Perforated Aluminium Ceiling - Acoustic Perforated Aluminum Ceiling Factory in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

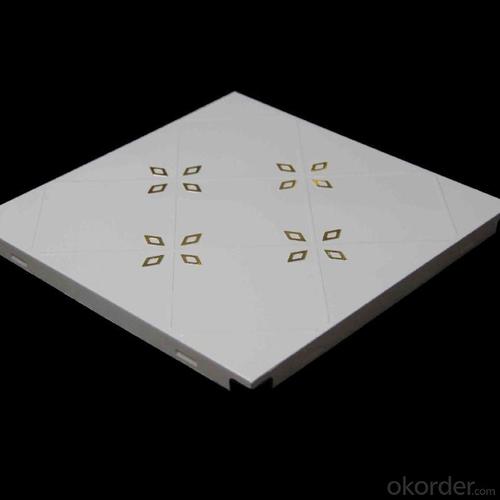

2014 New fireproof aluminum ceiling

Specification:600*600

Material: Aluminum alloy

Certification:ISO,BV, TUV

Factory price

1) Our clip in aluminum ceiling:

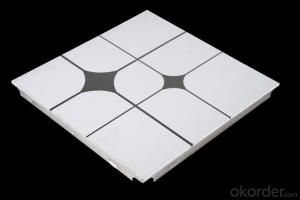

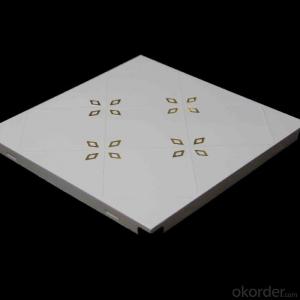

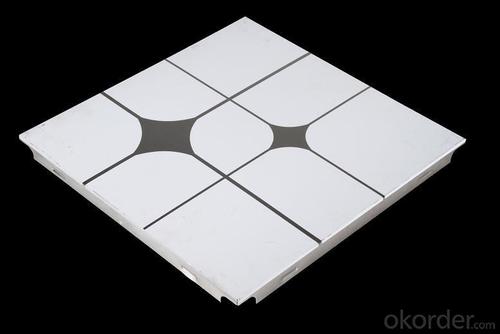

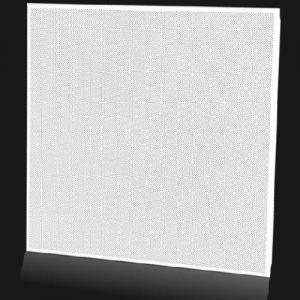

Clip in square ceiling, widest applicable among all type of ceiling with outstanding advantages. Plain or pattern can be selected according to the actual requirement. Clip in system which is concealed, steady structure, flat surface, could be both used as ceiling and wall panel.

2) Specifications:

| Ceiling Type | Size(mm) | Height(mm) | Thickness(mm) | Edge Type |

| Clip In Ceiling | 300*300 | 18/20 | 0.45~0.56 | Beveled Edge/Square Edge |

| 600*600 | 20/24/28 | 0.45~0.7 | Beveled Edge/Square Edge | |

| 800*800 | 20/24/28 | 1.0 | Beveled Edge/Square Edge | |

| 300*1200 | 20/24/28 | 0.75~0.9 | Beveled Edge/Square Edge | |

| 600*1200 | 20/24/28 | 0.75~1.1 | Beveled Edge/Square Edge | |

| Lay In Ceiling | 275*275 (295*295) | 8 | 0.60~0.70 | Square Edge |

| 575*575 (595*595) | 8/12/18 | 0.60~0.70 | Beveled Edge/Square Edge | |

| 585*585 (595*595) | 10 | 0.60~0.70 | Square Edge | |

| 585*585(605*605) | 10 | 0.60~0.70 | Square Edge | |

| 595*1195*575*1175 | 8 | 0.60~0.70 | Square Edge | |

| 603*1210*585*1195 | 8 | 0.60~0.70 | Square Edge | |

| Ceiling Type | Open size(mm) | Width & Height(mm) | Thickness(mm) | Length(mm) |

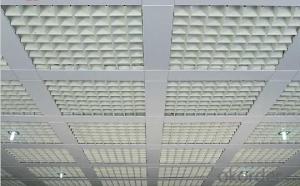

| Open Cell Ceiling | 50*50 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 |

| 75*75 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

| 100*100 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

| 125*125 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

| 150*150 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

| 200*200 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

| Ceiling Type | Width(mm) | Length(mm) | Thickness(mm) | Edge Type |

| C-strip | C100/C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

| S-strip | C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

| H-strip | C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

| G-strip | C100 | 1000~6000 | 0.45~0.85 | Square Edge |

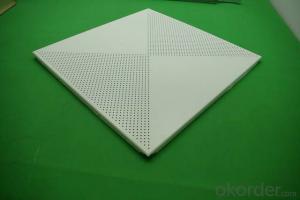

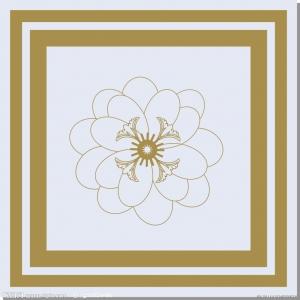

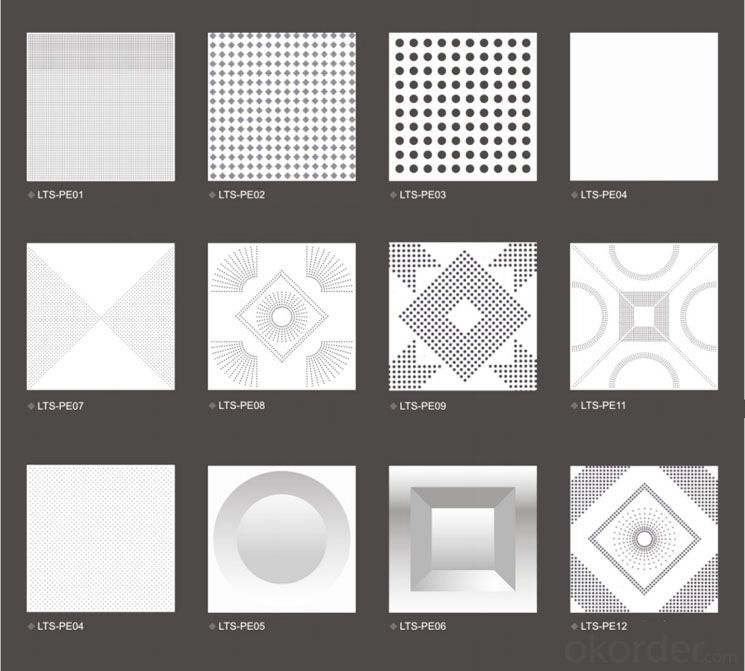

3) perforated pattern:

Perforation is a kind of processing technology for metal ceiling.Ceiling design beautiful patterns according to the arrangement of perforated holes with powerful sound absorbing and isolating effect. Rators possesses over 40 kinds of fixed perforated types, and could be customized according to client's requirements on patterns, sound absorbing to meet the actual situation.

4)Our Packing:

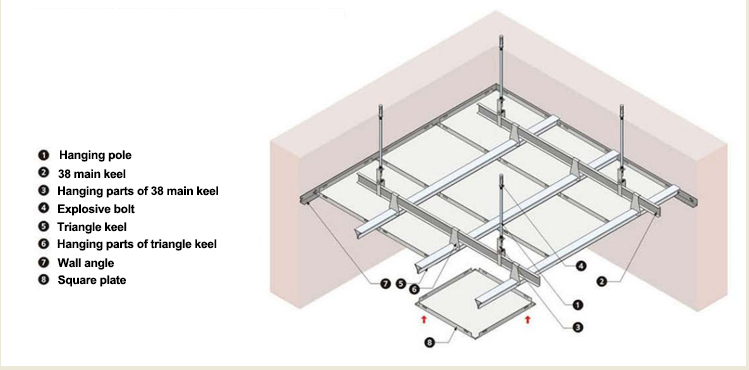

5)Installation Method:

The upper main keel and lower triangle keel are tightly connected with "cross" structure,therefore,it can assure the levelness of whole suspended system with more solid structure.

6)Sample Project:

7)Application:

mainly used in project for big area with soundproof requirements, such as hotels,stores,office building, hospitals,railway stations,metro stations and so on.

8)Certificate:

ISO9001:2008, BV,TUV, Product Quality Certificate.

9)Factory Tour:

Installaiton & Accessories.

*Clip-In Panels are constructed of recycled aluminum

*Springs and clips are constructed of high performance steel

*Clip-In Panels integrate into and conceal 15/16” face HD/ID suspension grid

*Clip-In Panels for use in interior application

*Square edge design

*Standard sizes of 24” x 24”, 24” x 48” or custom size

*Clip-In Panels available in solid or perforated designs

*Clip-in placement allows for downward accessibility without special tools

*Easily incorporates air, fire, audio and other services

*Panels contain no organic compounds that support mold or microbial growth

*Factory applied, no-VOC powder coated paints and laminated finishes

- Q: How about the quality of the ceiling

- The second generation of PVC is the first generation of the product.

- Q: Color buckle board, that is, how to install Caigang advertising Kouban it?

- Install the main keel boom: After lifting the high level of the ceiling and the keel position line, determine the height of the lower end of the boom, install the pre-machined boom, and install the boom with the 8mm diameter expansion bolt on the original top surface. Boom selection diameter of 8mm through wire, hanging bar spacing control in the 1200 mm range.

- Q: These plates are very similar in the name, but has been indispensable, I lack of knowledge Oh, what professional people to help answer! Thank you so much!

- Aluminum plate is usually used in indoor ceiling, the thickness of 0.5 to 1.0 thick, the specifications are bar and square plate and divided into film and roller, etc., aluminum veneer is usually 1.5 to 3.0 thick surface electrostatic Spray and paint, etc., can be used inside and outside the wall

- Q: Can you install a lift hanger after lifting the ceiling?

- Can, but the trouble, as long as the above reinforcement on the line, you need a long screw, through the aluminum plate fixed on the wall

- Q: Are there any insulation for aluminum buckle

- Aluminum plate is a metal plate, the material is relatively thin, good thermal conductivity, difficult to heat. Only relatively thick non-metallic materials to have insulation effects, such as: polymer composite gusset plate, gypsum board and so on.

- Q: Aluminum buckle plate and steel which is better

- Plastic plate is improved by the second generation of ceiling material PVC, also known as UPVC, steel plate is the advantage of lower prices, thermal insulation performance, rich colors, production and installation is simple. However, according to the supervision of the steel plate market supervision and inspection results show that the current market, the quality of steel products, only 40% pass rate, bending strength, coating thickness, alkali resistance and other aspects of "water" serious. And the strength of the steel plate is low, easy to twist, not environmentally friendly (UPVC can not be recycled) weather resistance is poor, the combustion will release toxic gases .. metal ceilings and aluminum plate came from behind, the current market is also divided into aluminum Several grades: the first class of aluminum-magnesium alloy, also contains part of the manganese, the material has the greatest advantage of good antioxidant capacity, and because the addition of the amount of manganese, in strength and stiffness has improved, is the best ceiling material; The The second type of aluminum-manganese alloy, the strength and stiffness of the plate is slightly better than the aluminum-magnesium alloy, but the antioxidant capacity of a slight shortage of the third type of aluminum alloy, the plate contains manganese, magnesium less, so its strength and stiffness are obvious Lower than the aluminum-magnesium alloy and aluminum-manganese alloy, the antioxidant capacity of the general .. Aluminum buckle plate is the latest in recent years, a new type of decorative materials, it has a light, water, no dust, corrosion, easy to clean, easy to install, Strong sense, soft and beautiful colors and other characteristics, is completely environmentally friendly materials, welcomed by the user. The key to choosing an aluminum plate is not the thickness

- Q: Where is the line to be done

- Clasp plate is done on the wall, can be used to expand the screw and glue the way fixed fixed edge, and then install the aluminum plate. Before installing the aluminum gusset plate, you need to install Yuba, exhaust fan (if the water heater package inside the aluminum buckle plate also need to be installed in advance). In the fixed Yuba, exhaust fans, water heaters, it is best to use expansion bolts from the top of the coagulation directly fixed, can reduce the unnecessary resonance. Kitchen first hood above the hose fixed, the lights just buy, do not need to install in advance.

- Q: Want to open a small aluminum buckle board processing plant about how much money

- Small aluminum gusset processing plant, you need to have a plant 100-300 square of the plant, part of the production workshop, part of the inventory, the other part can be used as a sample display room. The location of the traffic to facilitate the delivery of goods on it.

- Q: The original preparation of the bathroom and kitchen with aluminum plate, the decoration staff said that now with waterproof gypsum board, in the end what kind of good

- Aluminum plate for a long time or the workers will get it in the construction of the uneven, so that when the roof when the water will be dropped, the plastic plate will not be assured that the use of wood keel and on the line!

- Q: Integrated ceiling aluminum slab board know how much knowledge?

- Home decoration aluminum plate in the country according to the classification of the main types are: right angle aluminum plate and beveled aluminum plate.

Send your message to us

Perforated Aluminium Ceiling - Acoustic Perforated Aluminum Ceiling Factory in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords