Custom Rolled Aluminum Coil - Aluminium Prepainted Coil Serie1xxx Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

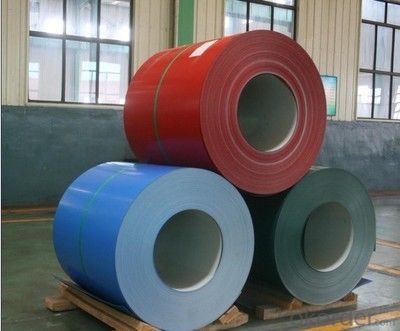

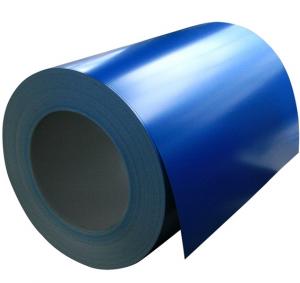

Structure of Prepainted Aluminium Coil:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Prepainted Aluminium Coil:

High intensity.

Low welding costs.

Outstanding color compatibility after anodizing

Easy to operate. All-position welding.

Excellent corrosion resistance.

Images of Prepainted Aluminium Coil:

Prepainted Aluminium Coil Specifications:

| Alloy | 1050 1060 1100 3003 3004 3005 3014 3105 3A21 5A02 5005 5052 5083 5251 6061 6063 etc |

| Temper | F O H12 H22 H14 H24 H16 H26 H18 H32 H34 H38 H111 H1112 H116 H321 T5 T6 etc |

| Thickness | 0.02mm - 1.2mm |

| Width | Standard width: 1200mm 1240mm ; Special width:1300mm 1520mm 1570mm 1595mm |

| Diameter | Standar dia: 1200mm ; Interior dia: 150mm 405mm 505mm |

| Weight | 1 T / coil -- 3 T / coil |

| Coating | PE PVDF ACRYLIC |

| Surface | Coated , Mill Finish ,Embossed |

| Color | Ral Color |

| Gloss | 10-90%(EN ISO-2813:1994) |

| Coating Thickness | PE: more than 18 micron PVDF : more than 25 micron |

Coating Hardness (pencilresistance) | More than 2 h |

| Coating Adhesion | 5J (EN ISO - 2409 : 1994 ) |

| Impact Resistance | No peeling or cracking (50kg / cm ,ASTMD - 2794 : 1993 ) |

| Flexibility(T-bend) | 2 T |

| MEK resistance | More than 100 |

| MOQ | 2 T |

| Payment Terms | TT or LC at sight |

| Applycation | Mainly in construction, decoration ,PCB materials, labels, house hold appliance ,lift, cover material ,LCD back panel, refrigeration, air conditioner ,automobile etc |

FAQ:

a: Where is your factory:

Henan Provence.

b:Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: I had a small exclusive group of friends in high school of nine people. For Christmas every year we'd have a get-together and exchange gifts. Now, I was never fond of the, He got something different! or, Why did she get a book and I got a scarf? So I would always give my friends each the same thing, but personalized for them.One year I made aluminum foil sculptures for them because I was especially poor...And they loved them! They ranged from a dragon, an elephant, a pacifier, to a tiny martini glass. I was really surprised that everyone liked them.So do you think that I could make these and sell them at craft fairs? I don't know...it's just something I've been thinking about recently and wondering if it would work.

- It would have to be something they could not make by themselves. It would have to be durable. It would also help if the sculpture is useful in some way. Hey, I am just telling you what sells, from long experience. Maybe you would like to teach a class in foil sculpture instead. Try offering a class on Craigslist and see if anyone signs up. Or you could do videos or a pamphlet and sell those on Ebay. .

- Q: Can aluminum coils be used for signage purposes?

- Signage purposes can indeed utilize aluminum coils. Aluminum, as a lightweight and versatile material, finds common use in the signage industry. It possesses exceptional resistance to corrosion, rendering it suitable for both indoor and outdoor applications. Aluminum coils are easily cut and molded into diverse shapes and sizes, enabling the creation of customized signage designs. Moreover, aluminum exhibits high durability and can endure harsh weather conditions, ensuring longevity for signage. Coils can be painted or coated with various finishes to achieve desired aesthetics, while simultaneously safeguarding against fading and scratching. Ultimately, aluminum coils remain a favored choice for signage due to their versatility, durability, and aesthetic appeal.

- Q: Aluminum coil Kaiping is out of arc plate, what's the matter?

- Aluminum coil Kaiping need to use "stretch bending straightening machine" to do leveling, before they can be leveled

- Q: What are the factors that affect the cost of aluminum coils?

- There are several factors that can affect the cost of aluminum coils. 1. Raw material costs: The cost of aluminum, which is the primary material used in manufacturing coils, can fluctuate based on global supply and demand as well as market conditions. Changes in the price of aluminum can have a direct impact on the cost of aluminum coils. 2. Manufacturing process: The production process involved in making aluminum coils can also impact their cost. Various techniques such as casting, rolling, and annealing are used, and each method has its own associated costs. The complexity and efficiency of the manufacturing process can influence the final price of the coils. 3. Size and specifications: The size, thickness, and specifications of the aluminum coils can affect their cost. Larger coils or coils with specific dimensions may require additional raw materials, processing time, or specialized equipment, which can contribute to higher costs. 4. Surface finish: The type of surface finish applied to the aluminum coils can also impact their cost. Coils with a higher-quality finish, such as brushed or coated surfaces, may be more expensive due to the additional processing and materials required. 5. Quantity and order volume: The volume of aluminum coils ordered can often impact the cost. Larger order quantities may lead to economies of scale, resulting in lower unit costs. Conversely, smaller orders or customized specifications may incur additional setup costs or higher per-unit prices. 6. Market competition: The level of competition in the aluminum coil industry can affect pricing. If there are numerous manufacturers offering similar products, prices may be more competitive as companies strive to attract customers. On the other hand, if there are limited suppliers or unique product offerings, prices may be higher due to reduced competition. 7. Transportation and logistics: The cost of transporting aluminum coils can also influence their overall price. Factors such as distance, mode of transportation, and fuel prices can impact shipping costs, which in turn can be passed on to customers. It is important to note that these factors are not exhaustive and can vary depending on the specific circumstances and market dynamics. Additionally, other external factors such as taxes, tariffs, and government regulations can also affect the cost of aluminum coils.

- Q: Can aluminum coils be used in the manufacturing of solar reflectors?

- Indeed, the utilization of aluminum coils in the fabrication of solar reflectors is plausible. The reason behind aluminum being the preferred material for solar reflectors lies in its exceptional characteristics such as high reflectivity, cost-effectiveness, and lightweight nature. Moreover, aluminum exhibits remarkable thermal conductivity and possesses resistance against corrosion, rendering it suitable for outdoor applications. The malleability of aluminum coils enables effortless shaping and formation into the desired reflector shape, thereby facilitating efficient concentration and reflection of sunlight onto solar panels or other solar energy systems. Furthermore, the sustainability of aluminum as a recyclable material amplifies its environmental advantages in the field of solar reflector production.

- Q: What is the elongation of aluminum coils?

- The elongation of aluminum coils refers to the degree to which the coils can be stretched or lengthened before they reach their breaking point. It is a measure of the material's ductility or ability to undergo plastic deformation without fracturing. Aluminum coils typically have a high elongation percentage, typically ranging from 10% to 30%, which means they can be stretched considerably before breaking. This property makes aluminum coils suitable for various applications where flexibility and resilience are required, such as in the manufacturing of electrical cables, automotive parts, and building materials.

- Q: What is the typical thermal conductivity of aluminum coils?

- Aluminum coils typically exhibit a thermal conductivity ranging from 205 to 220 W/mK. Renowned for its exceptional thermal conductivity, aluminum stands as a favored option for heat transfer purposes, notably within HVAC systems, refrigeration units, and heat exchangers. The remarkable thermal conductivity of aluminum facilitates effective dissipation and transfer of heat, thereby guaranteeing peak performance and energy efficiency in said systems.

- Q: where is aluminum found in the world or in the universe?do u think aluminum is more valuable to people than gold?why or why not?im just lazy to look up the answers and person 4 best answer 10points

- where is aluminum found in the world aluminum is in fact the third most common element in the Earth's crust, and it is the most common metallic element on Earth. In a pure form, aluminum is silvery white and extremely lightweight. aluminum is more valuable to people than gold? aluminum continues to remake the modern world. We can see it everywhere; in architecture, transportation, electrical cables, communications and consumer products. Because it’s light-weight, strong, versatile and easy to recycle, aluminum is becoming more and more valuable in our daily lives melting point and boiling point Melting Point: 933.437 K (660.323°C or 1220.581°F) Boiling Point: 2792 K (2519°C or 4566°F)

- Q: Can aluminum coils be recycled multiple times without losing their properties?

- Yes, aluminum coils can be recycled multiple times without losing their properties. Aluminum is a highly recyclable material, and the recycling process for aluminum coils involves melting the metal down to its liquid form and then reshaping it into new coils or other aluminum products. This process can be repeated over and over again without compromising the quality or properties of the aluminum. In fact, recycling aluminum requires only around 5% of the energy needed to produce new aluminum from raw materials, making it an environmentally friendly choice. Additionally, the properties of aluminum, such as its strength, durability, and resistance to corrosion, remain intact during the recycling process, ensuring that the recycled aluminum coils can be used for various applications just like the original ones. Therefore, recycling aluminum coils not only conserves valuable resources but also helps reduce waste and promote sustainability.

- Q: This question asks about the differences between 3D printed aluminum coils and traditionally manufactured aluminum coils.

- <p>Yes, there are differences between 3D printed and regular aluminum coils. 3D printed aluminum coils are manufactured using additive manufacturing, which allows for complex geometries and customization. They can be produced with less material waste and can be designed for specific applications. Traditionally manufactured aluminum coils, on the other hand, are typically made through processes like rolling, which may not offer the same level of design flexibility. 3D printed coils may have different mechanical properties due to the layer-by-layer manufacturing process, potentially resulting in varying strength and durability. Additionally, 3D printed coils might have a higher cost due to the specialized equipment and materials required for additive manufacturing.</p>

Send your message to us

Custom Rolled Aluminum Coil - Aluminium Prepainted Coil Serie1xxx Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords