Aluminum Coil Price for 1050 Temper Aluminium Coil with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Aluminium Coil

5000 series aluminium alloy sheet: 1050 aluminium alloy sheet are representative in the 5000 series of aluminium sheet. The 5000 series aluminium sheet is the more commonly used aluminum alloy sheet series, the main elements is magnesium, also it can be called Al-Mg alloy. The 5000 series aluminium alloy sheet main feature is low density, high tensile strength, high elongation, etc. In the same area under the weight of aluminum-magnesium alloy is lower than other series, so the 5000 series aluminium alloy sheet is often used in aviation, and it are also widely used in the conventional industry.

Alloy | Thickness(mm) | Width(mm) | Length(mm) | Temper | DC or CC | |

1050,1060,1070,1100, 1235 | 0.2-3.0 | 300-1850 | 1000-8000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

3.0-150 | 900-1900 | H112,H111 | DC | |||

3003,3004,3105,3005 | 0.2-3.0 | 300-1850 | 1000-8000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

3.0-150 | 900-1900 | H112,H111 | DC | |||

5052,5083,5754,5005 | 0.2-3.0 | 300-1850 | 1000-8000 | O,H12,H22,H14,H24,H16,H26,H18,H32,H36 | DC | |

3.0-150 | 900-1900 | H112, H111 | DC | |||

6061,6063 | 0.5-3.0 | 300-1500 | 1000-6000 | T6,T321 | DC, | |

The Main Features of Aluminium Coil:

High quality with competive prices.

Wide product range of choice.

We are specific manufacture and control.

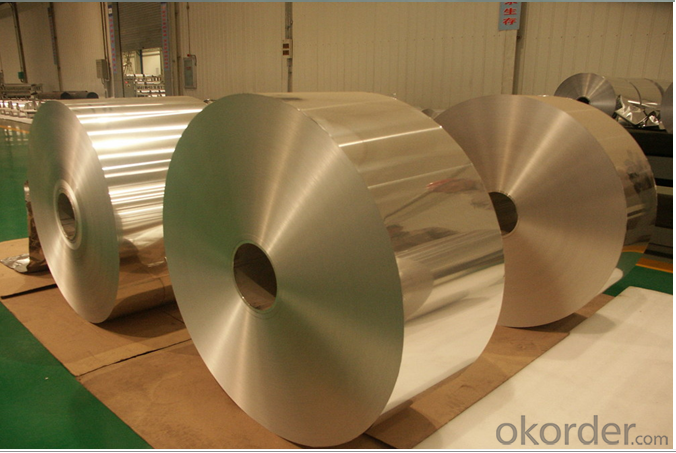

The Images of Aluminium Coil:

FAQ:

1. Minimum Order Quantity? MOQ is 25 tons, your quantity is ok, the aluminium foil sample is available. |

2. What kind of terms of payment? T/T, L/C,D/A,D/P,Western Union are available. |

3. What grams of the product can you offer? Our products can be customized according to your requirment |

4.Can you do Customization & Reproduction if I provide a photo? Yes, we do Customization & Reproduction service, please check the details and sample above. You need to send the pictures to our email, tell us the specification you want, then we will quote you exact price. We will take photos for you check. |

5. Does the packaging safe and arrive in good conditions? Yes, Safe Packing guarrantee, all the products will arrive your door under good conditions. We response to problem of shipping if there unfortunately is. |

6. How long does it usually take to deliver the product? We'll make the shipment to you immediately. It will take about 18 to 40 days arrive worldwide. Accurate delivery time depends on the specific quantity |

7.Is drop shipping abailable? Yes, it is, we can send to worldwide. |

- Q: What are the potential applications of laminated aluminum coils?

- Laminated aluminum coils have a wide range of potential applications. They can be used in industries such as electrical, automotive, aerospace, and construction. Some specific applications include electrical transformers, heat exchangers, automotive radiators, air conditioning systems, and architectural facades. The lamination process enhances the durability, heat and corrosion resistance, and electrical conductivity of the coils, making them suitable for various demanding environments and applications.

- Q: What are the common surface protection methods for aluminum coils?

- The common surface protection methods for aluminum coils include anodizing, painting, and coating with protective films or laminates.

- Q: How are aluminum coils used in the production of heat exchangers?

- Aluminum coils play a crucial role in the production of heat exchangers. Heat exchangers are devices used to transfer heat between two or more fluids, allowing for efficient heating or cooling in various applications. The use of aluminum coils in heat exchanger production is primarily due to the unique properties of aluminum. Firstly, aluminum is an excellent conductor of heat. It possesses a high thermal conductivity, which means it can efficiently transfer heat from one fluid to another. This property is particularly important in heat exchangers, as it ensures that the heat exchange process is rapid and efficient. Secondly, aluminum is lightweight and has a high strength-to-weight ratio. This makes it an ideal choice for heat exchangers, as it allows for the production of compact and lightweight units that can be easily installed in various systems. The lightweight nature of aluminum coils also reduces the overall weight of the heat exchanger, which can be advantageous in applications where weight is a concern, such as automotive or aerospace industries. Additionally, aluminum coils have excellent corrosion resistance. Aluminum naturally forms a thin oxide layer on its surface, which protects it from corrosion. This resistance to corrosion is vital in heat exchangers, as they often come into contact with different fluids that may be corrosive. The use of aluminum coils ensures the longevity and durability of the heat exchanger, preventing premature failure or damage. Moreover, aluminum coils are highly malleable and can be easily formed into different shapes and sizes. This flexibility in manufacturing allows for the production of customized heat exchangers that can be tailored to specific applications and requirements. The ability to shape aluminum coils also facilitates the design of complex heat exchanger geometries, maximizing the heat transfer surface area and enhancing overall performance. In summary, aluminum coils are extensively used in the production of heat exchangers due to their high thermal conductivity, lightweight nature, corrosion resistance, and malleability. These properties make aluminum an ideal material for efficient heat transfer, compact designs, durability, and customization. Overall, aluminum coils contribute significantly to the effectiveness and reliability of heat exchangers in various industries and applications.

- Q: What are the potential challenges in recycling aluminum coils?

- There are several potential challenges in recycling aluminum coils. Firstly, aluminum coils often contain contaminants such as paint, oil, or other coatings that need to be removed before the recycling process can take place. This can be a time-consuming and costly process, as the coils need to be thoroughly cleaned to ensure the quality of the recycled aluminum. Secondly, aluminum coils are often mixed with other materials such as steel or plastic, which further complicates the recycling process. These materials need to be separated from the aluminum before it can be melted down and recycled. This separation process requires specialized equipment and expertise, adding to the overall cost and complexity of recycling aluminum coils. Another challenge is the transportation and logistics involved in recycling aluminum coils. These coils are often large and heavy, making it difficult and expensive to transport them to recycling facilities. Additionally, the recycling facilities themselves need to have the necessary infrastructure to handle and process these coils efficiently. Moreover, the fluctuating market prices of aluminum can also pose a challenge in recycling aluminum coils. The value of recycled aluminum is influenced by factors such as global supply and demand, which can vary significantly over time. This can make it difficult for recyclers to accurately predict the financial returns from recycling aluminum coils, potentially affecting the viability of the recycling process. Lastly, the overall awareness and participation in aluminum coil recycling can be a challenge. Many industries or individuals may not be aware of the benefits of recycling aluminum coils or may not have access to recycling facilities. Increasing education and accessibility to recycling programs can help overcome this challenge and promote the sustainable recycling of aluminum coils.

- Q: Can aluminum coils be used in high-pressure or high-temperature environments?

- Aluminum coils are not typically recommended for use in high-pressure or high-temperature environments. While aluminum is known for its high thermal conductivity and corrosion resistance, it has certain limitations when exposed to extreme conditions. In terms of high-pressure environments, aluminum coils may not possess the necessary strength and durability required to withstand the forces exerted by the pressurized system. Aluminum has a lower tensile strength compared to other metals like steel or titanium, which makes it more prone to deformation or failure under high pressure. Therefore, it is generally advised to use materials with higher strength and pressure ratings in such scenarios. Similarly, aluminum coils have a relatively low melting point compared to metals like steel or copper. The melting point of aluminum is around 660 degrees Celsius (1220 degrees Fahrenheit), which makes it susceptible to damage or failure in high-temperature environments. In applications where the temperature exceeds the melting point of aluminum, it is recommended to use materials with higher temperature resistance. However, it is worth mentioning that there are specialized alloys and coatings available that can enhance the high-temperature and high-pressure capabilities of aluminum. These modifications can improve its strength, heat resistance, and corrosion resistance, making it suitable for certain applications in extreme conditions. Nonetheless, the specific requirements and limitations of the intended environment should be carefully considered before deciding to use aluminum coils. Consulting with experts and considering alternative materials may be necessary to ensure the safety and efficiency of the system.

- Q: The user is asking if it's possible to use an electric welder for joining aluminum coils.

- <p>Yes, you can use an electric welder to weld aluminum coils together. However, it's important to use the correct type of welder and settings. Gas tungsten arc welding (GTAW), also known as TIG welding, is commonly used for aluminum due to its precision and ability to control heat input. MIG (Metal Inert Gas) welding can also be used for thicker aluminum materials. Ensure you use the right filler material, a suitable welding current, and proper shielding gas to prevent oxidation. Always follow safety precautions and consult with a professional if you're unsure about the welding process.</p>

- Q: What is the typical thickness tolerance for aluminum coils?

- The thickness tolerance for aluminum coils can vary based on specific requirements and industry standards. Generally, the tolerance falls within a range of +/- 0.002 to 0.005 inches. This means that the actual thickness of the aluminum coil can deviate from the specified thickness by a maximum of either 0.002 or 0.005 inches, depending on the tolerance requirements. It's worth noting that these tolerances can also be expressed as a percentage of the specified thickness, typically ranging from 4% to 8%. These tolerances ensure that the aluminum coil thickness aligns with desired specifications and allows for an acceptable level of variation for the intended application.

- Q: Are there any restrictions on the export or import of aluminum coils?

- The export or import of aluminum coils is subject to restrictions that vary depending on the country and specific regulations in place. These restrictions encompass various measures such as export licenses, quotas, and tariffs. Export licenses are often necessary to comply with export control regulations, particularly for sensitive industries or countries. Quotas restrict the quantity of aluminum coils that can be exported or imported within a specific timeframe. Tariffs, on the other hand, involve taxes imposed on imported goods, impacting the cost and competitiveness of aluminum coils in the market. Furthermore, additional restrictions may be imposed concerning quality standards, environmental regulations, or trade agreements between countries. Therefore, it is crucial for individuals or businesses engaged in the export or import of aluminum coils to conduct thorough research and gain a comprehensive understanding of the specific restrictions within their respective jurisdictions. Seeking guidance from legal or trade experts can facilitate navigation through these restrictions and ensure compliance with applicable laws.

- Q: Describe the manufacturing steps involved in producing aluminum coils.

- <p>The production processes of aluminum coils involve several key steps. Initially, aluminum ingots are melted in a furnace. The molten aluminum is then transferred to a casting machine where it is cast into a continuous strip. This strip is cooled and passed through a series of rollers to reduce its thickness and achieve the desired coil gauge. The rolling process can be hot or cold, depending on the final product's properties. After rolling, the aluminum coil may undergo annealing to improve its ductility and strength. It is then cleaned, oiled, and wound into coils. Quality control checks are performed throughout the process to ensure the coils meet specific standards. Finally, the aluminum coils are packaged and shipped for various applications such as construction, automotive, and packaging industries.</p>

- Q: How do aluminum coils compare to plastic coils in terms of durability?

- Aluminum coils generally offer superior durability compared to plastic coils. Aluminum is a highly durable material known for its strength and resistance to wear and tear. It can withstand heavy usage and is less likely to crack, break, or deform under pressure. On the other hand, plastic coils may be more prone to damage, especially when subjected to repetitive use or extreme temperatures. While plastic coils can be cost-effective and lightweight, they may not hold up as well over time. Therefore, if durability is a priority, aluminum coils are a better choice as they offer a longer lifespan and greater resistance to damage.

Send your message to us

Aluminum Coil Price for 1050 Temper Aluminium Coil with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords