High Alumina Brick for Torpedo Ladles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Alumina Bricks for Torpedo Ladle

Composite of High Alumina Bricks for Torpedo Ladle

High Alumina Bricks are classified according to alumina content ranging from 48% to 90%.

Main Features of High Alumina Bricks for Torpedo Ladle

Low thermal conductivity

Excellent acid and base slagging resistance

Excellent thermal shock resistance

Excellent mechanical strength

Wear and erosion resistant

Application of High Alumina Bricks for Torpedo Ladle

commonly used in blast furnace, hot blast furnace, the roof of electric furnace, teeming ladle, rotary kiln, regenerator, etc

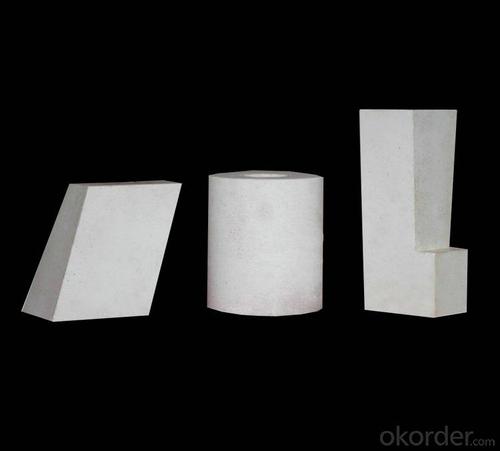

High Alumina Bricks for Torpedo Ladle Images

Specification of High Alumina Bricks for Torpedo Ladle

HIGH ALUMINA BRICK---ALP85 | |

Apparent Porosity (%) | ≤18 |

Bulk Density (g/cm3) | ≥2.85 |

Cold Crushing Strength (Mpa) | ≥80 |

Modulus Of Rupture (Mpa) | ≥20 |

Refractoriness Under Load (0.2 Mpa)(℃) | 1450 |

Permanent Linear Change (%) | 1500℃×3h -0.5 ~+0.5 |

Chemical Composition (%) |

|

Al2O3 | ≥82 |

Fe2O3 | ≤1.5 |

P2O5 | ≤3 |

FAQ of High Alumina Bricks for Torpedo Ladle

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time, we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:Is your company accept customization?

A:We have own factory and excellent technical team, and we accept OEM service.

Q6:What is the service life of your bricks?

A:The service life of different bricks is unlike. It also depends on your using condition and method.

Q7:How about your company's certification?

A:ISO9001 and Test Report, also we could apply other necessary certification.

Q8:How to solve the quality problems?

A:If the products are not confirmed to customer samples or have quality problems, our company will be responsible to make compensation for it.

Q9:What is the service life of your bricks?

A:The service life of different bricks is unlike. It also depends on your using condition and method.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- The difference between the two kinds of high alumina bricks is great. I perennial in Zhengzhou was responsible for the production and sale of colt refractories

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is one of refractory materials. The main component of this kind of refractory brick is AL2O3. High alumina brick refractory clay brick and brick than refractoriness to high. It belongs to high refractory. High alumina brick Al2O3 more, close to the neutral refractory material, can resist acid slag and alkaline slag erosion, because it contains SiO2, so the ability of alkaline slag resistance than acid resistant slag ability is weaker.According to the number of AL2O3 content is divided into, 55,65, 75,80 and so on several grades.

- Q: What is the price of the first grade high alumina brick?

- The specifications and different prices, relatively large fluctuations of the main push of the refractory Dongxin high alumina brick high alumina brick prices generally around 3000 have various levels of Dongxin refractories

- Q: What's the price of high alumina refractory bricks?

- The price of high alumina refractory bricks varies greatly according to the content of AL2O3.

- Q: The cloth blowing is not uniform on the lime kiln refractory brick is damaged it

- Lining 1 yuan to prevent direct damage to the Sindh kiln high temperature flame or air, to protect the kiln carcass; 2, to prevent harmful substances (CO, SO2) erosion of the kiln body; 3, to prevent corrosion, material flow on the kiln body; 4, reduce the kiln temperature, kiln body to prevent oxidation 5, has the function of corrosion; thermal insulation; 6, to improve the coating performance.

- Q: How to make refractory bricks and boiler wall adhesion more firm?

- If the condition, the user heat-resistant steel welding grip nails, expansion joints can not be too big.. Also to use high temperature aluminum brick, high temperature resistance, but also to extend its use cycle.

- Q: What are the specifications for bricks?

- Thecompressive node as a new type of building energy-saving wall materials, which can be used for masonry walls, but also has good thermal properties, in line with the construction of the building module, reduce the loss in the process of construction, improve work efficiency; the hole rate reached more than 35%, can reduce the weight of the wall, save the foundation engineering cost. Compared with common sintered porous brick, it has the characteristics of heat preservation, heat insulation, light weight, high strength and high construction efficiency. The product is made of shale as raw material. It is produced by high vacuum extrusion molding machine and one yard firing process

- Q: What is the apparent porosity of high alumina brick?

- Total porosity is porosity refers to the total volume of sample porosity in the percentage of total volume of samples. Apparent porosity refers to the percentage of the total volume of openings, pores, and total specimens in the sample.

- Q: How high can aluminum bricks expand at 80O degrees of heat?

- The expansion of high alumina brick is not only related to temperature, but also related to its material composition. The refractory temperature of high alumina brick is above 1770 centigrade. The temperature of 800 DEG C has little influence on the expansion of high alumina brick.

- Q: What are the categories of bricks?

- Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

Send your message to us

High Alumina Brick for Torpedo Ladles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords