Fireclay Brick with High Alumina Content Alumina for Laying Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Fire Clay Brick Features:

1. Good thermal stability, low thermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

5. Low water absorption rate, low creeping rate.

6. Natural clay products, could be shaped freely, non-radioactive and environmentally friendly.

7. Two casted method: down draft kiln and tunnel kiln. General sintering temperature: 1280-1350 degrees.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

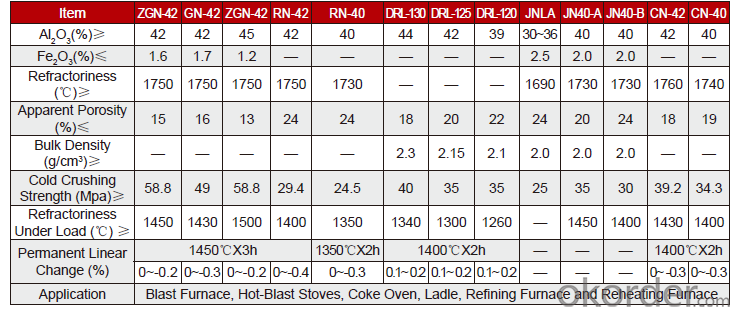

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What's the reason of cracks in refractory bricks?

- This is inorganic nonmetallic material

- Q: can the refractory sand be used to make refractory bricks?

- No...

- Q: Expansion ratio of light corundum fireproofing brick

- And then the appropriate drying, the using temperature 1500~1700 degrees of light corundum brick, the porosity is 70% to 80% Now, use foaming method to produce light corundum brick, 3g/, shaped idiosome with mould dry for 4 days in 60 degree to 70 degree oast, it will demoulding, foaming method and evaporating method produce light corundum brick, the thermal conductivity is 0. the containing of AL203 has difference, the corundum brick that use corundum hollow?sphere to produce contain the highest AL203 Finished light corundum brick don't have accurate shape and size after firing.8 1, so products need mechanical or manual cutting after the kiln, finally, firing in 1300 degree and 1550 degree, basically still meters with water forming, just add to burn: 50~60h, because its production methods and the introduction of additives are different, the total sintering time.17W/, light corundum fireproofing brick can be made into density is 0, withstand voltage strength is 4MPa, the containing of A1203 is no more than 99%.

- Q: What are the disadvantages of sintered clay bricks?

- Disadvantages: FrostPan cream also known as cream, is salting out phenomenon in the process of using brick. The excess soluble salt in the brick is affected by water absorption and dissolves when water evaporates. When the crystal is precipitated, it expands and causes the brick surface to flake. Standard: excellent products without efflorescence, first do not allow secondary efflorescence, qualified products is not allowed to have serious flooding.Lime crackingLime burst refers to brick with limestone, turn after absorbing water, because the lime burst and the expansion of the gradually maturing. This phenomenon affects the quality of bricks and reduces the strength of masonry

- Q: Can red bricks be burned in tunnel kiln which used to burn refractory brick?

- The raw material determines the production process; the output determines the kiln type; the technology determines the quality and quantity.

- Q: what kind of refractory brick is suitable for 1300 degrees converter?

- High alumina bricks of above 3 grade, containing more than 60% aluminum

- Q: What's the difference between fired clay bricks and sintered porous bricks?

- Clay, shale, coal gangue or fly ash as the main raw material, calcined by the hole rate of not less than 25%, the size of the hole is small and large number, mainly used for load-bearing parts of the brick, referred to as porous brick. At present, sintered porous bricks are divided into two types of P bricks and M bricks. As compared with ordinary clay bricks, sintered porous bricks have higher compressive strength, corrosion resistance and durability, as well as light weight and good thermal insulation performance. Sintered porous bricks can be widely used in load-bearing walls of industrial and civil buildings.

- Q: how to test the high alumina refractory brick mixed alumina?

- The first thing before producing bricks is to test whether the aluminum content reaches the standards, general testing on raw materials. Second: the shaped high aluminum brick will be tested in some professional equipment, you can know it from the professional inspection departments.

- Q: How to make refractory bricks? ? ?

- Solution of the production of refractory brick raw materials

- Q: Are clay bricks radioactive?

- Basically, any substance has radiation, because natural conditions contain a lot of radioactive particles, and even the body itself has reflective particles, such as carbon 14, but the dose is safe.

Send your message to us

Fireclay Brick with High Alumina Content Alumina for Laying Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords