China Pe Coated Aluminum Coil Stock for Aluminum Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Coil Stock used for Aluminum Foil

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Aluminum Coil Stock used for Aluminum Foil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Coil Stock used for Aluminum Foil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

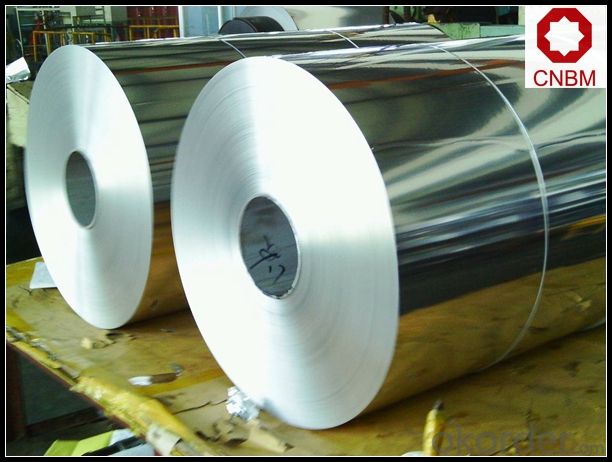

5. Image of Aluminum Coil Stock used for Aluminum Foil

6. Package and shipping of Aluminum Coil Stock used for Aluminum Foil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ of

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils suitable for architectural louvers?

- Indeed, architectural louvers can be constructed using aluminum coils as they possess remarkable corrosion resistance, a lightweight composition, and a commendable strength-to-weight ratio. The malleability and manipulability of aluminum coils grant them the ability to be effortlessly shaped and fabricated into diverse forms and dimensions, thereby rendering them exceptionally suitable for fashioning aesthetically appealing and practical louvers. Moreover, the robustness of aluminum guarantees that the louvers will endure severe weather conditions and retain their structural integrity for an extended period. In conclusion, aluminum coils serve as a dependable and adaptable material choice for architectural louvers.

- Q: Can aluminum coils be welded?

- Absolutely! Welding aluminum coils is indeed possible. Aluminum is a material known for its exceptional weldability and is widely utilized in various industries because of its lightweight nature and resistance to corrosion. There are numerous welding techniques available for joining aluminum coils, including TIG welding (tungsten inert gas), MIG welding (metal inert gas), and even laser welding. Nevertheless, it is crucial to bear in mind that welding aluminum can be more demanding compared to other metals due to its high thermal conductivity and low melting point. As a result, it is imperative to employ appropriate welding methods and equipment, such as specialized aluminum welding wire and shielding gases, to guarantee successful and top-notch welds.

- Q: What are the common recycling methods for aluminum coils?

- Aluminum coils can be recycled using various methods. Mechanical recycling is a commonly employed technique. It entails shredding the coils into small pieces and then melting them to create new coils. This method is both efficient and cost-effective, as it maintains the quality of the aluminum material while allowing for its reuse. Pyrolysis is another method used for aluminum coil recycling. It involves heating the coils at high temperatures in the absence of oxygen. This process breaks down the aluminum into its constituent elements, enabling the recovery of valuable metals and other byproducts. Chemical recycling is an alternative approach for recycling aluminum coils. It involves dissolving the coils in a chemical solution to separate the aluminum from other materials. The resulting aluminum can then be utilized to manufacture new coils. Lastly, smelting is a method that can be employed for aluminum coil recycling. It revolves around melting the coils and separating impurities through electrolysis. This method facilitates the recovery of pure aluminum, which can be utilized in the production of new coils. In summary, these recycling methods play a pivotal role in reducing the environmental impact of aluminum coil production. They conserve resources, minimize waste, and promote the sustainability of the aluminum industry by encouraging the reuse of materials and decreasing the need for new aluminum production.

- Q: What are the different packaging options for aluminum coils?

- There are various packaging options available for aluminum coils to ensure their safety and convenience during transportation and storage. Some common packaging options include: 1. Wooden Crates: Aluminum coils are often packaged in wooden crates, which provide excellent protection against impacts and ensure the coils remain intact during transit. The crates are typically reinforced with steel bands for added strength and stability. 2. Cardboard Boxes: Smaller aluminum coils or coils intended for retail purposes are often packaged in cardboard boxes. These boxes are lightweight, cost-effective, and provide moderate protection against minor impacts. 3. Plastic Wrapping: Aluminum coils can also be wrapped in plastic film, which helps protect them from moisture, dust, and scratches. This packaging option is commonly used for coils that are transported in bulk or in situations where additional packaging is not required. 4. Metal or Composite Tubes: In some cases, aluminum coils are packaged in metal or composite tubes. These tubes are sturdy and provide excellent protection against external forces. They are often used for coils with large diameters or longer lengths. 5. Customized Packaging: Depending on the specific requirements of the customer or industry, customized packaging options can be designed. This may include the use of foam or cushioning materials to provide additional protection, or the incorporation of specialized features such as moisture-resistant barriers. It is important to choose packaging options that best suit the specific needs of the aluminum coils, considering factors such as coil size, weight, transportation conditions, and storage requirements.

- Q: What is the typical coefficient of thermal expansion for aluminum coils?

- Aluminum coils usually have a coefficient of thermal expansion around 23 x 10^-6 per degree Celsius. This implies that with each degree Celsius rise in temperature, the length of the aluminum coil will expand by 23 parts per million. The coefficient of thermal expansion holds significance in the design and handling of aluminum coils, as it impacts their dimensional stability and can induce thermal strains in the material due to temperature fluctuations.

- Q: Can aluminum coils be used in automotive manufacturing?

- Automotive manufacturing can indeed utilize aluminum coils. Aluminum, a versatile and lightweight substance, presents several advantages within the automotive sector. Frequently employed for fabricating components such as body panels, engine blocks, wheels, and heat exchangers, aluminum's incorporation in automotive manufacturing enhances fuel efficiency by reducing vehicle weight and subsequently minimizing energy consumption. Furthermore, aluminum boasts exceptional resistance to corrosion, rendering it appropriate for deployment in diverse weather conditions. In conclusion, the extensive benefits associated with the utilization of aluminum coils in automotive manufacturing have led to its widespread adoption by numerous car manufacturers.

- Q: The export of aluminum coil, according to steel coil declaration, will there be any problems?

- If you have already declared itCheck the corresponding HS code, to import countries taxes and fees are the same, whether the customer side mind?.China's tax rebate rate, you also see what kind of high?.In addition to export will have a steel coil sampling, aluminum volume difference is relatively large, so if the declaration, to take note of this, if the sampling try with conversational communication forwarding, otherwise it would be a big problem.

- Q: The user is asking if it's possible to recycle old aluminum coils to create new ones.

- <p>Yes, you can recycle old aluminum coils into new ones. Recycling aluminum is a highly efficient process, and it's very common in the industry. Aluminum has one of the highest recycling rates among metals due to its value and the energy savings associated with recycling compared to producing new aluminum from raw materials. When you recycle aluminum, it can be melted down and reformed into new coils or other products without losing its properties. This process helps conserve resources and reduces environmental impact.</p>

- Q: Calculate the specific heat of aluminum (in calories).mass of aluminum25.0 gmass of water23.2ginitial temperature of aluminum98.0Cinitial temperature of water20.0Cfinal temperature of water33.0Cround to three decimal places, do not include units.

- Heat gained by water = heat lost by aluminum Heat = H mass = m specific heat =c change in temperature = dT H = mcdT mcdT for water = mcdT for Al (23.2)(1.00)(13) = (25.0)(c(Al))(33-98) c(Al) = (23.2)(1.00)(13)/(25.0)(65) = 0.186 This value is just a bit below the known value of specific heat for aluminum, where c = 0.217 cal/g.C

- Q: What are the methods to prevent rust formation on aluminum coils during storage and transportation?

- <p>To prevent rust on aluminum coils during storage and transportation, ensure that the coils are clean and dry before storage. Store them in a cool, dry place away from moisture and corrosive substances. Use protective wrappings or coatings to shield the coils from the environment. Maintain proper ventilation to reduce humidity. Avoid stacking the coils directly on the ground; use pallets or racks to keep them off damp surfaces. Regularly inspect the coils for signs of moisture or damage and address any issues promptly.</p>

Send your message to us

China Pe Coated Aluminum Coil Stock for Aluminum Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords