum foil is not designed for direct food contact, especially the reflective side which may contain harmful substances that could leach into the food. Instead, use the dull side of the foil or better yet, use food-safe wrap or containers for preparing and storing sandwiches.</p>

- Q: Explain the differences between thin and thick aluminum foil facing in terms of thickness, durability, and usage.

- <p>Thin aluminum foil facing is characterized by its low thickness, which makes it flexible and easy to handle but less durable. It's commonly used for wrapping food, baking, and protecting surfaces. Thick aluminum foil facing, on the other hand, is more robust and tear-resistant, suitable for heavy-duty applications such as construction, insulation, and packaging. The thicker material offers better protection and durability, but it's less pliable and can be more challenging to work with.</p>

- Q: Is it possible to recycle aluminum foil with a plastic facing in various countries?

- <p>Recycling practices for aluminum foil with plastic facing vary by country. In some regions, such as parts of Europe and North America, recycling facilities may accept and separate aluminum foil from its plastic lining. However, in other countries, this type of material might not be recyclable due to the difficulty in separating the aluminum from the plastic. It's essential to check local recycling guidelines, as the ability to recycle aluminum foil with plastic facing largely depends on the infrastructure and capabilities of local recycling centers.</p>

Send your message to us

aluminum foil mylar for flexible air duct

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 78 lb/ft

- Supply Capability:

- 7878787 lb/ft/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords