Smoking Meth Aluminum Foil for Industrial Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

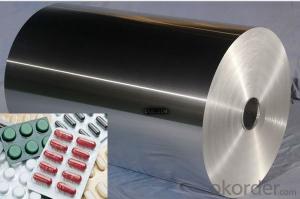

Aluminium Foil For Different Use

1) Structure of Aluminium Foil Description:

This is pure aluminium and is around 0.6 to 2.0 micrometres thick. It is virtually the same material that the BBC used on Coles ribbons, with the exception that they also hand beat the leaf even thinner. They did this by sandwiching the ribbon between toilet paper and beating with a ball-peen hammer.

2)Main features of the Aluminium Foil:

. Flexible and durable

. Light and easy to transport

. Fast delivery

. Item shipped from Dubai warehouse

3) Aluminium Foil Images:

4)PE Composite with Aluminium Foil and Paper Specification:

Aluminum Foil

Alloy type: 8011

Temper: O

Tensile Strength(Mpa): 45-110

Elongation(%): 0.5-16max

Thickness: 0.006mm-0.2mm

Width: 40mm-2000mm

Packing: Aluminum Foil are well packed with export standard suitable for long distance sea transportation.

Use: Mainly used in food packing, electric capacitor, air-conditioner finstock, cable foil, household foil, food container foil, soft packing foil, refrigerator, Pharmaceutical, Industries foil and so on.

Inner diameter: 75mm, 76mm, 150mm, 200mm, 220mm, 300mm, 405mm

outer diameter: 100-1500mm

Payment Term: T/T or L/C at sight

Lead time: about 20-25 days

Kind attention: The specifications can be customized according the customers reques

5)FAQ of PE Composite with Aluminium Foil and Paper:

1. 30% T/T advance , then balance before shipment or against BL copy. Or 30% L/C payment, balanced duaring 30-60 days.

2. The other specific issues can be negociated.

3. Any problem, feel free to contact us. We will reply as soon as possible.

- Q: I got some chicken francese (surrounded in lemon juice) wrapped in one of those tin foil thing with the plastic top restaurants use (mostly italian restaurants) for doggy bagsIt took me twenty minutes to walk home and put it in a dish, is it okay to eat or does eating it risk parkinson/ brain damage?

- kiwi sorbet, my dad used to make it when I was youngerit's goooooood

- Q: I have had this ring for awhile, and hear lately it has been turning my finger greenThe only way I keep it from doing so is, I put clear fingernail poilsh around the insideIs there a way to clean the green off?

- the cheesecake in reality needs to be cooked in a MOIST OVENThat water bath stuff is for the birds! What I have done is put a aluminum pan full of water on the rack directly below the rack that holds your cheesecakeThe oven is moist from the water, and I don't have to have a temper tantrum from having water seep into my cheesecake; and the cheesecake doesn't crack.

- Q: So I made Bu?elos for the first time, my grandma's Recipie and they came out very good (pats myself on the back) anywhoo, after they are finshed and cooled, how do you store them? In an airtight container? I can remember my grandma line a box with aluminum foil, and then putting plastic wrap over themBut, I don't know if that was because she didn't have the means to have Tupperware, in fact I don't think she needed Tupperware her food was so yummy we never had leftovers! I need an answer soon, thanks in advance!

- Go get a relatively frightening novelLike Stephen KingO r my favourite novelist John Saul, believe me you'll get correct absorbed in his novels, boredom shall be a factor of the beyondGood success on that.

- Q: I was wondering what type of metal is on the outside part of a air condenser radiator? Is it aluminum?

- Most a/c condensing coils are made of copper tubes surrounded by aluminum finsSome are all aluminumI get $1.20 per pound for the aluminum/copper kindYou also need an EPA certification number and an evacuation tag to turn them into a scrap yardYou also have to remove the steel bracket on the end to get that price.

- Q: Not sure if they are burner plates or linersFor the 4 burners on top of my stoveSquare shapedThey look like steel but they may be aluminum?? I HAVE NEVER USED THEM ONCEBut I guess cleaning the top of my stove over the years, liquid may have gotten under them, and now there is this rust like stuff that has built up on the bottom and top of them, as well as leaving a stain on the top of the stove surrounding the burnerCurious of any tips and tricks? I purchased some scouring pads, and put a bit of white vinegar, and some baking soda on it, and if I scrub really hard it will lessen, but its a lot of elbow grease neededAnything to help the process along? Again never used themIts not food burns, but I guess liquid that caused the stains over the years from cleaning that seeped under Now I will start using them and want to clean this gunky off themLOL

- Green leafy veggies, cruciferous veggies such as broccoli, brussel sprouts, cabbage, Apples! and tomatoes.

- Q: thank you for your help .

- We had GutterSmith install gutters and guarding a year agoThey did a fantastic jobOne day, great cleanupThe quote was reasonable and accurateAnd the gutters and guards are terrific! They used the KGuard leaf free gutter systemThere are no leaves in the gutters at all, no cleaning, no messALSO, a big plus, if leaves gather or back up, EVER, they will come out and clean them for freeThey are made of .032 Gauge aluminum.

- Q: this is my first time I am buying a grill and dont know what is goodIf we use gas grill tan why cant we use oven in that case and how can it give smokey flavour like in coal grillsI need somethig small and compact and good at the same timeAlso what are combination charcoal grillspl help

- You need to eat high fiber foodsIt aids in digestion as well as keeps you feeling fuller longerBe careful when you first start out eating lots of fiber, to much can give you diarrhea

- Q: DONquot;T waste my time and say quot;i don't smoke potquot; or quot;you shouldn't smoke weedquot;i have been doing weed sense i was in middle school (i just graduated high school).me and my friends were talking and they said they weren't high their fist time.i remember my first time and i was soooooo high i think i started freaking out (but now i'm better with it)so were you high your first time?

- Day or night? Maybe birds have nested thereRaccoons are night folk, that's when they go food seeking.

- Q: Hi everyone,I need to know what I can make out of leftover soft-fried corn tortillasI sometimes fry them for (soft) tacos, but sometimes we have a few leftoverAny recipe ideas for them? Thanks in advance for any ideas you have:)

- My daughter is 15 months and still doesn't use a comforterWe co-sleep and she has her own baby blankets that i cover her withI'm still too afraid to use a big comforter, she moves around way too much and that's just too much blanket for me to feel comfortable withI know she would probably be ok, but i'd rather be safe than sorryFor someone as young as your son, i would not use a comforterYou can buy these sleep bags from Carter's, they are awsome! Swaddling also works wellIf you want to use a blanket, i would use a baby blanket instead of a comforter.

- Q: This farmer had a sick cowThe vet prescribed a daily suppositoryThe farmer's method for administering the prescription was to insert an aluminum tube into the cow's rear and blow the suppository in.One day the farmer was too sick to attend his cow, so he asked his hired hand to take care of the cowThe hired hand took the tube, and turned it around! Then blew the supository into the cowThe farmer's wife, who was standing nearby watching, asked the hired hand why he had turned the tube in the cow's rear around.He exclaimed quot;What! From the farmer's mouth into mine?quot;

- nice one! Check out this joke, Who are the slowest learners in the planet? Convicts, they spend ten years on a single sentence I know its not as funny as yours but, this is the only one good I thought of just know.

Send your message to us

Smoking Meth Aluminum Foil for Industrial Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords