Alumina Silicate Fire Brick - Wear Resistance Silica Brick & Silica Mullite Brick for Cement Kilns

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Silica Brick

CMAX silica brick is a kind of acid refractory product which is mainly made of tridymite and cristobalite, and a small amount of quartz and vitreous..

Feature of Silica Brick

Superior resistance to acids (including oxidizing)

Resistance to chlorine

Resistance to thermal shock and pressure changes

Low thermal and chemical expansion

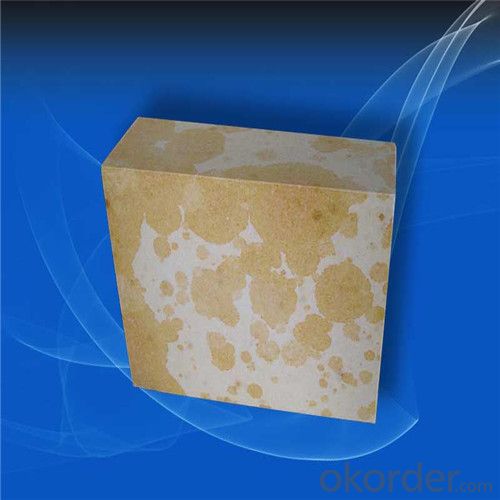

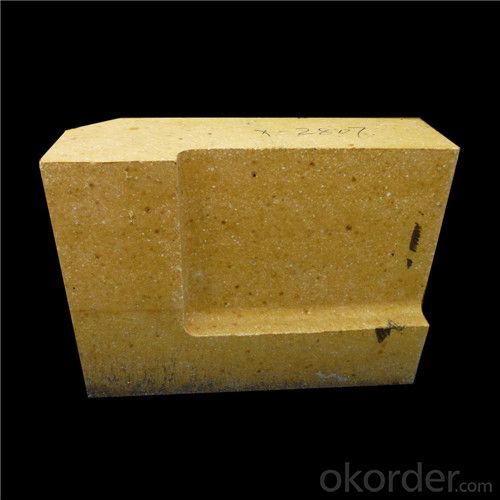

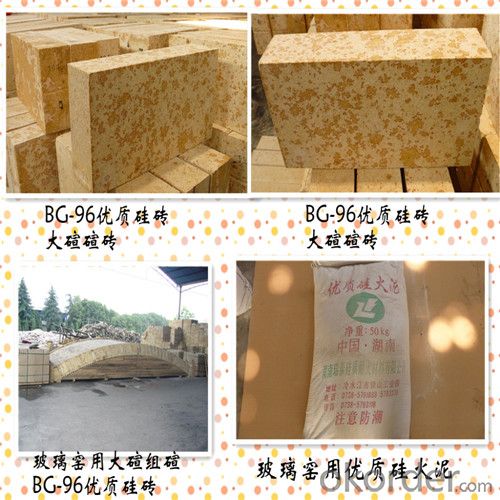

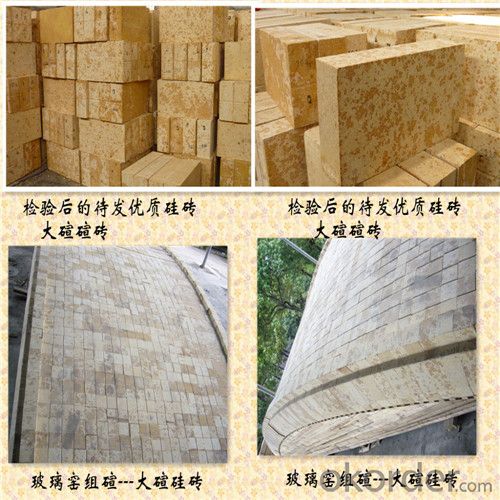

Image of Silica Brick

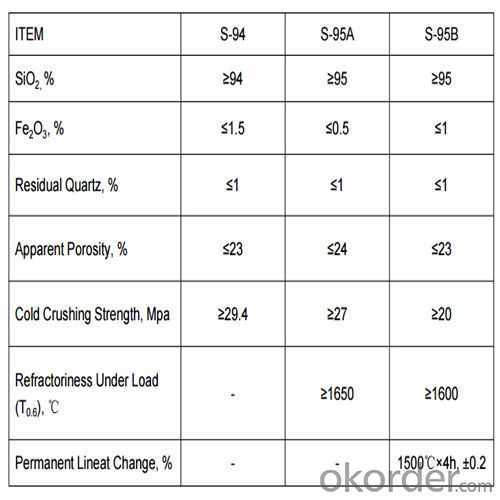

Technical Data of Silica Brick

Application of Silica Brick

Coke Oven

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

- Q: The specific content is what gb/t2608-2012 brick

- The provisions of the brick classification, technical requirements, test methods,

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The high thermal conductivity of silica brick all inherits the advantages of traditional coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity.

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick with silicon oxide content, low melt index, mainly used for glass kiln crown, parapet, wall hanging, small furnace arch superstructure and regenerator.

- Q: Which material is good for furnace refractory?

- Kiln types of refractories is very extensive, selection of refractory materials according to the type of furnace furnace temperature and use of selected refractory material, refractory material is divided into custom products of refractory bricks and unshaped refractory castable series products. According to chemistry, it is divided into acidic, neutral and alkaline materials.

- Q: What role does silica play in refractories?

- The production of clay brick refractory clay raw material is natural, its main mineral is kaolinite (formula Al2O3 - 2SiO2 - 2H2O), clay brick containing SiO2 in 45% ~ 65%, belongs to the weak acid refractory materials, have a certain ability to resist acid slag, but easy to be alkaline slag erosion.

- Q: Common bond brick?

- Manufacturing for silica brick binder hi-li sulfate pulp waste liquid and lime milk. When lime milk is used as a bond, it acts as a plasticizer. To increase the strength of lime brick in the drying process, as mineralizer in the firing, promote the transformation of quartz.

- Q: What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon, aluminum, clay and so on:

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Clay brick features good thermal shock resistance and low price, but high temperature performance is not well integrated, and the long-term use temperature is not higher than 1300 degrees. It is widely used in low temperature parts of various kilns.

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

Send your message to us

Alumina Silicate Fire Brick - Wear Resistance Silica Brick & Silica Mullite Brick for Cement Kilns

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords