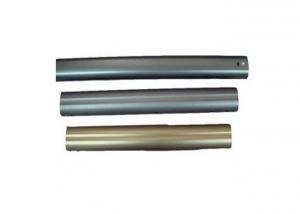

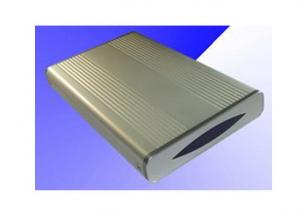

Aluminum Extrusion with Color Anodize Part

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 1000 Pieces per Day pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Detailed Product Description

aluminum milling components

1.Materials:aluminum

2.Process:extrusion

3.High precision

Description:

Material:Aluminum

Surface treatment:color anodize

Process:extrusion

Selling point:

Precision

High quality,ISO9001:2008

Factory direct price and best service

Could customized by any appoint material and specifications

Details for order:

| Processing | CNC Machining, Turning, Milling, Stamping, Die Casting, injection mould,4&5 axis machining | |||||||

| Applicable Material | Aluminum/zinc alloy, iron, steel alloy, plastic, brass, steel, and stainless steel | |||||||

| Surface treatment | polishing,zinc plating,nickel plating,chrome plating,anodizing. | |||||||

| Drawing format | IGS,SLD 2012,X_T,STEP,CAD 2012 and PDF | |||||||

| Annual Capacity: | 200,000pcs | |||||||

| MOQ: | 1-10pcs | |||||||

| Tolerance: | 0.01mm-0.05mm | |||||||

| Lead Time: | 7-10 days(Samples) | |||||||

| QC System: | Select or 100% inspection before shipment. | |||||||

| Payment Terms: | L/C,T/T ,Paypal&Western Union is acceptable. | |||||||

| Packagings: | Standard package/ Pallet or container/As per customized specifications. | |||||||

| Shipment Terms: | express&air freight priority/sea freight/ As per customized specifications. | |||||||

- Q: Is this a standard part, or is it only required to buy the finished products from other factories, or do you want to design and size it yourself?

- According to the specifications of the tools you have used before

- Q: Pull the rifling when rotating or broach tube rotation or both rotation??

- The barrel to fixed wire using rotary broach rifling

- Q: Hope to find a complex tool to do good enterprises, especially broaches do good, quality and Harbin first tool factory and other veteran manufacturers almost or almost no, but the price is relatively cheap, a lot of, thank you

- If the broach requires high accuracy. Find a good factory. If you are producing or looking for cheap private companies, you can use the same price difference.

- Q: Why is the tooth shape of broach oblique?

- Landlord said broach is not a saw, one is mechanical cutting forming processing, a manual cutting, how will the same? Made oblique should be angled in order to make the cutting tooth with the cutting plane, the plane like a razor blade.

- Q: 5.6 small caliber gun rifling production line with much manual broach

- I have a good 5.6 sips of rifling

- Q: Know how to draw Broaches for involute internal spline parameters

- Are you going to pull the spline or external spline spline parameters is of course laane internal spline broach to do;There are many factors in designing broaches, such as machine tool chucks, maximum broaching length, dimension and so on;General to broach company can do, they know how to do, need what parameters will call you to provide

- Q: Ask, what does broach mean?

- Gold series auxiliary skills! Physical and magic attacks can be added!

- Q: Why don't carbon tools steel be used to make Broaches and gear cutters?

- Because of its hardness is too high, easy to crack, and if you do gear cutters and broaches, not only a few times will collapse.Therefore, Broaches and gear cutters must be cemented carbide.The carbon content of carbon tool steel is high, between 0.65-1.35%, and belongs to sub eutectoid, eutectoid or eutectoid steel. The carbon tool steel can get higher hardness and wear resistance after heat treatment, and the core has good toughness. The annealing hardness is low (not more than HB207), and the processing performance is good. However, when the working temperature reached 250 DEG C, the hardness and wear resistance of steel decreased rapidly, the hardness decreased to below HRC60, and the hardenability of this kind of steel was low. Larger tools can not be quenched (water quenched by 15mm), and when water is quenched, the hardness of the surface hardened layer differs greatly from that of the central part. Cause the tool to deform easily when it is quenched. In addition, the range of the quenching temperature is narrow and the temperature should be strictly controlled during quenching. Prevent overheating, decarburization and deformation.

- Q: Machining center spindle broach can not reach the designated position, how to adjust?

- Transfer the nut of the pull rod and remove the main plate

- Q: CNC Lathe Feed base surface is floating, there is no good way to solve?

- A base level is processed in advance

The quality policy is "customer satisfaction". We aim to meet the customers' requirements. With high quality products and competitive price, we have customers in Europe, America, Canada, Australia, Southeast Asia and other countries and regions.This approach of subcontracting offers you technical support in the engineering phase, speed in the prototyping phases, flexibility in the pre-production phase and low piece prices in the volume production phase.

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2012 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America South America Eastern Europe Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen,shenzhen shekou |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Extrusion with Color Anodize Part

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 1000 Pieces per Day pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords