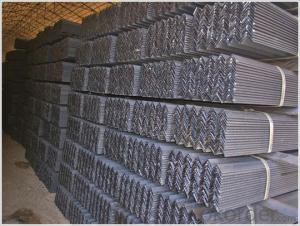

alloy hot rolled round steel bar 100*100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of American Standard Round Bar

1. Grade: ASTM A36; AISI 1006-1025

2. Sizes: Diameter: 6mm-150mm; Length: 6m, 9m, 12m or as customer’s request

3. Tolerance: Within ±5% for weight; ±2mm for diameter

4. Type: Mild steel; Low carbon steel

5. Shape: Round bar, solid bar of steel with circular section

6. Technique: Hot rolled or cold drawn

7. Mass: Mass (kg/m) = Diameter (mm) × Diameter (mm) × 0.00617

Usage and Applications of American Standard Round Bar

1. American standard is the most common form of steel as its price is relatively low while it provides material properties that are acceptable for many applications. American standard round bar is often used where large amounts of steel need to be formed, for example as structural steel.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Steel round bar is used in construction and a large number of architectural and engineering structures.

4. Some special round bar can be used for automotive engine and transmission components, bearing, rails machine tools and wire rope.

Packaging & Delivery of American Standard Round Bar

Packaging Detail: All goods are packed in bundle with steel strips and shipped by break bulk vessel or container (depend on target market and different ports)

Delivery Detail: 45 days

Trade terms: FOB, CFR, CIF

MOQ: 25 tons per specification; we can negotiate the quantity if the specification is normal or we have stock of one specification.

Weight: The price invoicing on theoretical weight basis or actual weight basis depends on customer’s request.

Shipment: The shipment of bulk break or container is depends on customer’s request and the situation of the port of destination.

Documents given: Full set of original clean on board bill of lading; Original signed commercial invoice; Original packing list; Policy of insurance; Certificate of origin and what the target market needs.

Production Flow of American Standard Round Bar

The common processes are preheated forging quenching, dual refinement solution process, cooling quenching and isothermal quenching. We use heat treatment for dual refinement solution process.

Quality Assurance of American Standard Round Bar

1. We will strictly inspect our production that we sold according to the customer’s request.

2. Quality should be in conformity with the specification of the manufacturer. Quantity and packing conditions should be in conformity with the term in the contract.

3. Should the packing found damaged, the buyer has the right to claim to the seller.

- Q: What are the advantages of using bearing steel round bars?

- Bearing steel round bars offer numerous benefits: 1. They possess remarkable strength and durability, making them ideal for applications that demand a robust and dependable material capable of withstanding heavy loads and high impact forces. 2. Their exceptional wear resistance allows them to endure constant friction and abrasion without experiencing excessive wear and tear. As a result, they are suitable for applications that involve repetitive rotational motion or sliding. 3. Bearing steel round bars are typically heat-treated to attain optimal hardness levels. This hardness enables them to maintain their shape and structural integrity even under extreme conditions like high temperatures or heavy loads. 4. These round bars exhibit excellent dimensional stability, meaning they retain their shape and size even when subjected to varying temperature and environmental conditions. This quality is essential in applications that require precise dimensions for proper functioning and performance. 5. Bearing steel round bars are often alloyed with elements like chromium and molybdenum to enhance their corrosion resistance. Consequently, they are well-suited for use in corrosive environments, such as the marine or chemical industries. 6. They are relatively easy to machine and process, allowing for efficient production and customization. This ease of shaping, cutting, and drilling makes them a cost-effective choice for various applications. In summary, bearing steel round bars offer high strength, excellent wear resistance, superior hardness, dimensional stability, corrosion resistance, and machinability. These qualities make them the preferred choice in industries such as automotive, aerospace, machinery, and construction, where reliability, durability, and performance are of utmost importance.

- Q: Are steel round bars suitable for bearing applications?

- In general, steel round bars are suitable for bearing applications. Steel possesses qualities such as strength, durability, and resistance to wear and tear, which make it an ideal material for bearing purposes. Manufacturers often utilize steel round bars in the production of bearings because they have the ability to carry heavy loads and endure rotational forces. Furthermore, steel round bars can undergo heat treatment to increase their hardness and enhance their resistance to friction and corrosion, making them even more suitable for bearing applications. Nevertheless, it is crucial to take into account the specific requirements and conditions of the bearing application to ensure that the chosen steel round bars meet the necessary standards and specifications.

- Q: How do you determine the appropriate steel grade for a specific application?

- To determine the appropriate steel grade for a specific application, it is necessary to have a comprehensive understanding of the application's requirements and the properties of different steel grades. The following steps should be considered: 1. Begin by clearly defining the specific requirements of the application, such as load-bearing capacity, corrosion resistance, temperature resistance, and durability. Take into account factors such as the environment the steel will be exposed to, the expected stress levels, and any specialized characteristics needed. 2. Research the various steel grades available in the market once the application requirements are understood. Identify steel grades known for possessing the desired properties required for the specific application. Consult industry standards, expert opinions, and available resources to gain insights into different steel grades and their performance in similar applications. 3. Analyze the physical, mechanical, and chemical properties of the steel grades under consideration. Evaluate key properties such as strength, ductility, toughness, hardness, corrosion resistance, weldability, and formability. Compare these properties with the application requirements to determine which steel grades align best with the specific needs. 4. Evaluate the cost and availability of the steel grades that meet the application requirements. Take into account factors such as the initial cost, maintenance costs, and availability of the steel grade in the required form and quantity. This step ensures that the chosen steel grade is not only suitable but also feasible from an economic perspective. 5. Seek advice from experts, such as metallurgists or engineers, to gain valuable insights into selecting the appropriate steel grade. Their expertise and experience can help weigh the pros and cons of different steel grades, identify potential challenges, and suggest alternatives or modifications if necessary. 6. If feasible, conduct testing or trials using samples of the selected steel grade to assess its performance under real-world conditions. This step can help validate the suitability of the chosen steel grade and identify any unforeseen issues or areas for improvement. By carefully considering the application requirements, researching steel grades, evaluating material properties, considering cost and availability, seeking expert advice, and conducting testing and trials, one can effectively determine the appropriate steel grade for a specific application.

- Q: What are the different surface treatments for steel round bars?

- There are several different surface treatments available for steel round bars, including galvanizing, chrome plating, powder coating, and nitriding. These treatments are applied to enhance the corrosion resistance, durability, and appearance of the steel bars.

- Q: Do you need paint for roof lightning proof steel bars?

- The roof lightning protection round steel is the use of metal electrical conductivity and the principle of point discharge, the accumulation of the earth's electricity more rapidly spread to the air, play a role in lightning.

- Q: Can steel round bars be used for making electrical system components?

- Yes, steel round bars can be used for making electrical system components. Steel is a versatile material that has many applications in various industries, including electrical engineering. While other materials like copper are commonly used for electrical components due to their high electrical conductivity, steel can still be utilized for certain parts of an electrical system. Steel round bars can be used to manufacture structural components, supports, enclosures, or mounting brackets for electrical devices. Additionally, steel's durability, strength, and resistance to corrosion make it a suitable choice for electrical system components that require robust construction or protection from environmental factors. However, it is important to note that steel is not a good conductor of electricity compared to materials like copper or aluminum, so it may not be suitable for components that require high electrical conductivity.

- Q: What are the different types of steel round bar sizes?

- There are various sizes available for steel round bars, each serving different purposes and applications. The most common steel round bar sizes range from 1/8 inch to 24 inches in diameter. These sizes are typically measured in inches, with each increment representing a larger diameter. For smaller projects or more intricate designs, steel round bars in sizes ranging from 1/8 inch to 1 inch are often used. These smaller sizes are commonly found in jewelry making, crafting, and smaller construction projects. For larger-scale applications such as structural support, manufacturing, or industrial projects, steel round bars with sizes ranging from 1 inch to 24 inches are utilized. These larger sizes provide enhanced strength and durability, making them suitable for heavy-duty use. It's important to note that steel round bars can also be found in metric sizes, which are measured in millimeters. Metric sizes are commonly used in regions that follow the metric system, such as many countries in Europe and Asia. The selection of the appropriate steel round bar size depends on the specific requirements of the project, including load-bearing capacity, structural integrity, and overall design. It's recommended to consult with an engineer or industry professional to determine the best size for your specific application.

- Q: How do you determine the strength and hardness of a steel round bar?

- To assess the strength and hardness of a steel round bar, a variety of tests and techniques can be utilized. The tensile strength test is a frequently employed method. During this test, an increasing load is applied to a sample of the steel round bar until it reaches its breaking point. The maximum load it can endure before breaking is recorded, providing an indication of the bar's strength. Another essential measure of steel round bar quality is hardness testing. The Rockwell hardness test is commonly used, involving the pressing of a diamond or tungsten carbide ball into the bar's surface with a specific load. The depth of the resulting indentation is measured, and the hardness value is determined according to a standardized scale. Additionally, the Brinell hardness test can be employed, which entails pressing a hardened steel ball into the round bar's surface with a specific load. The diameter of the resulting indentation is measured, allowing for the calculation of hardness based on the applied load and indentation size. Furthermore, non-destructive techniques such as ultrasonic testing and magnetic particle inspection can offer insight into the steel round bar's internal structure, defects, and cracks, indirectly indicating its strength and hardness. It is crucial to acknowledge that various factors, including steel composition, heat treatment, and manufacturing processes, can influence the strength and hardness of a round bar. Therefore, consulting relevant standards and specifications that define the expected properties for the specific type of steel round bar being tested is advisable.

- Q: What is the difference between carbon steel and stainless steel round bars?

- The composition and properties of carbon steel and stainless steel round bars differ significantly. Carbon steel round bars are composed primarily of iron and carbon, with trace amounts of other elements. They are renowned for their strength and durability, making them ideal for use in industries like construction and automotive. In terms of affordability, carbon steel round bars are generally more cost-effective than stainless steel round bars. In contrast, stainless steel round bars are a type of steel alloy that contains a minimum of 10.5% chromium. This addition of chromium gives stainless steel its distinct properties, including resistance to corrosion. As a result, stainless steel round bars are highly resistant to rust and staining, making them suitable for use in environments exposed to moisture and chemicals. Industries such as food processing, medical equipment, and marine applications commonly utilize stainless steel round bars. The chromium content in stainless steel round bars generally leads to higher prices compared to carbon steel round bars. However, the added cost is justified by the superior corrosion resistance and aesthetic appeal of stainless steel. Furthermore, stainless steel offers a range of grades and finishes, allowing for customization based on specific requirements. In conclusion, the primary distinction between carbon steel and stainless steel round bars lies in their composition and properties. Carbon steel is known for its strength and affordability, while stainless steel provides corrosion resistance and various customization options. The choice between the two depends on the specific application and the desired properties required for the project.

- Q: Can steel round bars be used for making valves or fittings?

- Yes, steel round bars can be used for making valves or fittings. Steel is a common material choice for valves and fittings due to its strength, durability, and resistance to corrosion. Steel round bars can be machined or forged into the desired shape for valves or fittings, ensuring that they meet the necessary specifications and requirements. Additionally, steel round bars can be heat-treated to enhance their mechanical properties and make them suitable for high-pressure or high-temperature applications. Overall, steel round bars are a versatile and reliable material option for manufacturing valves or fittings.

Send your message to us

alloy hot rolled round steel bar 100*100

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords