AISI304 201 316 321 430 stainless steel coil JIS EN DIN GB ASTM standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

AISI304 201 316 321 430 stainless steel coil JIS EN DIN GB ASTM standard

Product Description

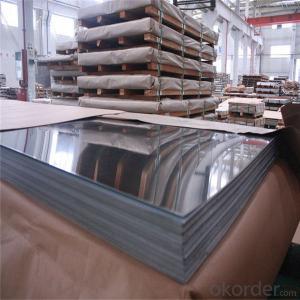

Description of stainless steel coil

Product name | AISI304 201 316 321 430 stainless steel coil JIS EN DIN GB ASTM standard |

Specification | Thickness: Cold rolled: 0.03-3mm, Hot Rolled: 3-120mm Width: 100-2000mm Length: 1000-6000mm or coil Customized sizes are accepted |

Standard | ASME, ASTM, EN, BS, GB, DIN, JIS, etc |

Finish | NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish and so on |

Material | 201, 202, 304, 304L, 310S, 316, 316L, 309s, 321, 410, 420, 430, 441, 904L |

Brand Name | TISCO, Bao Steel, LISCO, JISCO, ZPSS, KRUPP |

Place of Origin | Shanxi of China (Mainland) |

Technical treatment | Cold Rolled, Hot Rolled |

Port of Loading | Tianjin, Shanghai, Ningbo, Guangzhou |

Terms of Delivery | FOB, CFR, CIF, CNF, EX-WORK |

Terms of Payment | L/C, T/T (30% deposit) |

Packing | Standard export sea-worthy packing |

Delivery time | Within 7-15 days after receive 30% deposit or as your requirement |

Stock | Ready in stocks |

What is stainless steel used for?

Stainless steels of various kinds are used in thousands of applications. The following gives

a flavour of the full range:

Domestic – cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

Architectural/Civil Engineering –cladding, handrails, door and window fittings, street furniture, structural sections, reinforcement bar,

lighting columns, lintels, masonry supports

Transport – exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles

Chemical/Pharmaceutical – pressure vessels, process piping.

Oil and Gas – platform accommodation, cable trays, subsea pipelines.

Medical – Surgical instruments, surgical implants, MRI scanners.

Food and Drink – Catering equipment, brewing, distilling, food processing.

Water – Water and sewage treatment, water tubing, hot water tanks.

General – springs, fasteners (bolts, nuts and washers), wire.

Our Services

Stocks of stainless steel coil

| Stock Sizes | 0.3mmx1000mm / 1220mm / 1250mm 0.5mmx1000mm / 1220mm / 1250mm 0.8mmx1000mm / 1220mm / 1250mm 1.0mmx1000mm / 1220mm / 1250mm 1.2 mmx1000mm / 1220mm / 1250mm 1.5 mmx1000mm / 1220mm / 1250mm 2.0 mmx1000mm / 1220mm / 1250mm 2.5 mmx1000mm / 1220mm / 1250mm 3.0 mmx1000mm / 1220mm / 1250mm / 1500mm 4.0 mmx1000mm / 1220mm / 1250mm / 1500mm 5.0 mmx1000mm / 1220mm / 1250mm / 1500mm 6.0 mmx1000mm / 1220mm / 1250mm / 1500mm

|

Factory fecilities of stainless steel coil

Our company processing center is located in Tianjin.We have Nova cutting machine,

laser cutting machine,shearing machine,slitting machine,mirror polishing machine,

plate polishing machine,grinding machine,water jet cutting machine,red flower

machine,plasma cutting machine,large CNC milling machines,boring machines,

and many other processing equipment,we could provide a wide range of

personalized services according to customer needs.

Packaging & Shipping

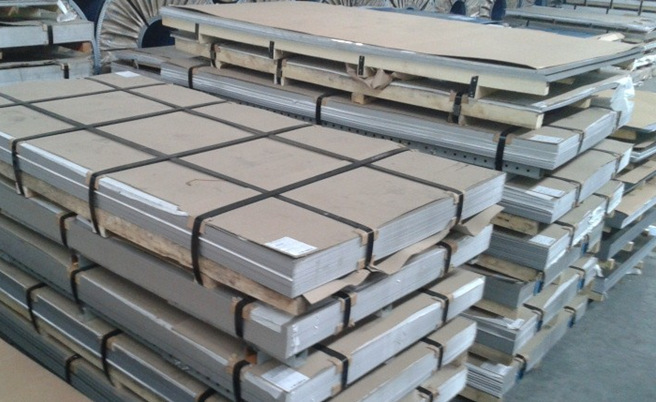

5.Packaging--stainless steel coils

- Q: Are stainless steel strips resistant to chloride stress corrosion cracking?

- Generally, stainless steel strips exhibit resistance to chloride stress corrosion cracking. The corrosion resistance properties of stainless steel are widely recognized, encompassing resistance to chloride stress corrosion cracking. This is attributed to the abundance of chromium in stainless steel, which generates a protective oxide layer on the material's surface, prohibiting the infiltration of chloride ions and subsequent corrosion. Nevertheless, it is vital to acknowledge that the resistance to chloride stress corrosion cracking may fluctuate depending on the specific stainless steel type and grade, as well as the environmental conditions in which the material is exposed. Thus, it is always advisable to refer to the manufacturer's specifications and guidelines to ensure the appropriate stainless steel grade is chosen for the intended application.

- Q: What is the thermal conductivity of stainless steel strips?

- The thermal conductivity of stainless steel strips can vary depending on the specific alloy and grade used. On average, stainless steel has a thermal conductivity ranging from 14 to 19 watts per meter-Kelvin (W/m-K). However, it is important to note that the thermal conductivity can be influenced by factors such as temperature, composition, and the presence of other elements in the alloy. Therefore, it is recommended to consult the manufacturer or specific technical data sheets for accurate and precise thermal conductivity values for a particular stainless steel strip.

- Q: How do stainless steel strips resist embrittlement?

- Stainless steel strips resist embrittlement due to their unique composition, which includes a high percentage of chromium. Chromium forms a protective oxide layer on the surface of the steel, preventing corrosive elements from penetrating and causing embrittlement. Additionally, the presence of other alloying elements like nickel and molybdenum further enhances the resistance to embrittlement by improving the steel's ability to withstand high temperatures and corrosive environments.

- Q: Can stainless steel strips be used in pharmaceutical packaging?

- Yes, stainless steel strips can be used in pharmaceutical packaging. Stainless steel is often used in the pharmaceutical industry due to its corrosion resistance, durability, and ease of cleaning. It is commonly used for manufacturing vials, syringes, and other packaging materials to ensure the safety and integrity of pharmaceutical products.

- Q: What are the advantages of using precision rolled 111 stainless steel strips?

- Precision rolled 111 stainless steel strips offer several advantages. Firstly, their precise dimensions ensure uniformity and accuracy in various applications, resulting in improved product quality and performance. Secondly, the superior surface finish of these strips enhances their corrosion resistance, making them highly durable and long-lasting. Additionally, precision rolling eliminates the need for further processing, saving time and reducing costs. Lastly, their excellent mechanical properties, including high strength and toughness, make them suitable for demanding environments and applications.

- Q: Can stainless steel strips be used in nuclear power plants?

- Stainless steel strips are indeed applicable for utilization in nuclear power plants. Due to its exceptional resistance against corrosion, high strength, and heat resistance properties, stainless steel is widely employed in the construction of nuclear power plants. It finds application in numerous areas such as the manufacturing of reactor vessels, steam generators, piping systems, and various other components. The choice of stainless steel in these settings is due to its ability to endure the severe conditions and elevated temperatures associated with nuclear power generation. Furthermore, stainless steel exhibits a high level of resistance to radiation damage, which makes it an ideal material for use in nuclear power plants.

- Q: Can stainless steel strips be plated or coated with other metals?

- Yes, stainless steel strips can be plated or coated with other metals through various processes such as electroplating or physical vapor deposition (PVD). This allows for enhancing the appearance, improving corrosion resistance, or adding specific properties to the stainless steel strips.

- Q: Can stainless steel strips be used in the pulp and paper industry?

- Yes, stainless steel strips can be used in the pulp and paper industry. Stainless steel is a versatile and corrosion-resistant material that is highly suitable for various industrial applications, including the pulp and paper industry. Stainless steel strips can be utilized in the production of various components and equipment used in pulp and paper manufacturing processes. They can be used for fabricating screens, filtration systems, rotary vacuum filters, and other equipment that require high strength and resistance to corrosive substances such as chemicals, acids, and moisture. The excellent corrosion resistance properties of stainless steel make it an ideal choice for the pulp and paper industry, where the presence of harsh chemicals and high humidity can cause rapid deterioration of equipment made from other materials. By using stainless steel strips, manufacturers can ensure longer equipment lifespan, reduced maintenance costs, and improved production efficiency. Furthermore, stainless steel is known for its hygienic properties, making it suitable for applications in the production of food-grade paper products. It is also easy to clean and maintain, which is crucial in industries where cleanliness and hygiene are paramount. In summary, stainless steel strips can indeed be used in the pulp and paper industry due to their corrosion resistance, strength, and hygienic properties. Their use can enhance the performance, durability, and efficiency of equipment, contributing to a more sustainable and productive manufacturing process.

- Q: Are stainless steel strips suitable for roofing applications?

- Indeed, roofing applications can benefit from the suitability of stainless steel strips. The exceptional resistance of stainless steel to corrosion renders it an outstanding selection for roofing materials, particularly in regions that endure severe weather conditions or heightened pollution levels. The durability, longevity, and minimal maintenance requirements of stainless steel strips make them a cost-effective alternative in the long term. Moreover, due to its high strength-to-weight ratio, stainless steel can bear substantial loads without compromising the structural integrity of the roof. Additionally, stainless steel strips are impervious to fire and possess the ability to reflect sunlight effectively, thus reducing heat absorption and subsequent energy expenses. In conclusion, stainless steel strips represent a dependable and pragmatic choice for roofing applications.

- Q: Are stainless steel strips resistant to chemicals?

- Stainless steel strips are generally resistant to chemicals. They possess a notable resistance against corrosion due to the presence of chromium in the alloy. The chromium creates a protective layer on the steel's surface, thereby rendering it resistant to oxidation and staining. Additionally, this protective layer prevents the steel from reacting with chemicals and corrosive substances, making stainless steel strips highly resistant to chemical damage. However, it is important to acknowledge that the level of resistance can vary depending on the specific grade of stainless steel and the nature of the chemical it encounters. In certain instances, particular chemicals or concentrations may still lead to corrosion or damage the stainless steel. Thus, it is always advisable to consult the manufacturer or a corrosion specialist to ensure the appropriate grade of stainless steel is selected for specific chemical environments.

Send your message to us

AISI304 201 316 321 430 stainless steel coil JIS EN DIN GB ASTM standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords