Aluminium Coated Pet Film Metalizing Aluminum Mylar Mpet Film Moisture Proof Film

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated Pet film metalizing aluminum mylar mpet film Moisture proof film

Quality: 100% virgin pet

HS Code: 777309664

Processing Type: Multiple extrusion

Thinckness: 8mic-12mic

Main size: Width≤2350mm

Length 18000m/9000m/6000m

Usage: 1)PET food grade packing film2)PET printing film, pet release film

3)Metalized pet film,cpp/pet sealing film

4)Pet laminating film

Remark: All the indicators could be customized which includes the thickness, width, length, diameter.

Product Description

Aluminium coated Pet film metalizing aluminum mylar mpet film Moisture proof film

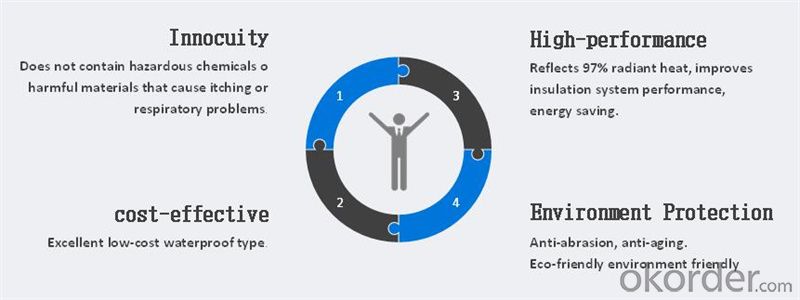

Metallized film (VMPET) is a silver color reflective film that is plated by aluminum layer on the film surface in vacuum condition which makes it high barrier resistance of oxygen and water vapor. It has glossy metallic appearance of an aluminum foil at a reduced weight and cost that can be widely used for packaging, decoration, insulation and electronics.

Our Advantage

Superiority of price: we control the whole process from raw materails purchasing to final product manufacturing.

Efficiency advantage: the fastest time of delivery is 7days.

Customization: all indicators could be customized which includes the thickness, width, length, diameter.

Device Show

- Q: What is Matt BOPP film, or matt plastic film?

- BOPP film is three layer structure, Matt film is in the outermost two layer added Matt masterbatch, the BOPP film becomes Matt effect.

- Q: Is there any toxicity in the production process of plastic blown film machine?

- Plastic blown film production process whether there is toxic or harmful gas production, mainly to see what kind of plastic. The production of polyethylene, polypropylene plastic film is not toxic, if the production of PVC plastic film, due to the heating and melting plastic parts plastic decomposition produces hydrogen chloride gas, it will cause harm to the human body.

- Q: What are the LLDPE plastic films and what are the main uses?

- The properties of the resin are generally reflected in the melt index and density. The melt index reflects the average molecular weight of the resin and is mainly controlled by the reaction temperature. The average molecular weight has nothing to do with the molecular weight distribution (MWD). The influence of catalyst selection on MWD.The density is determined by the concentration of the comonomer in the polyethylene chain. The monomer density is used to control the number of short branches (whose length depends on the type of comonomer used) to control the resin density. The higher the concentration of comonomer, the lower the resin density.Structurally, LLDPE differs from LDPE in the number and type of branched chains, while high pressure LDPE has long branched chains, while linear LDPE has only short branched chains.Structurally, LLDPE differs only from HDPE in the number of short branches. HDPE has fewer short branched chains and therefore is of higher density.The physical properties of LLDPE are controlled by its molecular weight, MWD, and density.

- Q: How many kinds of plastic film specifications are there in the greenhouse?

- In order to adapt to the various aspects of agricultural production, agricultural plastic film has a variety of different varieties and specifications. According to the use of plastic raw materials, divided into PVC plastic film and polyethylene plastic film;. According to a method of manufacturing a plastic film, divided into pressure Ting film, blown film; according to some special properties of plastic film there were no film, seedling, drop film, film, thin film, colored cover wide film, packaging film etc. according to the different width and thickness of the plastic film, there are a variety of different specifications.

- Q: Is it beneficial or harmful to wrap trees in plastic film?

- Wrapped grass first with straw or directly to the trunk wrapped with straw tied membrane, and then fixed on the trunk with fine grass. Then with the water or spray will spray wet straw, can also be careless or straw soaked and package. The plastic bag in the careless orstraw strapping on the trunk will last film. The lower part of the trunk is close to the soil ball to spread the film. After the foundation is covered with soil, it is covered with plastic film. Plastic film surrounding soil pressure, so that the use of soil temperature regulation, to ensure that the parcel trunk space is sufficient temperature and humidity, and avoid the work of adding water.

- Q: The plastic film on the TV screen doesn't need to be taken

- Protective film on the side of the TV should be torn off. The reasons are as follows.1, the protection film affixed to the edge of the TV will lead to poor cooling after the TV is started, thereby affecting the life of the components inside the tv;2, protective foil is also easy to cause the border plastic heating discoloration.

- Q: Is the foundation covered with film or damp proof powder?

- And moisture-proof powder is similar to desiccant, moisture can only be, but if the humidity is relatively large or too much water, then the performance is not as good as the film. So it is better to use film to prevent moisture on foundation, but don't damage it during construction.

- Q: How to choose PE plastic packing film

- Welding strength is also a necessary condition for plastic film bags to protect goods reliably. If the weld strength is not enough, the weld will become the fatal weakness of the plastic film bag, and the plastic bag will lose the protection to the goods because of the rupture of the weld seam.

- Q: Why are more transparent plastic films used in flower sheds instead of glass?

- Glass greenhouse installation and late maintenance is not convenient. The installation and maintenance of glass greenhouse is very inconvenient, and the economic benefits can not be effectively guaranteed.Plastic greenhouse installation is simple, demolition is also relatively simple. As the light intensity of plastic greenhouse is relatively weak, air humidity will also be improved, and its use is mostly used in seasonal cultivation facilities and fully utilized.

- Q: What solvent can be used to remove the plastic film glued to the glass?

- The range of application is suitable for diluting all kinds of nitro wood paint.Product features:1, low odor, no residue2, strong solubility, good matching3, moderate drying speed, easy construction, preferably esters, alcohols, aromatic hydrocarbons and other organic solvents, low odor, good solubility, good construction performance, applicable to dilute all kinds of nitro wood paint.

Send your message to us

Aluminium Coated Pet Film Metalizing Aluminum Mylar Mpet Film Moisture Proof Film

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords