Aluminium Grid Ceiling - Aluminum Baffle Ceiling/Color False Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

♦ Supermarkets, Shopping malls, Shops.

♦ Outdoor facilities, Gas station, Toll station.

♦ Subway Station, Railway Station, Bus station, Airport.

♦ Schools, Offices, Meeting rooms, bookstores. Stadiums.

♦ Building lobby, Corridors, Toilets.

♦ Canteens, Restaurants, Kitchen.

♦ Hotels, Hospitals, Office building, Government buildings.

♦ Museums,Tourist resort, Commercial buildings.

Product Advantages:

1.Durability:

Good materials and sophisticated fabrication technology ensure durability of ceilings throughout their lifespan;

2.Environmental:

Aluminum ceiling does not contain harmful substance to environment. The aluminum alloy is recyclable and reused;

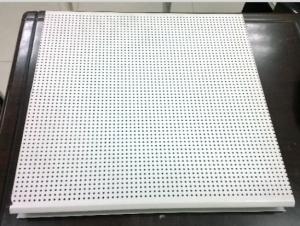

3.Sound absorbing:

Sound absorption function will be increased vastly by perforated holes and non-woven fabric, which is anti-inflammable;

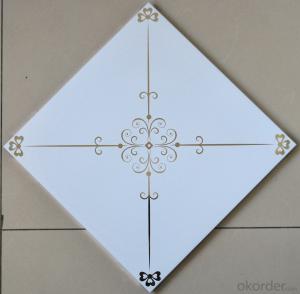

4.Beauty:

Modern style of ceiling like the u baffle ceiling and water drop screen ceiling bring a strong sense of layers. All aluminum panel ceiling can perfectly match the light system;

5.Quality control:

6 years development, we have established our quality control system to meet customer’s request, with 10-15 years quality guarantee.

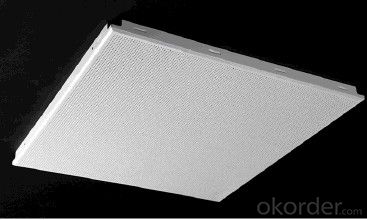

Main Product Features:

(1)Clip-in aluminum ceiling is made from high quality aluminum panels (0.6mm-1.2mm thick).

(2) International standard 1100H24, 3003H24, or 5005H24 aluminum alloy depending on requirements; galvanized iron and stainless steel are made available as well.

(3)Advantages of clip-in aluminum ceiling:

A: light weight, high strength

B: shock resistant, water proof, fire proof, anti-corrosion, anti-fouling

C: simple structure, easy installation and maintenance

D: clear edges and minimized gaps between tiles greatly improve aesthetic effects.

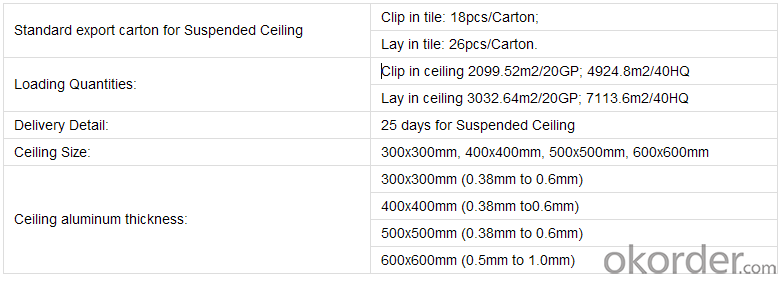

Product Specifications:

FAQ:

Q1: Is your company a manufacturer or a trading company?

A: We are a professional metal building material manufacturer with the advantage of direct and consistant quality control, more competitive pricing and smooth services. We welcome to visit our company and manufacturing site located in Shanghai, China and hope that we can foster a long-term business relationship with you.

Q2: What if I cannot find a desired model in your catalogue or online product displays?

A: With 20 years of experience in landscape projects, we are experienced and expertised to make customized products according to different designing needs. The catalogue only includes part of our standard models. Just tell us what you want to achieve or give us your drawings, and we will find a solution for you.

Q3: What is your accepted payment terms?

A: We prefer T/T,Westunion,and Paypal. We are open to the negotiation about payment terms with our clients before signing up the contract.

Images:

- Q: What is the size of the integrated ceiling plate?

- At present, the market of aluminum slab plate, including the strip of aluminum slab plate, square aluminum slab plate, metal grille, in which the most widely used strip-shaped aluminum slabs, more manufacturers, can see different specifications. Striped aluminum slabs are roughly as follows: length is generally 3 meters, 4 meters two; width of 3 cm to 30 cm between the touch a variety of specifications; plate thickness is generally between 0.4 ~ 0.9 mm. Market price of 50 to 150 yuan / square meter.

- Q: How to sub-aluminum buckle plate is good or bad?

- Look at the keel: keel is good or bad is a lot of consumers ignore the problem, the keel material is generally divided into aluminum, iron and no fingerprint steel. Aluminum keel will not rust, but because the cost is relatively high sales so very little. Iron keel is easy to rust, although the keel section hidden in the back of the ceiling generally do not see, but the rust scattered on the ceiling on the ceiling is not good, over time will affect the stability of the ceiling. No fingerprint steel keel relative to the iron keel it is not so easy to rust, is currently the most commonly used home improvement tooling sales. I sincerely hope that consumers can buy their own ideal integrated ceiling products.

- Q: The first question: what are their keel ceiling, the other used keel has no features? The second question: how are their installation methods and their keel spacing? Is there any special spacing? The third question: I hope you can provide photos of the above two questions, thank you for additional points.

- Gypsum board ceiling with light steel keel, of course, also used to make wooden keel. Light steel keel characteristics, is not easy to deformation, the top flatness is higher, fire, durable. While the keel is just the opposite. Light steel keel ceiling when the keel is connected with hanging bars, hanging tendons are fixed in the building top (bottom) surface. The distance between the keel is generally 30 cm, but there are 40 cm. Whether it is 30 cm, or 40 cm, the spacing in the normal construction conditions are fixed, may be that you say "special spacing" of the.

- Q: Are there any insulation for aluminum buckle

- Aluminum plate is a metal plate, the material is relatively thin, good thermal conductivity, difficult to heat. Only relatively thick non-metallic materials to have insulation effects, such as: polymer composite gusset plate, gypsum board and so on.

- Q: Can the ceiling of the balcony be used? My house is on the top floor, the balcony ceiling is glass. With aluminum cords hanging ceiling summer high temperature buckle plate will not deformation ah?

- Can be used is the aluminum plate will be more hot aluminum is not insulated

- Q: Kitchen and bathroom ceiling, is the aluminum plate is good? Or waterproof gypsum board is good? What are their advantages and disadvantages?

- Personally suggest that you use aluminum, you said the aluminum plate should be the integrated ceiling on the market. Advantages are easy to install and disassemble, easy to repair. Waterproof gypsum board, suitable for a larger space, foreign use more. Our kitchen or need to cook what the temperature relative to the foreign kitchen will be high, high temperature or aluminum better. If you are the pursuit of the kind of simple and stylish effect, then you can choose a little elegant aluminum, not too fancy, the effect is good.

- Q: What is an aluminum buckle? What place to use it, and gypsum board is different

- Aluminum slab plate is the ceiling material, mainly used in the top of the kitchen, there are used in the balcony or other shapes, is the metal, there is a certain water resistance, so used in the kitchen, the current majority of the aluminum plate is a square, There are stripes, patterns a lot, the color is also a lot, you can mix with the market, the integrated ceiling is the aluminum plate, as well as the specifications of the lamp or exhaust, gypsum board is the ceiling material, but it is mainly used in the guest Restaurant, modeling, you can also top shape can be facade modeling, impatience, moisture is easy to deformation

- Q: Kitchen and bathroom ceiling aluminum plate coated, oxidation and mirror what is the difference

- Kitchen and toilet ceiling of the aluminum plate is divided into many varieties and processes: coated plate is affixed to the surface of aluminum substrate film. This section of the board surface finish good color is also popular in 10 years ago, because there was no other process aluminum plate. Easy to fade is generally used only for engineering (tooling) home improvement know the owner is generally not used (of course, if it is RMB tension, then you can consider Oh). It is said that the oxidation of the oxidation plate is a good thing, the plate feel fine, aluminum anodic oxidation history of its surface produced a layer of oxide, in use it will not be in the oxidation or halogen. But the cost of high prices on your market rarely. Mirror panel is also polished mirror (in the aluminum plate directly polished out of course the price is not the end) and coated mirror (and the same film is also cheaper)

- Q: Aluminum buckle board edge of this used to do

- Is used to fix the need to cut off the buckle to make the gap between the pinch and the edge of the minimum in the fight when the glass glue more beautiful look good, no cut on the need not directly on the line

- Q: How to disassemble the ceiling

- Aluminum slabs are decorated with triangular keel card, with plastic sucker (supermarket there) can be sucked, and installed along the press on the line.

Send your message to us

Aluminium Grid Ceiling - Aluminum Baffle Ceiling/Color False Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords