Aluminum Channel for LED Light Strips with SGS and RoHS Certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

One of the best known properties of aluminium is that it is light, with a density one third that of steel, 2.700 kg/m3. The low density of aluminium accounts for it being lightweight but this does not affect its strength.

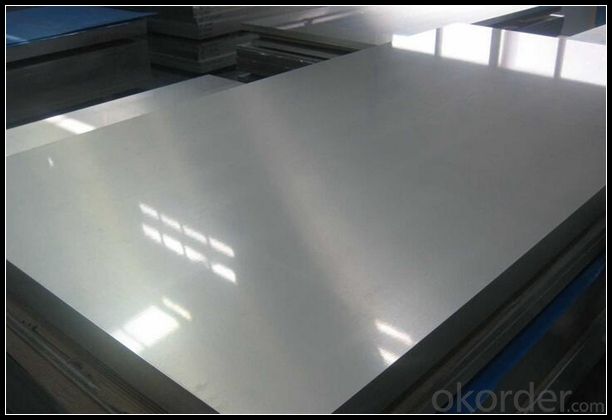

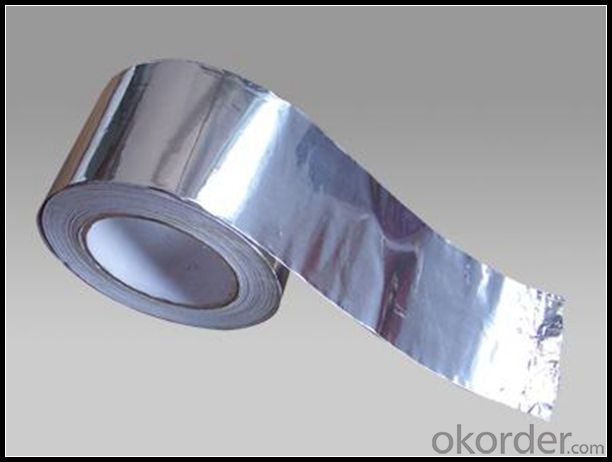

4. Image of Aluminum

5. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

6. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: This question asks for a comparison of the benefits and drawbacks associated with the use of aluminum strips.

- <p>Aluminum strips offer several advantages, including high strength-to-weight ratio, corrosion resistance, and excellent thermal conductivity. They are lightweight, which makes them ideal for applications where weight is a concern, such as in the aerospace and automotive industries. Their resistance to corrosion means they can be used in environments where other metals might rust or degrade. Additionally, their thermal conductivity makes them useful in heat exchangers and other thermal management applications. However, aluminum strips also have disadvantages. They are less rigid than some other metals, which can be a drawback in applications requiring high stiffness. They also have a lower melting point compared to metals like steel, which can limit their use in high-temperature applications. Furthermore, aluminum is a good conductor of electricity, which might be undesirable in certain electrical applications where insulation is needed.</p>

- Q: This question asks for the duration aluminum strips can last or their service life.

- <p>The lifespan of aluminum strips can vary significantly based on factors such as the environment in which they are used, the quality of the material, and the specific application. In general, if properly maintained and not exposed to harsh conditions, aluminum strips can last for several decades. For instance, in construction, aluminum strips used in framing can have a lifespan of 20 to 40 years. However, in more aggressive environments or with frequent wear and tear, this lifespan can be considerably shorter. It's important to note that aluminum is a recyclable material, and its lifespan can be extended through recycling processes.</p>

- Q: What benefits does using aluminum strips have compared to steel sheets?

- <p>Aluminum strips offer several advantages over steel sheets, including lower weight, which reduces the overall weight of products and can lead to fuel savings in transportation. They also have superior corrosion resistance, making them ideal for outdoor applications. Aluminum is easier to form and shape, which can simplify manufacturing processes. Additionally, aluminum has excellent thermal conductivity, which is beneficial in applications requiring heat dissipation. Lastly, aluminum is more environmentally friendly due to its recyclability and lower energy consumption in production.</p>

- Q: What are the characteristics of the 5052 aluminum strip?

- The 5052 main elements for magnesium alloy, with good forming performance, corrosion resistance, weldability, medium strength, used in the manufacture of aircraft fuel tank, tubing, and vehicles, sheet metal parts, ship instrument, street lamp, hardware, electrical enclosures.

- Q: Is it possible to apply paint to aluminum strips?

- <p>Yes, aluminum strips can be painted. However, proper surface preparation is crucial for good adhesion and durability of the paint. This typically involves cleaning the aluminum to remove any grease or contaminants, followed by etching or using a primer designed for aluminum to promote better paint adherence. After priming, the aluminum can be painted with a suitable paint, such as acrylic or epoxy, which are known for their compatibility with metal surfaces. It's important to follow the manufacturer's instructions for the specific paint and primer used to ensure the best results.</p>

- Q: Is there any health risk associated with the use of aluminum in food packaging?

- <p>There are some concerns about the use of aluminum in food packaging due to its potential to leach into food, especially when in contact with acidic foods. Aluminum exposure has been linked to neurological disorders, including Alzheimer's disease, although the evidence is not conclusive. The World Health Organization states that while there is no clear risk from dietary aluminum, further research is needed. It's important to note that aluminum is naturally present in many foods and drinking water, and the body can only absorb a small amount of aluminum from food packaging. Most aluminum exposure comes from natural sources, not from packaging.</p>

- Q: Is it possible to use aluminum strips for creating decorative accents or wall art?

- <p>Yes, aluminum strips can be used to create decorative accents or wall art. They are lightweight, durable, and come in various colors and finishes, making them a versatile material for crafting. You can bend, cut, and shape aluminum strips into different designs to suit your aesthetic preferences. Additionally, they are easy to install and can be used in combination with other materials to create unique and eye-catching wall art pieces.</p>

- Q: What types of aluminum alloys are known for their higher resistance to corrosion compared to other aluminum types?

- <p>Yes, certain types of aluminum alloys exhibit greater resistance to corrosion. These include 3003, 5052, and 5083 aluminum alloys, which contain magnesium and manganese, enhancing their corrosion resistance. Additionally, 6061 aluminum, which contains magnesium and silicon, is known for its good resistance to atmospheric corrosion. These alloys are often used in marine environments and other corrosive conditions due to their superior corrosion resistance.</p>

- Q: This question asks for a comparison of the pros and cons of using aluminum strips as a material for exterior cladding on buildings.

- <p>Aluminum strips for exterior cladding offer several advantages, including their lightweight nature, which reduces structural load. They are also resistant to corrosion, making them suitable for various climates and weather conditions. The ease of installation and maintenance is another benefit, as aluminum is less prone to damage and requires minimal upkeep. Additionally, aluminum strips can be easily recycled, contributing to sustainability efforts. However, there are disadvantages such as the potential for thermal expansion, which can lead to buckling or distortion over time. Aluminum may also dent or scratch more easily than some other materials, and it can conduct heat and cold, potentially leading to energy inefficiency. Lastly, while it is cost-effective in the long run, the initial installation cost can be higher compared to some traditional materials.</p>

- Q: Explain the impact of aluminum strips on indoor air quality, including any potential benefits or drawbacks.

- <p>Aluminum strips themselves do not directly affect indoor air quality. They are often used in construction and design for their strength and lightweight properties. However, if aluminum strips are improperly treated or coated with harmful chemicals, they could potentially off-gas and contribute to poor indoor air quality. Additionally, aluminum strips can sometimes be used in conjunction with air purifiers or ventilation systems, where they might help in filtering out pollutants. It's essential to ensure that any materials used in indoor spaces are safe and do not release harmful substances into the air.</p>

Send your message to us

Aluminum Channel for LED Light Strips with SGS and RoHS Certificate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords