Aluminum Foil Faced Insulated Rubber Sheet Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Flexible Rubber Plastic Insulation Material Product Description

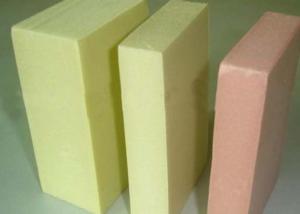

Rubber plastic is a high quality heat-insulating and heat-preservation material which use but yronitrile rubber and polyvinyl chloride(NBR,PVC) as main raw materials. The production process includes mixing, tensing and continuous extruding , heating and foaming.

2.Main Features of Rubber Plastic

-Lower heat-conductivity-Higher fire-blocking performance-Damp-proof and Water-proof-Softness-Neat and -Easy to install easy handing and storage-Good flexibility and tenacity

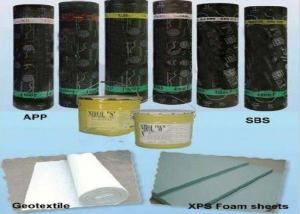

3.Rubber Plastic Images

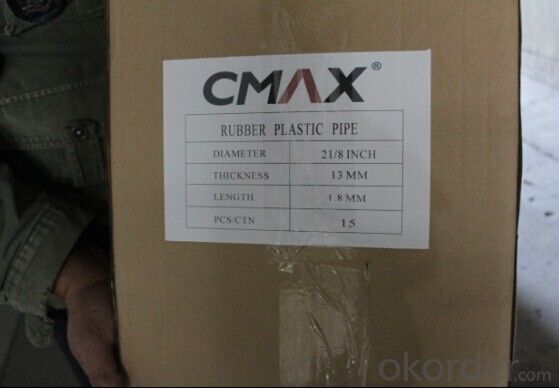

4.Rubber Plastic Specification --Rubber Plastic Sheet

Density(kg/m3) | 40-90 | ||||

Thickness(mm) | 10 mm | 15 mm | 20 mm | 25 mm | 30 mm |

Length (m) | 20 | 20 | 10 | 10 | 10 |

Width (m) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

5.FAQ

①How about your company?A world class manufacturer & supplier of HVAC materials,is one of the large-scale professional investment building materials production bases in China.

②How to guarantee the quality of the products?We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase? In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is it possible to reuse aluminum foil facing after cleaning it?

- <p>Yes, you can reuse aluminum foil facing after washing it, provided it is thoroughly cleaned and dried. Ensure that all residue is removed and it is completely dry to prevent bacterial growth. However, it's important to note that the foil's effectiveness as a barrier may decrease with each use, and it's generally recommended to use a fresh piece for food safety and hygiene, especially when in contact with food.</p>

- Q: Does snow on the roof help or hurt my heating bill?

- Yes, it does. It also shows that you are not losing heat and that you are well insulated.

- Q: This question asks for the steps to prepare aluminum foil for cooking, specifically how to set it up.

- <p>To prepare aluminum foil facing for cooking, first, cut a piece of aluminum foil larger than the cooking surface. Clean the foil to remove any dust or debris. Lightly grease the foil with cooking spray or oil to prevent food from sticking. Fold the edges of the foil up to create a shallow tray, ensuring the sides are high enough to contain any juices. Place the foil on the cooking surface, and you're ready to cook. Always handle the foil with utensils when hot to avoid burns.</p>

- Q: This question asks for the optimal methods of preserving leftover food using aluminum foil.

- <p>The best ways to store leftovers using aluminum foil involve ensuring the food is cool before wrapping, covering the entire dish tightly, and sealing the foil properly. First, let the leftovers cool down to room temperature to prevent condensation. Then, wrap the dish completely with aluminum foil, making sure to cover the edges and corners to avoid air exposure. For added protection, you can double-wrap the dish. Seal the foil by pressing the edges together firmly. Store the wrapped leftovers in the refrigerator or freezer, depending on how soon you plan to consume them.</p>

- Q: What are the methods to prevent food from sticking to the aluminum foil surface during cooking?

- <p>To prevent food from sticking to the surface of aluminum foil when cooking, you can use a few techniques. First, lightly coat the foil with a thin layer of oil or non-stick cooking spray. This creates a barrier that food won't stick to. Second, ensure that the foil is smooth and wrinkle-free; any rough spots can cause food to stick. Additionally, avoid overfilling the foil as this can lead to uneven cooking and sticking. Finally, consider using parchment paper or a silicone baking mat instead of foil for some foods, as they can provide a non-stick surface without the risk of aluminum foil tearing or food sticking.</p>

- Q: Is it safe or practical to use aluminum foil as a facing material for cooking purposes?

- <p>Yes, aluminum foil facing can be used for cooking, but with caution. It's often used to line baking sheets, cover dishes for steaming, or wrap foods for roasting. However, it's not recommended for direct contact with acidic or salty foods as it can react and leach aluminum into the food. Also, avoid using it at high temperatures as it can melt and release harmful fumes. Always follow the manufacturer's guidelines for safe use.</p>

- Q: This question asks about the distinctions among various types of glass fiber paper, which are materials made from thin strands of glass.

- <p>Different types of glass fiber paper are distinguished by their composition, manufacturing processes, and applications. E-glass is the most common and is used for general purposes due to its good electrical insulation properties. S-glass, known for its high strength, is used in applications requiring mechanical strength, such as in aircraft and sports equipment. C-glass is resistant to chemical corrosion and is used in environments with harsh chemicals. A-glass, or alumino-borosilicate glass, is used for applications requiring high temperature resistance. Lastly, D-glass is designed for low dielectric applications, making it suitable for electronics. Each type has unique properties that make it suitable for specific industries and applications.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other types of paper tissues, highlighting their differences.

- <p>Black fiberglass tissue is distinct from other paper tissues due to its composition and properties. It is made from fiberglass, a type of fiber-reinforced plastic, which gives it a unique texture and strength. Unlike traditional paper tissues made from wood pulp, black fiberglass tissue is more durable, resistant to tearing, and less likely to leave lint or shreds. It is often used in industrial applications where high durability and strength are required, such as in gaskets and seals. In contrast, other paper tissues are softer, more absorbent, and designed for everyday use, such as facial tissues or paper towels.</p>

- Q: I added a screened room to my mobile home. I also have vinyl windows. in the summer the sun beats down on the home almost all day Someone told me I could have insulation installed in the roof panels, and that i may even be able to do it myself. Right now it's impossible to enjoy my patio between 1-5pm because it so hot you can't breath. I'm in the Pasco, FL area - 34667Appreciate any help you can give

- Yes you can....you can use metal strapping to hold up 2" foam insualation to the underside of the metal roof that you can get at Home Depot, Lowes, or any hardware store good luck

- Q: What are the potential hazards or dangers of using aluminum foil facing in construction or other applications?

- <p>Using aluminum foil facing can pose certain risks, particularly in construction. It may not provide adequate insulation, leading to energy inefficiency. Additionally, it can trap moisture, causing mold or mildew growth and potential structural damage. Aluminum foil facing can also be a fire hazard if it's not properly installed or if it comes into contact with electrical wiring. Moreover, it may not be as durable as other materials, leading to a shorter lifespan and the need for more frequent replacements. It's crucial to consider these factors and consult with professionals when deciding to use aluminum foil facing in any application.</p>

Send your message to us

Aluminum Foil Faced Insulated Rubber Sheet Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords