0270a00983 Aluminum Coil - Aluminum Coated Strips for Ring-Pull 5182 H48

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Coated Strips Used for Ring-Pull 5182 H48

We professionally produce aluminium coated strips used for can tabs or ring-pulls. During production, we use large wave shear, transverse shear and longitudinal cut system so as to meet different specifications of customers.

Based on ordinary aluminum, we add Mn and Mg, so as to increase tensile strength and elongation. Normally we use 5182, H48 for production.

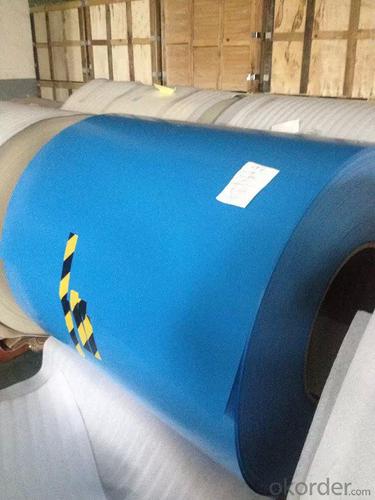

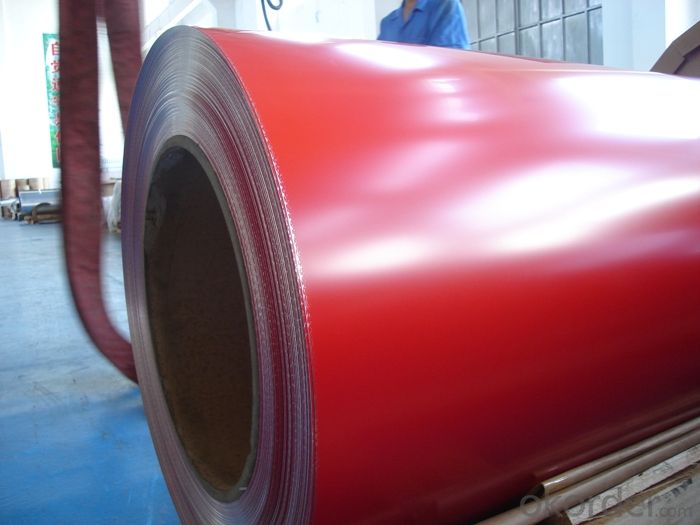

Our coated aluminum strips for tabs are colorful and glossy. We have different colors for tabs, such as blue, red, transparent, etc. We also can adjust coating according to color of customers and offer personalized services.

2. Main Features of Aluminum Coated Strips Used for Ring-Pull 5182 H48

• Light Weight

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rustproof

3. Aluminum Coated Strips Used for Ring-Pull 5182 H48 Images

4. Specification of Aluminum Coated Strips Used for Ring-Pull 5182 H48

ALLOY | TEMPER | THICKNESS | WIDTH | COIL OR LENGTH |

5052 5182 | H19 H36 H48 H49 | 0.22-0.5mm | 500-1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: is there any kind of solder or technique that can solder copper to aluminium? or is it just not possible!?

- Yikes, this post is chock full of misleading information. Of course it's possible. How do I know? I do it 6-8 hours a day. Lead/tin and tin/copper solders bond to aluminum very well, they just don't bond to aluminum oxide. This soldering can be done by exposing fresh aluminum through scoring, scraping or sanding, then quickly soldering. Or use a purge box like we do - exclusion of oxygen solves the issue nicely, but an initial capital expense is required. Please - if you don't know, don't answer. It degrades the usefulness of the site.

- Q: is Aluminum wrotten with a 2 behnd it?

- Are you asking if it's a diatomic molecule? Because then the answer would be no. Aluminum is a metal. The only diatomic molecules are Hydrogen, Nitrogen, Oxygen, Chlorine, Flourine, Bromine and Iodine. And even those are only written when they are by themselve and not part of a chemical compound.

- Q: What are the common recycling methods for aluminum coils?

- Aluminum coils can be recycled using various methods. Mechanical recycling is a commonly employed technique. It entails shredding the coils into small pieces and then melting them to create new coils. This method is both efficient and cost-effective, as it maintains the quality of the aluminum material while allowing for its reuse. Pyrolysis is another method used for aluminum coil recycling. It involves heating the coils at high temperatures in the absence of oxygen. This process breaks down the aluminum into its constituent elements, enabling the recovery of valuable metals and other byproducts. Chemical recycling is an alternative approach for recycling aluminum coils. It involves dissolving the coils in a chemical solution to separate the aluminum from other materials. The resulting aluminum can then be utilized to manufacture new coils. Lastly, smelting is a method that can be employed for aluminum coil recycling. It revolves around melting the coils and separating impurities through electrolysis. This method facilitates the recovery of pure aluminum, which can be utilized in the production of new coils. In summary, these recycling methods play a pivotal role in reducing the environmental impact of aluminum coil production. They conserve resources, minimize waste, and promote the sustainability of the aluminum industry by encouraging the reuse of materials and decreasing the need for new aluminum production.

- Q: For an intake manifold on a car, as far as increasing the inlet air temperature which is better steel or aluminum? Assuming the cylinder heads are aluminum, and half the thickness of steel is used versus aluminum. I know that steel has a lower heat capacity than aluminum, so does this mean even in this case the steel will heat up quicker and disperse the heat into the inlet air more than aluminum? Basically which material will keep the inlet air as low as possible. I know certain plastics are better than both, but I'm just curious about these two metals. Thank you.

- Aluminum conducts heat much better than steel. That is great for keeping valves and pistons cool but it is not great for keeping heat out of the inlet air. Aluminum is much lighter than steel so it makes lighter engines.

- Q: How are aluminum coils used in the production of electronic devices?

- Aluminum coils are used in the production of electronic devices for various purposes such as providing electrical conductivity, heat dissipation, and electromagnetic shielding. These coils are typically used in components like transformers, inductors, and motors, where they help in the efficient transfer of electrical energy. Additionally, aluminum coils are often employed in cooling systems to dissipate heat generated by electronic components, ensuring their optimal performance and preventing overheating. Furthermore, aluminum coils can be utilized to create electromagnetic shields that protect sensitive electronic circuits from external electromagnetic interference, thus enhancing the overall reliability and functionality of electronic devices.

- Q: What is the balanced equation for copper (I) oxide and Aluminum?

- Copper(I) oxide is a solid and so is aluminum. Any reaction that might occur would have to be at an elevated temperature. This is a thermite reaction in which copper(I) is reduced to copper metal (molten) and aluminum is oxidized to aluminum oxide. 3Cu2O(s) + 2Al(s) -- 6Cu(s) + Al2O3(s) ========= Follow up ========== Do you mean in aqueous solution? There won't be any copper(I) chloride in aqueous solution. CuCl is very insoluble in water, but will undergo disproportionation to form Cu2+ ions and copper metal. Therefore, you would actually have a solution of copper(II) chloride. Copper(II) chloride will react with aluminum to form copper metal and aluminum ions. Ordinarily aluminum won't react with copper(II) ions. The reaction does proceed in the presence of chloride ion. This is because the chloride ion will react with the Al2O3 layer on the surface of aluminum metal to make [AlCl4]^- which exposes the aluminum metal below, and thus a reaction can occur. 3Cu2+ + 2Al(s) -- 2Al3+ + 3Cu(s)

- Q: If you were to make something from each of these.which is more expensive? aluminum or carbon fiber ?which is stronger?What would the advantages or disadvantages of each be?

- This Site Might Help You. RE: aluminum vs carbon fiber ? If you were to make something from each of these. which is more expensive? aluminum or carbon fiber ? which is stronger? What would the advantages or disadvantages of each be?

- Q: Are aluminum coils suitable for heat sinks?

- Yes, aluminum coils are suitable for heat sinks. Aluminum is a popular choice for heat sinks due to its excellent thermal conductivity and low cost. The high thermal conductivity of aluminum allows it to efficiently transfer heat away from a heat source towards the fins of the heat sink, where it can be dissipated into the surrounding environment. Additionally, aluminum is lightweight and easily formed into various shapes, making it a versatile material for heat sink applications. Overall, aluminum coils are a suitable choice for heat sinks, providing effective heat dissipation and cost-effectiveness.

- Q: How do aluminum coils compare to plastic coils in terms of durability?

- Aluminum coils generally offer superior durability compared to plastic coils. Aluminum is a highly durable material known for its strength and resistance to wear and tear. It can withstand heavy usage and is less likely to crack, break, or deform under pressure. On the other hand, plastic coils may be more prone to damage, especially when subjected to repetitive use or extreme temperatures. While plastic coils can be cost-effective and lightweight, they may not hold up as well over time. Therefore, if durability is a priority, aluminum coils are a better choice as they offer a longer lifespan and greater resistance to damage.

- Q: Can aluminum coils be used for solar panel applications?

- Yes, aluminum coils can be used for solar panel applications. They are often utilized as the base material for solar panels due to their lightweight, corrosion-resistant, and durable properties. Additionally, aluminum coils offer good thermal conductivity, enabling efficient heat dissipation in solar panels.

Send your message to us

0270a00983 Aluminum Coil - Aluminum Coated Strips for Ring-Pull 5182 H48

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords