Hot Rolled Alloy Structural Steel Round Bar SCM440

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Alloy Structural Steel Round Bar SCM440

Technical Paramenters

| Standard | Grade | C | Cr | Mo | Si | Mn | P | S | Ni | Cu |

| GB | 42CrMo | 0.38-0.45 | 0.90-1.20 | 0.15-0.25 | 0.17-0.37 | 0.50-0.80 | 0.035 | 0.035 | 0.3 | 0.3 |

| JIS | SCM440 | 0.38-0.43 | 0.90-1.20 | 0.15-0.30 | 0.15-0.35 | 0.60-0.90 | 0.03 | 0.03 | 0.25 | 0.3 |

| ASTM | 4140 | 0.38-0.43 | 0.80-1.10 | 0.15-0.25 | 0.15-0.35 | 0.75-1.00 | 0.035 | 0.04 | — | — |

| ENISO | 42CrMo4 | 0.38-0.45 | 0.90-1.20 | 0.15-0.30 | ≤0.40 | 0.60-0.90 | 0.035 | 0.035 | — | |

| Grade | aisi4140 astm4140 sae4140 42CrMo,1.7225,scm440,42CrMo4 |

| Processing | EAF+LF+VD |

| Commodity | steel round bar/round steel bar/round bar steel |

| Technique | hot rolled |

| Diameter | 10-310mm |

| Length | canbe required to 3-12m |

| Sizes tolerance | length: +/-100mm,straightless:3mm/m |

| Application | 1) General service industries (petroleum, food, chemical, paper, fertilizer, Fabric, aviation and nuclear) 2) Fluid, gas and oil transport 3) Pressure and heat transmission 4) Construction and ornament 5) Boiler heat exchangers |

| Advantages of this material | 1) High fatigue strength and impact resistance after tempering 2) Good low-temperature impact toughness 3) No obvious temper brittleness |

| Quality Condition | 1): Straightness: 3mm/m (max) 2): Corner Radius: 3(max) 3): The ends will be end cut or gas cut 4): No cracks on the surface |

| Packing | 1): Paint oil on the surface to protect steel bars from rusting. 2): Bundle packing by Iron Strips. 3): Bundle weight is from 2mt to 3 mt. 4): Two or three tags will be attached on each bundle. |

| MOQ | 5 tons for each sizes |

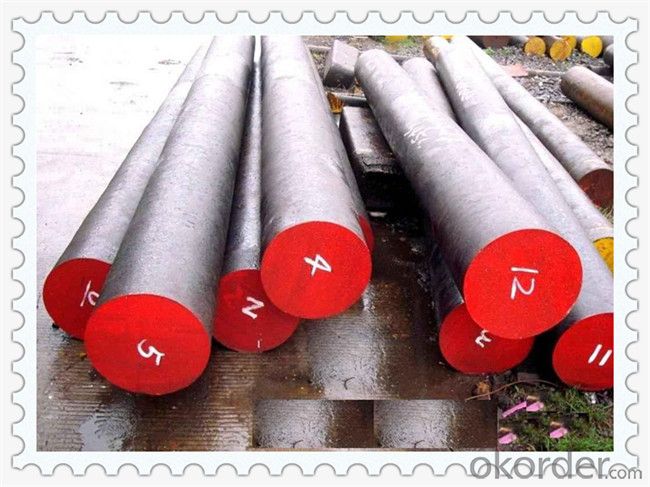

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What is the Young's modulus of a steel round bar?

- The Young's modulus of a steel round bar is a measure of its stiffness or elasticity. It is a material property that determines how much a material deforms under a given load and is defined as the ratio of stress to strain. For steel, the Young's modulus typically ranges from 190 to 210 gigapascals (GPa). This means that for every unit of stress applied to the steel round bar, the strain experienced by the bar is approximately 190 to 210 times greater. The actual Young's modulus of a specific steel round bar may vary depending on various factors such as the specific grade of steel, its composition, and any heat treatment it has undergone. Therefore, it is important to consult the relevant material specifications or conduct specific testing to determine the exact Young's modulus for a particular steel round bar.

- Q: Can steel round bars be machined?

- Steel round bars have the capability to undergo machining. Machining is a procedure that entails eliminating material from a workpiece in order to achieve the desired form, size, or texture. Steel round bars are frequently machined for the purpose of creating various components, including shafts, bolts, and fasteners. Turning, milling, drilling, and grinding are some of the machining processes that can be employed to shape and cut the steel round bars. However, the machinability of steel can differ depending on factors such as the steel's composition, hardness, cutting tools, and machining parameters. It is crucial to employ appropriate machining techniques and tools in order to ensure accurate and efficient outcomes when machining steel round bars.

- Q: What are the differences between the products made of wrought round steel and hot rolled round steel and tested by mechanical testing after heat treatment?

- The longitudinal and transverse properties of the free forging or hammer forgings are relatively small, the banded structure is not obvious, and the plastic inclusions are less deformedIt is not suitable to use rolled material for the workpiece with higher requirement of transverse or tangential performanceSampling position should be the same, usually in accordance with standards or technical requirements, such as vertical performance of a three pull, take at 2/3R

- Q: What are the advantages of using shock-resistant steel round bars?

- Using shock-resistant steel round bars in various applications has numerous benefits. Firstly, these round bars are specifically designed to withstand high impact and shock loads, making them perfect for industries like construction, automotive, and manufacturing. Their shock resistance ensures that they remain intact and maintain structural integrity, even in extreme conditions. Furthermore, shock-resistant steel round bars offer enhanced durability. They are made from high-quality steel alloys engineered to provide superior strength and resistance to wear and tear. This makes them highly resistant to bending, cracking, and fracture, resulting in a longer lifespan compared to regular steel round bars. Moreover, these round bars improve safety in applications where there is a risk of impact or sudden loads. By using them, the likelihood of structural failure or catastrophic accidents is significantly reduced, ensuring a higher level of security for workers and the overall operation. Additionally, shock-resistant steel round bars are known for their excellent machinability and weldability. This means they can be easily shaped, cut, and welded to meet specific requirements, allowing for versatility in design and manufacturing processes. This ease of manipulation makes them a preferred choice for projects requiring customization. Furthermore, shock-resistant steel round bars offer cost-effective solutions. Their high durability and resistance to wear mean they require less frequent replacements, resulting in reduced maintenance and replacement costs. Additionally, their ability to withstand shock loads reduces the need for additional reinforcement or support structures, further decreasing overall project expenses. In conclusion, the advantages of using shock-resistant steel round bars include high impact resistance, enhanced durability, improved safety, excellent machinability, and cost-effectiveness. These properties make them a reliable and efficient choice for a wide range of applications, ensuring long-lasting and reliable performance.

- Q: What are the different types of steel round bar surface finishes used in the marine industry?

- In the marine industry, there are several different types of steel round bar surface finishes that are commonly used. These finishes serve various purposes and have specific characteristics that make them suitable for specific applications. Here are some of the most common types of steel round bar surface finishes used in the marine industry: 1. Polished Finish: A polished finish is achieved by grinding the surface of the steel round bar to a smooth and reflective surface. This finish is commonly used in applications where aesthetics are important, as it provides a visually appealing and shiny appearance. Polished finishes are often used for decorative purposes on boat fittings, handrails, and other exposed areas. 2. Mill Finish: Mill finish refers to the surface condition of steel round bars as they come from the mill without any additional treatment. This finish is characterized by a rough and dull appearance, as it is not meant to be visually appealing. Mill finishes are typically used when a smooth or polished surface is not necessary, such as in structural applications or where the material will be painted or coated. 3. Shot Blasted Finish: Shot blasting is a surface treatment process that involves propelling small steel shots at high velocity onto the surface of the round bar. This process removes any surface impurities, scales, or rust, resulting in a clean and slightly textured finish. Shot blasted finishes are commonly used in marine applications where improved adhesion of coatings or paint is required, as the textured surface provides a better bonding surface. 4. Hot Rolled Finish: Hot rolled finish is achieved by subjecting the steel round bar to high temperatures during the manufacturing process, followed by rapid cooling. This process results in a scaly surface with a rough texture. Hot rolled finishes are suitable for marine applications where corrosion resistance is not a primary concern and where the material will be further processed or coated. 5. Galvanized Finish: Galvanizing is a process of applying a protective zinc coating to the surface of the steel round bar. This finish provides excellent corrosion resistance, making it ideal for marine applications where the material will be exposed to saltwater or harsh environmental conditions. Galvanized finishes are commonly used for boat trailers, marine hardware, and other components that require enhanced protection against corrosion. These are just a few of the different types of steel round bar surface finishes used in the marine industry. Each finish has its own unique properties and advantages, allowing for a wide range of applications in the maritime sector. The choice of finish depends on factors such as aesthetics, corrosion resistance, coating compatibility, and the specific requirements of the marine application.

- Q: Can steel round bars be used in the textile industry?

- No, steel round bars are not typically used in the textile industry. Textile manufacturing mainly requires materials such as fibers, yarns, fabrics, and machinery specific to the industry. Steel round bars are more commonly used in construction, engineering, and manufacturing sectors where structural strength is required.

- Q: What are the applications of steel round bars?

- Steel round bars have a wide range of applications across various industries due to their inherent strength, durability, and versatility. Some of the key applications of steel round bars include: 1. Construction: Steel round bars are extensively used in the construction industry for various structural purposes. They are commonly used for building columns, beams, and frames due to their high strength-to-weight ratio, which ensures stability and safety in construction projects. 2. Manufacturing: Steel round bars are widely used in the manufacturing sector for fabricating various components and machinery. They are commonly employed in the production of gears, shafts, axles, and other machine parts that require high strength and precision. 3. Automotive industry: Steel round bars find significant applications in the automotive industry. They are used in the manufacturing of crankshafts, connecting rods, suspension components, and many other parts, providing strength and reliability to vehicles. 4. Oil and gas industry: In the oil and gas sector, steel round bars are used for manufacturing drill bits, valves, pipes, and other equipment that are exposed to harsh environmental conditions and require high strength and corrosion resistance. 5. Aerospace industry: Steel round bars are essential in the aerospace industry due to their high strength and lightweight properties. They are used in the production of aircraft components, such as landing gear, engine parts, and structural components. 6. Shipbuilding: Steel round bars are commonly used in shipbuilding due to their excellent strength and corrosion resistance. They are used in the construction of ship frames, hulls, and other critical components that require durability and resistance to harsh marine environments. 7. Infrastructure projects: Steel round bars are extensively used in infrastructure projects, such as bridges, tunnels, and railways. They provide the necessary strength and stability required for supporting heavy loads and ensuring the structural integrity of these projects. 8. Furniture and interior design: Steel round bars are also used in the furniture and interior design industry. They are commonly employed in the construction of chairs, tables, shelves, and other furniture pieces due to their sleek appearance, durability, and easy formability. Overall, steel round bars have a wide range of applications in various industries, contributing to the development of robust and reliable structures, machinery, and equipment.

- Q: How are steel round bars made?

- Hot rolling is the method used to produce steel round bars. It starts by heating a large rectangular steel billet until it becomes malleable. Then, the heated billet is fed through a series of rolling stands that gradually decrease its thickness and give it a round shape. To begin the hot rolling process, the billet is placed in a furnace and subjected to extremely high temperatures, typically ranging from 1200 to 1300 degrees Celsius. This high heat makes the steel more pliable and easier to manipulate. Once the billet is heated, it is introduced into a rolling mill. This mill consists of rollers that progressively reduce the thickness and elongate the billet. Each set of rollers squeezes and stretches the billet, gradually forming it into a round shape. The number of passes through the rolling mill depends on the desired final size and shape of the round bar. While the rolling process takes place, the steel bar is also cooled to prevent overheating and ensure proper metallurgical properties. This cooling can be achieved through the use of a water spray or air cooling system. After the bar has been shaped and cooled, it is cut into the desired lengths. The cut bars then undergo further processes, including straightening, surface treatment, and quality testing. These additional steps guarantee that the steel round bars meet the required specifications and standards. In conclusion, the production of steel round bars involves heating a steel billet, passing it through a series of rolling stands to shape it into a round bar, cooling it, and cutting it into the desired lengths. This process enables the creation of robust and long-lasting round bars that serve various applications in industries like construction, manufacturing, and engineering.

- Q: What is the maximum length of a steel round bar available?

- The maximum length of a steel round bar available can vary depending on various factors such as the manufacturing capabilities, transportation limitations, and customer requirements. However, in general, steel round bars can be produced in lengths ranging from a few feet to several meters. The specific maximum length will depend on the size and diameter of the round bar, as well as other logistical considerations. It is important to consult with steel suppliers or manufacturers to determine the maximum length available for a specific type and size of steel round bar.

- Q: Can steel round bars be cut to custom lengths?

- Indeed, it is possible to cut steel round bars to tailor-made lengths. These bars made of steel are adaptable and can be effortlessly cut using different techniques like sawing, shearing, or torch cutting. These approaches enable accurate adjustments to be made to meet specific demands or project necessities. Moreover, steel round bars are often obtainable in standard lengths, but they can be conveniently shortened or elongated by welding separate pieces together. All in all, steel round bars provide versatility in terms of length customization, rendering them suitable for a diverse array of applications.

Send your message to us

Hot Rolled Alloy Structural Steel Round Bar SCM440

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords