Aluminum 3003 Aluminum Circle 0.05-4.0mm Thickness Circle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

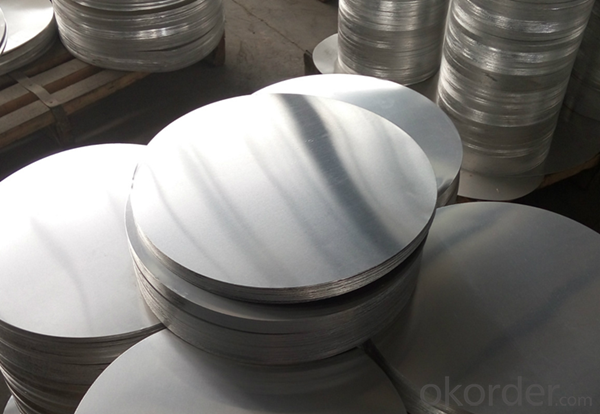

Aluminum circle & 3003aluminum circle & 0.05-4.0mm thickness circle

Packaging & Delivery

| Packaging Details: | 25kg/carton-boxes(35*32*19CM) &Fumigation wooden-pallets (110*110*15cm) 20GP can loading 22 Ton,total 21 pallets,20 CBM. |

| Delivery Detail: | within 25 days |

Specifications

1).Excellent Surface Quality for lighting reflectors.

2).Excellent deep drawing and spinning quality.

3).Anodizing Quality

Aluminium circle/Aluminium discs/disks for cooking utensils Cookware

Aluminum disc Surface Finish: Bright & smooth surface, without flow lines, slightly oiled to avoid White rusting.Smooth,Brightly ,No Zone of Fracture ,No Scratched ,No oil Sludge

We enjoy a good reputation among our customers for our aluminum circle with high quality and competitive price, win high appreciation from our clients with the excellent workman-ship and professional ability. The quality matches with ISO 9001 quality management system.

It is equipped with 5 hot tandem rolling line, 4 cold mill production lines, 4 annealing surface machines and a complete finishing equipment.

Specification:

Alloy

Temper

Specification

Thickness

Diameter

1070,1050,3003,1100

O,H12,H14,H16

0.5-5.0mm

100-1200mm

Aluminum disc chemical Properties(WT.%)

Alloy

Si

Fe

Cu

Mn

Mg

Cr

Ni

Zn

Ca

V

Ti

Other

Min.A1

1050

0.25

0.4

0.05

0.05

0.05

-

-

0.05

-

0.05

0.03

0.03

99.5

1070

0.25

0.25

0.04

0.03

0.03

-

-

0.04

-

0.05

0.03

0.03

99.7

3003

0.6

0.7

0.05-0.2

1.0-1.5

-

-

-

0.1

-

-

-

0.15

96.95-96.75

- Q: This question asks for recent applications of aluminum in the construction industry.

- <p>Aluminum has found new uses in construction due to its lightweight, durability, and sustainability. It's used in curtain walls, window frames, and doors for its strength and resistance to corrosion. Aluminum is also utilized in modular construction, where prefabricated components can be quickly assembled on-site. Its high thermal conductivity makes it suitable for energy-efficient building envelopes. Additionally, aluminum's recyclability and low environmental impact make it a popular choice for green buildings. New technologies have also enabled the use of aluminum in 3D-printed structures, offering innovative design possibilities.</p>

- Q: This question asks for typical applications of aluminum foil in everyday life.

- <p>Aluminum foil is commonly used for food storage and preservation, as it can be wrapped around food to keep it fresh. It's also widely used in cooking, particularly for baking and roasting, to prevent food from sticking to pans or to seal in moisture and flavor. Beyond culinary uses, aluminum foil is employed in arts and crafts for creating 3D structures or as a reflective surface. It's also used in insulation, as a barrier in construction, and for packing and wrapping items to protect them during shipping. Additionally, aluminum foil is utilized in various industrial processes due to its heat resistance and malleability.</p>

- Q: Can reusing old aluminum foil be utilized for cleaning tasks in kitchen or bathroom areas?

- <p>Yes, old aluminum foil can be used for cleaning purposes in a kitchen or bathroom. It's particularly effective for scrubbing pots and pans, removing burnt-on food, and cleaning glass and tiles. The shiny side of the foil can be used to remove scuff marks from floors and the dull side can be used to scrub away stubborn stains. However, it's important to avoid using foil that has been in contact with acidic or corrosive substances, as it may have become damaged or weakened, and could potentially scratch surfaces. Always test on a small, inconspicuous area first to ensure it doesn't damage the surface you're cleaning.</p>

- Q: Explain the impact of using recycled aluminum on the environment.

- <p>Using recycled aluminum significantly reduces our environmental footprint. It requires only 5% of the energy needed to produce new aluminum from raw materials, thus conserving energy. Additionally, recycling aluminum reduces greenhouse gas emissions by up to 95% compared to aluminum production from bauxite ore. This lowers air pollution and helps combat climate change. Moreover, recycling aluminum conserves natural resources and reduces the need for mining, which has its own set of environmental impacts, including habitat destruction and water pollution. Overall, recycling aluminum is a sustainable practice that benefits the environment by reducing energy consumption, emissions, and resource extraction.</p>

- Q: Is it possible to recycle aluminum and what are the benefits of doing so?

- <p>Yes, aluminum can be recycled, and it is one of the most recycled materials in the world. Recycling aluminum saves up to 95% of the energy needed to produce new aluminum from raw materials. It also reduces greenhouse gas emissions and conserves natural resources. Recycled aluminum can be used in various applications, from beverage cans to construction materials, making it an environmentally friendly and economical choice.</p>

- Q: This question asks for the amount of energy needed to produce a single aluminum ingot.

- <p>The energy required to produce an aluminum ingot varies based on production methods and efficiency. On average, it takes about 14 to 25 kWh of electricity to produce one kilogram of aluminum. This high energy consumption is due to the electrolytic process used to extract aluminum from its ore, bauxite. The Hall-H茅roult process is the dominant method, which involves passing an electric current through a bath of molten cryolite to reduce aluminum oxide to aluminum metal. Energy efficiency in aluminum production has been improving, but it remains a significant factor in the overall carbon footprint of aluminum products.</p>

- Q: What is the primary application of aluminum in various industries and everyday life?

- <p>Aluminum is most commonly used in the manufacturing of cans and packaging materials due to its lightweight, corrosion resistance, and recyclability. It is also extensively used in construction for window frames, roofing, and facades. In transportation, aluminum is a key material in the production of vehicles, particularly in the aerospace industry for aircraft and automotive industry for car bodies, due to its strength-to-weight ratio. Additionally, it is used in electrical components and electronics due to its good conductivity and malleability.</p>

- Q: What are the primary applications and benefits of aluminum in various industrial sectors?

- <p>Aluminum is extensively used in the industry due to its lightweight, high strength, and excellent corrosion resistance. It is a key material in the aerospace industry for aircraft construction to reduce weight and improve fuel efficiency. In the automotive sector, aluminum is used for engine parts and body panels to enhance fuel economy and performance. The construction industry utilizes aluminum for window frames, roofing, and structural components due to its durability and low maintenance. Aluminum is also prevalent in the packaging industry for food and beverage cans, and in electrical applications for wiring and transformers due to its high conductivity. Its recyclability makes it an environmentally friendly choice, further enhancing its industrial applications.</p>

- Q: Describe the process of manufacturing aluminum from its raw materials to the final product.

- <p>The manufacturing process of aluminum involves several key steps. Initially, bauxite ore, the primary source of aluminum, is mined. The ore is then crushed and washed to remove impurities. Next, the bauxite is processed through the Bayer process, which involves digestion in a caustic soda solution to produce a solution of sodium aluminate. This solution is then seeded with aluminum hydroxide, causing crystals to form, which are then filtered out, washed, and calcined to produce aluminum oxide, also known as alumina. Finally, in the Hall-H茅roult process, alumina is dissolved in a cryolite bath and electrolyzed to extract pure aluminum. This process involves passing an electric current through the bath, causing aluminum ions to be reduced and collected at the cathode as molten aluminum, which is then tapped off and cast into various forms for use in manufacturing.</p>

- Q: Is it possible to utilize aluminum in the construction of building materials?

- <p>Yes, aluminum can be used to make building materials. It is known for its lightweight, high strength, and resistance to corrosion, making it ideal for various construction applications. Aluminum is commonly used in window frames, roofing materials, facades, and structural components. Its durability and recyclability also contribute to its popularity in sustainable building practices.</p>

Send your message to us

Aluminum 3003 Aluminum Circle 0.05-4.0mm Thickness Circle

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords