High Alumina Alumina-Silicon Carbide-Carbon Refractories ASC Working Lining Bricks for Torpedo Car Iron Ladles

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alumina-Silicon Carbide-Carbon Refractories ASC Working Lining Bricks in Torpedo Car Iron Ladles

Product name, Description, Raw material, Performance & Applications

ASC refractories, short for Alumina-Silicon Carbide-Carbon (Al2O3-SiC-C) refractories, represent a cutting-edge solution for the working lining of torpedo car and iron ladles in the steel industry.

These bricks are meticulously engineered using a premium blend of raw materials, including high-grade bauxite, fused alumina, silicon carbide, graphite, antioxidants, and various additives. Expertly shaped with a phenolic resin binder, they fall under the category of non-burnt carbon composite refractory materials. The production process strictly adheres to dimensional requirements and maintains a strong commitment to high-quality standards.

Our ASC refractories are purpose-designed to excel in the demanding environments of molten metal transportation. They exhibit exceptional attributes such as thermal stability, resistance to alkalis, slag, oxidation, and erosion.

These refractories are primarily used to line hot metal pre-treatment equipment, including torpedo-type mixed iron trucks and iron ladles, during the transfer of molten metal.By choosing our ASC refractory working lining bricks, steel manufacturers can significantly enhance the efficiency and reliability of their torpedo car iron ladles and other metallurgical molten iron pre-treatment equipment.

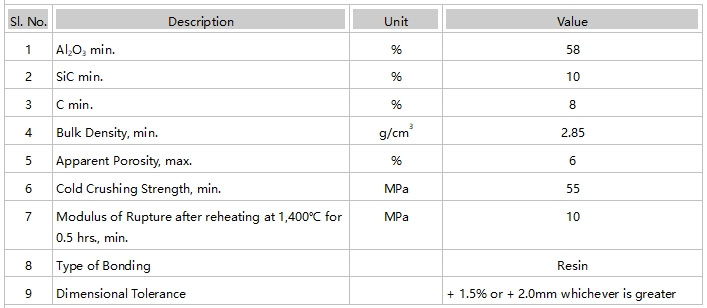

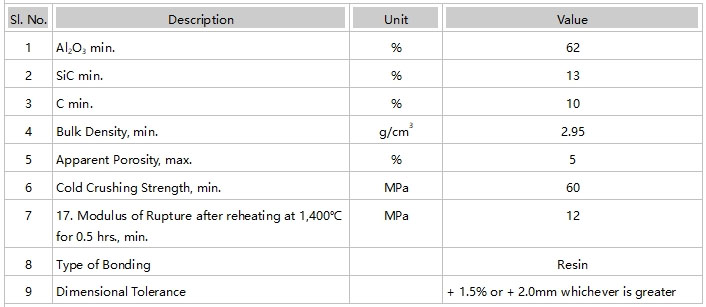

Chemistry and Physical Properties

The following tables present values for the content of Al2O3, SiC and C elements, bulk density, apparent porosity, cold crushing strength, modulus of rupture, type of bonding, and dimensional tolerance for both of the two types of ASC bricks: Standard and Three-removals.

Standard Type ASC Brick

Three-Removals Type Brick

- Three removals, referring to the removal of impurities such as phosphorus (P), sulfur (S), and silicon (Si) from the molten steel during the steel-making process. Three-Removals type bricks are specially designed to have a higher level of purity and lower impurity content than standard bricks.

Packaging

Here are some reference photos showcasing the packaging of our exporting ASC bricks. The ASC bricks are securely enclosed within robust MDF (Medium Density Fiberboard) wooden pallets or cases, with each package measuring approximately 110x100x75cm and weighing approximately 1 ton.

Contact Us

If you have specific requirements for ASC Working Lining, please inform us about the current usage of the product, existing brick types, and other information. We will adjust the content of materials based on your needs and priorities, enabling us to create a product that meets your requirements and budget. If you need us to design the brick shapes, please provide detailed torpedo tank drawings. ASC casting materials can also be produced and provided.

- Q: What are the high aluminum bricks made of?

- It's OK to use corundum bricks and alumina hollow ball bricks to build a furnace,

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- Box annealing furnace application: mainly used for quenching, normalizing, annealing and other conventional heat treatment equipment for steel parts. Features: 1, electric loading, high productivity, heat treatment is especially suitable for small and medium-sized parts, such as 30%, uniform temperature, intelligent digital display meter PID (pictured) automatic temperature control, high precision; 2, electric discharge loading convenient, as good; 3, door and seal the oven body is sealed automatically, without manual seal; 4, equipped with electric interlock protection device, and can prevent the fault accident due to the error. Bell type annealing furnace four bell type annealing furnace bell type annealing furnace is mainly used for annealing sheet metal in natural atmosphere and normalizing treatment of steel parts. 1, special steel, precision alloy large all fiber trolley type resistance furnace, strip, wire bright annealing. 2 、 annealing of special steel casting and forging. 3. Annealing of silicon steel sheet. 4, metal and non metal powder sintering pieces etc..

- Q: The cloth blowing is not uniform on the lime kiln refractory brick is damaged it

- Lining 1 yuan to prevent direct damage to the Sindh kiln high temperature flame or air, to protect the kiln carcass; 2, to prevent harmful substances (CO, SO2) erosion of the kiln body; 3, to prevent corrosion, material flow on the kiln body; 4, reduce the kiln temperature, kiln body to prevent oxidation 5, has the function of corrosion; thermal insulation; 6, to improve the coating performance.

- Q: How much is one ton / ton of high alumina refractory brick?

- The market price of about super high aluminium brick price at 3000 yuan / ton, a high aluminum brick at around 2500 yuan / ton, two high aluminum bricks at around 2100 yuan / ton three grade high alumina bricks at around 1850 yuan / ton for reference, choose to buy the area is not the same as the prices are not the same.

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Hollow brick is divided into cement hollow brick, clay hollow brick, shale hollow brick. In March 2011 Yunnan Yingjiang earthquake occurred in 5.8, the use of cement hollow brick houses collapsed and killed several people, due to safety concerns that Yunnan intends to disable the cement brick, Shandong Qingdao in the construction of real estate has also been halted the use of cement hollow brick. Professional claims in the construction industry argue that the prohibition of the use of such statements is unscientific and unprofessional. Misleading the public, it must be corrected. Hollow brick is only a kind of building material, and it is no problem to use it in scientific way. Hollow brick in use is very scientific, high quality requirements, the investigation of the foundation is suitable for the use of hollow bricks, how to design, construction, cement and other related ingredients, there are no problems. According to strict procedures, scientific use, strict implementation of relevant national standards, the use of qualified hollow bricks, there is no problem. Similarly, if the use of solid bricks does not strictly comply with the relevant standards of the state, the same will be a problem.

- Q: The difference between light high alumina brick and heavy aluminum brick

- Lightweight high alumina brick, also called high alumina insulation brick. Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. Volume density 0.4 - 1.35g/cm3. Porosity 66% - 73%, compressive strength 1 - 8MPa. Better thermal shock resistance. Usually, a high alumina clinker is added with a small amount of clay. After grinding, it is poured and shaped in the form of slurry by gas generation or foam method, and it is fired at 1300 - 1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees, I is the production of clay brick, brick my temperature at 1500-1700 degrees. Specific depends on what kiln, brick is only part of it

- Q: Use of high alumina refractory bricks?

- Because of the high Al2O3 high aluminum products, low impurity content, the formation of fusible vitreous body less so than the clay brick high load softening temperature, but because mullite crystallization has not formed the network organization, so the load softening temperature is not high silica brick.

- Q: What should be used as binder for making high alumina bricks?

- Bond for making high alumina brick: soft clay has good plasticity, so the high alumina brick is usually made of soft clay as bond. However, the free Al2O3 free SiO2 and bauxite clinker clay in under 1200 degrees occurred two times of Mullization reaction, generate large volume expansion, silicon porosity, strength reduction. Therefore, the amount of clay powder in the ingredient should be no more than 5%.

Send your message to us

High Alumina Alumina-Silicon Carbide-Carbon Refractories ASC Working Lining Bricks for Torpedo Car Iron Ladles

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords