Aluminum Foil Facing Made of by White Polypropylene Film, Fiberglass Scrim and Kraft Paper

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Aluminum Foil Facing

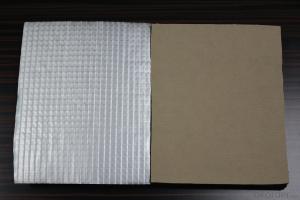

Aluminum Foil Facing is a kind of film, which is made of by Polypropylene 38 microns / Polyethylene / Tri-way fiberglass scrim: 20 x 16/100mm / Kraft paper: 35gsm for Glasswool or Fiberglass Wool Surface Lamination and Insulation

Application of Aluminum Foil Facing

Our aluminum foil facing are mainly used as facing for glass wool insulation, rockwool, mineral wool etc. Also aluminum foil facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter

Advantage of Aluminum Foil Facing

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Packing of Aluminum Foil Facing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Pictures of Aluminum Foil Facing

Specification of Aluminum Foil Facing

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 88 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 110 50 | ASTM D828 |

Burst strength | N | 30 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of Aluminum Foil Facing and is one of the large-scale professional investment Aluminum Foil Facing bases in China. Annually more than 1000 containers of Aluminum Foil Facing are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What are the methods to prevent aluminum foil from shedding into food during cooking?

- <p>To avoid metal flakes from aluminum foil getting into your food, first ensure you're using heavy-duty aluminum foil, which is less likely to tear. Avoid using foil for acidic or highly acidic foods as they can cause the foil to break down. When handling foil, use utensils instead of your hands to prevent oils and salts from your skin causing the foil to flake. Also, do not use foil in broiling or high-heat situations as it can cause the foil to break down and release flakes. Finally, consider using parchment paper or silicone baking mats as alternatives to aluminum foil for certain recipes.</p>

- Q: This question asks about the proper way to store aluminum foil to keep it facing the right way for easy use.

- <p>To store aluminum foil facing the right way, first use up one side completely. Then, fold the remaining foil in half with the shiny side facing out. Place the folded foil back into the box or container, shiny side up. When you need to use it next, the shiny side will be facing you, making it easy to tear off. To keep it flat and wrinkle-free, you can place a piece of cardboard inside the box, or roll it around a clean, empty paper towel tube.</p>

- Q: Is it possible to use aluminum foil with a facing layer to create a pie crust or tart crust?

- <p>Using aluminum foil facing to make a pie crust or tart crust is not recommended. Aluminum foil is not designed for baking and can react with acidic foods, potentially releasing harmful substances. Additionally, it won't provide the same texture or structure as a traditional pie crust. Instead, use materials specifically designed for baking, such as pie dough, tart shells, or parchment paper, which are safe and designed to withstand high temperatures without compromising the taste or quality of your baked goods.</p>

- Q: The user is asking if it's possible to use aluminum foil as a cover for a casserole dish.

- <p>Yes, you can use aluminum foil as a cover for a casserole dish. It's a common practice to cover the dish with foil to prevent the top from drying out during baking or to keep the contents warm. Ensure the foil is food-grade and does not touch the heating elements of the oven. For best results, use heavy-duty aluminum foil to avoid punctures and tearing. Remember to remove the foil during the last few minutes of baking to allow the top to brown if desired.</p>

- Q: Is it possible to recycle aluminum foil facing more than once?

- <p>Aluminum foil facing can be recycled, but it is typically not recycled multiple times due to the thinness and contamination issues. Recycling aluminum involves melting it down, and the thin foil can easily contaminate other aluminum products. Additionally, the foil facing is often laminated with other materials, making it difficult to separate and recycle. While some recycling facilities may accept it, the process is not as efficient as recycling other types of aluminum, and it's often advised to check with local recycling programs for their specific guidelines.</p>

- Q: Is it possible to use aluminum foil facing more than once for various purposes?

- <p>Yes, aluminum foil facing can be reused for multiple purposes. It is commonly reused for cooking, baking, and food storage due to its heat resistance and reflective properties. For instance, you can use it to cover dishes in the oven, line baking sheets, or wrap food for storage. However, it's important to check for any tears or punctures after each use, as these can compromise its effectiveness and potentially lead to椋熷搧瀹夊叏 issues. Additionally, while it can be reused, it's not recommended to use it indefinitely as its performance may degrade over time.</p>

- Q: Describe the process of aluminum foil facing in a few sentences.

- <p>Aluminum foil facing is a process used to laminate aluminum foil to a substrate, typically for decorative or functional purposes. The process begins with the preparation of the substrate, ensuring it is clean and free of contaminants. Then, a layer of adhesive is applied to the substrate. The aluminum foil is then placed onto the adhesive-covered substrate and pressure is applied to ensure proper adhesion. The laminated product is then cured, which can involve heat or UV light to set the adhesive. Finally, the product is trimmed and inspected for quality before being packaged and shipped. This process is used in various industries, including construction, automotive, and consumer goods.</p>

- Q: What are the potential health hazards related to using paper plates in comparison to aluminum foil facing?

- <p>There are generally no significant health risks associated with using paper plates instead of aluminum foil facing. Paper plates are made from food-grade materials and are designed to be safe for contact with food. However, it's important to ensure that the paper plates are free from any harmful chemicals or dyes, and are not contaminated during production or storage. Aluminum foil facing, when used properly, is also safe, but it can leach aluminum into food if heated excessively or used with acidic foods. Both options are generally considered safe, but it's always best to use products from reputable manufacturers and follow usage guidelines.</p>

- Q: Is it possible to use aluminum foil facing as a substitute for a roasting pan?

- <p>While aluminum foil facing can be used in some baking situations, it is not recommended to use it as a direct substitute for a roasting pan. Aluminum foil is not designed to withstand the high temperatures of a roasting process and can melt or warp, leading to uneven cooking and potential safety hazards. A proper roasting pan is made to handle high heat and distribute it evenly, ensuring that your food cooks properly. For best results and safety, use a designated roasting pan or a baking sheet with a higher heat tolerance.</p>

- Q: This question asks for a comparison of the benefits and drawbacks associated with the use of aluminum foil facing in various applications.

- <p>Aluminum foil facing offers several advantages, including excellent heat reflection, which can improve insulation and energy efficiency in buildings. It also provides a moisture barrier, which can protect against water damage and mold growth. Additionally, aluminum foil facing is lightweight, easy to install, and resistant to corrosion. However, there are disadvantages such as its limited strength and durability compared to other materials, making it prone to punctures and tears. It can also be less aesthetically pleasing and may require additional protective layers for long-term use. Furthermore, improper disposal can contribute to environmental concerns due to its non-biodegradable nature.</p>

Send your message to us

Aluminum Foil Facing Made of by White Polypropylene Film, Fiberglass Scrim and Kraft Paper

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords