Aluminum Color Coil Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

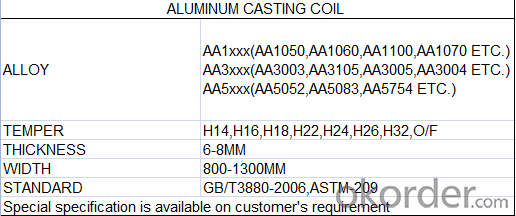

1.Structure of Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. The thickness of Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

4. Production Process of Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: How do aluminum coils contribute to energy-efficient windows and doors?

- The significance of aluminum coils in enhancing the energy efficiency of windows and doors cannot be overstated. To begin with, aluminum, being a highly conductive material, possesses the ability to efficiently transfer heat and cold. This characteristic enables aluminum coils to act as effective thermal barriers, preventing the exchange of heat from the exterior to the interior and vice versa. By reducing heat transfer, aluminum coils assist in minimizing the energy required for cooling or heating a structure, resulting in decreased energy consumption and lower utility bills. In addition, the lightweight and durable nature of aluminum coils makes them a preferred choice in the construction of window and door frames. Their lightweight attribute facilitates easier installation and operation of windows and doors, while their durability ensures long-lasting performance. Furthermore, the usage of aluminum coils permits the creation of sleek and narrow frame designs, optimizing the amount of glass area and allowing ample natural light to enter the building. This reduces the reliance on artificial lighting during daylight hours, further contributing to energy savings. Furthermore, aluminum is a highly recyclable material, and the utilization of aluminum coils promotes sustainability. By incorporating recycled aluminum in the manufacturing of these coils, energy-efficient windows and doors can be produced with a significantly lower carbon footprint. This aids in minimizing the environmental impact of the construction industry and contributes to a more sustainable future. In conclusion, the thermal barrier properties, lightweight and durable nature, as well as the recyclability of aluminum coils, make them indispensable in the creation of energy-efficient windows and doors. By reducing heat transfer, facilitating efficient installation, and decreasing the reliance on artificial lighting, aluminum coils play a vital role in the development of sustainable and energy-saving building solutions.

- Q: This question seeks to understand the environmental impact of discarded aluminum coils.

- <p>Discarded aluminum coils can have significant environmental impacts. They contribute to landfill waste and can potentially leach harmful substances into the soil and water if not properly managed. Aluminum production is energy-intensive, so recycling discarded coils reduces the demand for raw materials and conserves energy. However, if left in the environment, aluminum can also contribute to pollution and disrupt ecosystems. Proper recycling and disposal methods are crucial to mitigate these effects and promote sustainability.</p>

- Q: What are the different coil packaging sizes available for aluminum coils?

- The customer's specific needs and requirements determine the available packaging sizes for aluminum coils. However, standard coil packaging sizes are generally found in the market. These sizes vary in dimensions and weights, ranging from small to large. Various common coil packaging sizes for aluminum coils include: 1. Small coils: These serve smaller applications or projects and typically have a diameter of 200-300mm and a weight of 50-150kg. 2. Medium coils: Suitable for medium-sized applications and projects, these coils usually have a diameter of 300-600mm and a weight of 150-500kg. 3. Large coils: Designed for larger applications or projects requiring a substantial amount of aluminum, these coils typically have a diameter of 600-1200mm and a weight of 500-2000kg. It's important to note that these are general guidelines, and the actual coil packaging sizes may vary depending on the manufacturer and specific customer requirements. Moreover, unique project needs often allow for the request of custom packaging sizes.

- Q: What are the best rust-proof coils? Please tell me the model and manufacturer in Shangdong. Thank you.

- 3003 aluminum coil, AL-Mn series alloy, is the most widely used rust-proof aluminum with the density being 2.73. It is applicable to insulation projects such as pipe insulation, packaging, machine parts, refrigerator, air conditioning and ventilation pipes and other wet environment.

- Q: Hi, I have a large bag of aluminium sulfate that I would like to use to turn my hydrangeas blue but there are no instructions on the pack, can anyone tell me how much I need (mixed with water)

- I usually sprinkle about 1/4 cup around the base of the plant and water it in. This must be done before flowers appear.

- Q: Are aluminum coils suitable for air conditioning systems?

- Yes, aluminum coils are suitable for air conditioning systems. Aluminum coils offer excellent heat transfer properties, durability, and resistance to corrosion, making them a popular choice in air conditioning systems. They are lightweight, efficient, and can withstand high-pressure applications, making them a reliable option for cooling and refrigeration purposes.

- Q: What are the methods to prevent rust formation on steel coils during storage and transportation?

- <p>To prevent rust on steel coils during storage and transportation, follow these steps: 1. Keep the coils dry and avoid exposure to moisture. 2. Use rust inhibitors or anti-corrosion coatings on the coils. 3. Store the coils in a clean, dry, and well-ventilated area. 4. Use protective wrapping materials like plastic film or corrosion-resistant paper. 5. Ensure proper stacking and avoid direct contact between coils. 6. Use rust-resistant materials for transportation containers. 7. Regularly inspect the coils for signs of rust and address any issues promptly. By implementing these measures, you can significantly reduce the risk of rust formation on steel coils.</p>

- Q: Relevant question 5Excuse me, what's the meaning of your "deoiling effect"? And you answer two kinds of performance, my understanding is that the oil removal effect is not good, lead to aluminum volume is not neat, what is the difference between the two? Solution, thank you

- I think the 0.14mm is certainly not the aluminum coil lining sleeve forgot, then the biggest doubt is the oil removal effect is not good, with rolling after the aluminum layer between the leakage for aluminium roll support is not enough, the collapse of the volume, the specific performance is the edge of the circular aluminum layer was uniform into ripples; in addition is a kind of expression is down when the aluminum coil suddenly becomes uneven, but the bad effect caused by oil

- Q: Aluminum coil area, with aluminum sheet area, how is not the same?

- Direct measurement length and width calculation area of aluminium plate;The aluminum coil can measure the volume of the aluminum coil and then calculate the area by dividing the thickness. You can also measure the mean diameter, calculate the perimeter, multiply the number of laps, the width, and calculate the area.

- Q: Are aluminum coils suitable for pharmaceutical vial caps?

- Yes, aluminum coils are suitable for pharmaceutical vial caps. Aluminum is a commonly used material in the pharmaceutical industry due to its excellent barrier properties, corrosion resistance, and ability to be easily sterilized. It provides a tight seal, ensuring the integrity and safety of the vial contents. Additionally, aluminum coils can be easily formed into the desired shape and size for vial caps, making them a reliable choice for pharmaceutical packaging.

Send your message to us

Aluminum Color Coil Aluminum Cast Roll for Manufacture of Aluminum Coils and Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords