Malleable Aluminum Strips - Aluminum Expanded Metal Sheet 1050 1100 3003

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Automotive alloys...

(2).Air and gas cylinders...

(3).Aluminium compounds...

3. Feature of Aluminum

Although aluminium is an extremely common and widespread element, the common aluminium minerals are not economic sources of the metal. Almost all metallic aluminium is produced from the ore bauxite

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

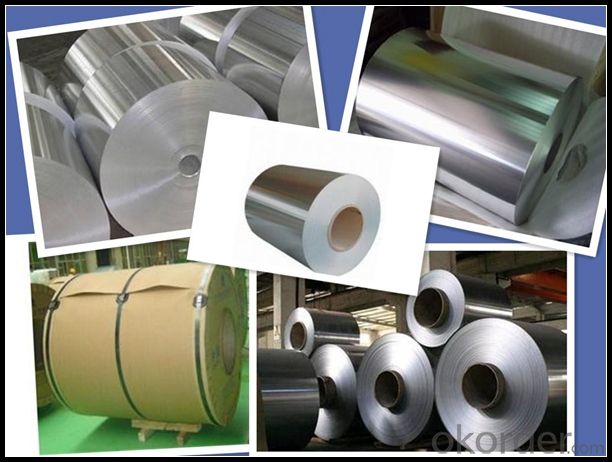

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Is it possible to use aluminum strips for the purpose of covering the interior walls of a building?

- <p>Yes, aluminum strips can be used for interior wall cladding. They are known for their durability, low maintenance, and resistance to moisture and corrosion, making them suitable for various interior applications. Aluminum strips are lightweight, easy to install, and can be used in both residential and commercial settings. They come in various finishes and colors, allowing for customization to match the desired aesthetic. However, it's important to ensure proper installation and adherence to building codes and safety standards.</p>

- Q: This question asks for a step-by-step guide on how to attach aluminum strips to a roof, likely for decorative or protective purposes.

- <p>To install aluminum strips on a roof, follow these steps: 1. Clean the roof area where the strips will be installed to ensure a good adhesive bond. 2. Measure and cut the aluminum strips to the required length. 3. Apply a high-quality construction adhesive or sealant along the back of the aluminum strips. 4. Carefully position the strips onto the roof, pressing firmly to ensure proper adhesion. 5. Use a level to ensure the strips are straight and aligned. 6. Allow the adhesive to cure according to the manufacturer's instructions. 7. Seal any gaps or joints between the strips with additional sealant if necessary. 8. Inspect the installation to ensure all strips are securely in place. Safety precautions such as using a ladder and wearing protective gear should be observed throughout the process.</p>

- Q: This question asks for the various types of insulation materials that are created using aluminum strips.

- <p>Aluminum strips are used in the production of several types of insulation materials. One common type is reflective insulation, which uses aluminum's reflective properties to reduce heat transfer. This can be found in the form of foil insulation or radiant barrier insulation. Another type is aluminum foil-backed insulation, often used in HVAC systems to prevent heat loss. Additionally, aluminum is a component in some types of flexible duct insulation, providing both thermal and acoustic insulation. Lastly, aluminum is used in certain types of thermal insulation boards, which are used in construction to provide thermal resistance. These materials are valued for their durability, resistance to corrosion, and effectiveness in thermal management.</p>

- Q: What other materials could potentially be used in place of aluminum strips for specific uses?

- <p>Yes, there are alternative materials that can replace aluminum strips in certain applications. These include stainless steel, which offers high strength and corrosion resistance; copper, known for its excellent electrical conductivity; magnesium alloys, which are lightweight and have good thermal conductivity; and titanium, prized for its strength and resistance to corrosion. The choice of material depends on the specific requirements of the application, such as strength, weight, cost, and environmental factors.</p>

- Q: What are the various types of waterproofing materials that utilize aluminum strips in their composition?

- <p>Aluminum strips are used in several types of waterproofing materials due to their durability and resistance to corrosion. Some common types include: 1) Aluminum Foil Tapes: These are adhesive tapes with an aluminum foil backing, used for sealing joints and seams. 2) Aluminum Coated Fabrics: Fabrics coated with aluminum to provide a barrier against water and UV rays, often used in construction and roofing. 3) Aluminum Flashing: Sheets of aluminum used to cover joints and intersections in roofing and walls to prevent water infiltration. 4) Aluminum Waterproofing Membranes: These are flexible sheets that can be applied to surfaces to create a waterproof barrier. 5) Aluminum Coated Self-Adhesive Sheets: These are sheets with a self-adhesive backing and an aluminum coating, used for sealing and waterproofing applications. Each type serves specific waterproofing needs and is chosen based on the application and environmental conditions.</p>

- Q: What types of aluminum alloys are known for their higher resistance to corrosion compared to other aluminum types?

- <p>Yes, certain types of aluminum alloys exhibit greater resistance to corrosion. These include 3003, 5052, and 5083 aluminum alloys, which contain magnesium and manganese, enhancing their corrosion resistance. Additionally, 6061 aluminum, which contains magnesium and silicon, is known for its good resistance to atmospheric corrosion. These alloys are often used in marine environments and other corrosive conditions due to their superior corrosion resistance.</p>

- Q: Is it appropriate to use aluminum strips for constructing outdoor furniture?

- <p>Yes, you can use aluminum strips for outdoor furniture. Aluminum is a popular choice due to its durability, resistance to corrosion, and low maintenance requirements. It doesn't rust and can withstand various weather conditions, making it suitable for outdoor use. However, ensure that the aluminum is of high quality and treated to resist UV rays and other environmental factors to prolong its lifespan and maintain its appearance.</p>

- Q: What are the certifications or standards that apply to aluminum strips?

- <p>Yes, there are several certifications and standards for aluminum strips. These include ASTM B209, which specifies requirements for aluminum and aluminum alloy sheet and plate, and EN 573, which covers the chemical composition and mechanical properties of aluminum and aluminum alloys. Additionally, there are ISO standards such as ISO 6361 and ISO 6892 that define the requirements for aluminum and aluminum alloys in terms of mechanical properties and chemical composition. These standards ensure the quality and consistency of aluminum strips used in various industries.</p>

- Q: Explain the use of aluminum strips in the automotive industry briefly.

- <p>Aluminum strips are widely used in the automotive industry due to their lightweight, corrosion resistance, and high strength-to-weight ratio. They are commonly used in the manufacturing of car bodies, engine parts, and heat exchangers. Aluminum strips are also utilized in the production of wheels, where their lightweight nature contributes to improved fuel efficiency and performance. Additionally, they are employed in the construction of radiators, air conditioning systems, and various electrical components due to their excellent thermal conductivity and electrical properties. The use of aluminum strips in automotive applications helps reduce vehicle weight, which in turn enhances fuel economy and reduces emissions.</p>

- Q: Describe the steps involved in the manufacturing process of aluminum strips.

- <p>The process for manufacturing aluminum strips involves several key steps. Initially, aluminum ingots are melted in a furnace, often using a direct current furnace for better control over the melting process. The molten aluminum is then poured into molds to create a cast billet. This billet is then heated and passed through a series of rolling mills to reduce its thickness and achieve the desired strip dimensions. During rolling, the aluminum is continuously cooled to control its temperature and maintain its mechanical properties. After rolling, the aluminum strip may undergo additional processes such as annealing to improve ductility or coating to provide a protective layer. Finally, the strip is cut to length, inspected for quality, and packaged for distribution.</p>

Send your message to us

Malleable Aluminum Strips - Aluminum Expanded Metal Sheet 1050 1100 3003

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords