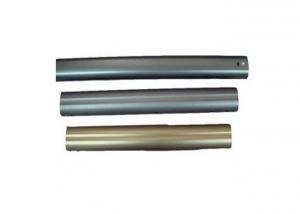

Custom Stainless Steel CNC Turning Metal Working Machining Part

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 3000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Stainless steel machining part

Material:Stainless steel

Process:cnc turning

Inspection:CMM and Projector

Custom machining

Stainless steel cnc turning metal working machining service

Description:

Material:Stainless steel

Surface finish:Smooth

Process:CNC turning

Package:2pcs/Bubble bag,small box and carton,also as your requirement

Advantage:

1,Fine quality

2,Precision

3,Factory direct price

4,Professional

5,On time delivery and good service

A:certification: ISO9001:2008

B.Advantages

1. we are CNC factory with almost 10 years

2. Low MOQ (100pcs is even acceptable in some special conditions)

3. Short lead time (7-30days according to order qty)

4. Customized size and spec /OEM available

- Q: Is this a standard part, or is it only required to buy the finished products from other factories, or do you want to design and size it yourself?

- General milling machine seems to be a root screw, if the NC milling machine is pneumatic or hydraulic broach device. CNC accessories sold, the package should also have, but very expensive. Not interchangeable by different manufacturers. Structurally simple steel ball with broach claws.

- Q: How to solve tooth strain of involute spline broach?

- Workpiece hardness of less than HRC30 is generally broach problem, of course, there are special. It should be cool under normal conditions. I personally do Spline Broach Design and grinding parameters, then the workpiece interested told me to give you the design drawings for reference

- Q: Pull the rifling when rotating or broach tube rotation or both rotation??

- The pipe is fixed and the cutter head can be taken into consideration with the percussion drill at the top of the drill bit, not knowing what exactly. Only know that grinding, and pull a tube, do not rub, do not change the knife!

- Q: Hope to find a complex tool to do good enterprises, especially broaches do good, quality and Harbin first tool factory and other veteran manufacturers almost or almost no, but the price is relatively cheap, a lot of, thank you

- If the broach requires high accuracy. Find a good factory. If you are producing or looking for cheap private companies, you can use the same price difference.

- Q: Why is the tooth shape of broach oblique?

- Because the broaching method of broach is done by layer by layer, the required inner spline shape is eventually machined out. Therefore, the blade of the broach is tilted from front to back

- Q: Know how to draw Broaches for involute internal spline parameters

- Find the formula of involute internal spline on the net, and use 3 point arc instead of involute line. Almost

- Q: I am currently in a lathe machinery factory, factory of broaching machine really curious.It is a hole with the kind of cylindrical broach broaching machine, after a day's work is down to a special knife Seurat with special machine tool grinding.Would you please tell me that the diameter of the broach is not smaller since he repaired it? Wouldn't it be possible to process the required size?

- Hello, this is the general grinding grinding angle in the axial size is 2 off the wire, so allow grinding range or to ensure workpiece size.

- Q: Why don't carbon tools steel be used to make Broaches and gear cutters?

- Because of its hardness is too high, easy to crack, and if you do gear cutters and broaches, not only a few times will collapse.Therefore, Broaches and gear cutters must be cemented carbide.The carbon content of carbon tool steel is high, between 0.65-1.35%, and belongs to sub eutectoid, eutectoid or eutectoid steel. The carbon tool steel can get higher hardness and wear resistance after heat treatment, and the core has good toughness. The annealing hardness is low (not more than HB207), and the processing performance is good. However, when the working temperature reached 250 DEG C, the hardness and wear resistance of steel decreased rapidly, the hardness decreased to below HRC60, and the hardenability of this kind of steel was low. Larger tools can not be quenched (water quenched by 15mm), and when water is quenched, the hardness of the surface hardened layer differs greatly from that of the central part. Cause the tool to deform easily when it is quenched. In addition, the range of the quenching temperature is narrow and the temperature should be strictly controlled during quenching. Prevent overheating, decarburization and deformation.

- Q: Machining center spindle broach can not reach the designated position, how to adjust?

- This is rarely the case. Did you pull the nail in the wrong way?

- Q: CNC Lathe Feed base surface is floating, there is no good way to solve?

- I've been troubled by this problem for a long time. Just as if the needle and double processing, the depth of the top pinhole inconsistency is unable to determine the base. It's impossible for every piece of work to have a knife once,

1. Manufacturer Overview

| Location | Guangdong,China |

| Year Established | 2012 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America South America Eastern Europe Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen,shenzhen shekou |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Custom Stainless Steel CNC Turning Metal Working Machining Part

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Pieces pc

- Supply Capability:

- 3000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords