Air Cushion Belt Conveyor,New-Type Mining Equipment,Conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Profile

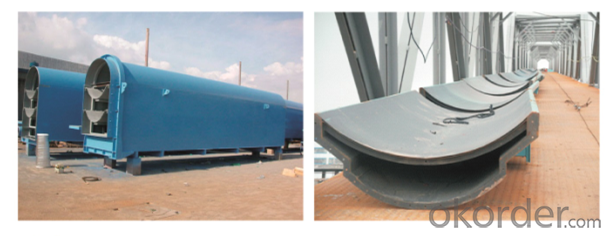

Air cushion belt conveyor is a kind of general series of products, which is widely used in coal, electric power, metallurgy, chemical industry, machinery, food, light industry, harbour, building materials and other industries. The transport system is combined with single machine or multiple conveyors to transport the all kinds of powdery material, granulous material and massive materials which density of all kinds of materials is less than 2500kg/m. Especially, it applies to transport the mixture material which is compounded to a scale. Also, it can transport the soft flexible package materials. The working environment of the air cushion belt conveyor is 25~~+40℃,generally. If the working condition is required, such as heat resistance, cold resistance, water proof, corrosion prevention, blast proof, inflaming retarding, the protection measurement should be took action. The transported materials include bulk material and package material. The transported particle size is decided by the width of the belt, the speed pf the belt, the groove angle of plate trough and inclination of conveying. Also, it is decided by the frequency of occurrence of chunk materials. In the meanwhile, the air cushion belt convey applies to those single light-weight and flexible package material which requires the lateral dimension should be small than width of the belt as 50-100mm. The unit area of the package material on the belt should be no less than 5kN/m2. The air cushion belt conveyor can be used in horizontal, inclination upward or downward transportation.

As a kind of new-type deep-trough belt conveyor which can realize the large transport capacity. The air cushion belt conveyor can apply air cushion to replace the roller bearing and change the rolling friction of supporting roller belt conveyor into fluid friction, as a result, it has reduced the tractive forces of driving device and the operation resistance of belt conveyor. Meanwhile, when there are the same transport capacity and conveying process, the power consumption is saved for 15~30% than the supporting roller belt conveyor.

Air cushion belt conveyor is a kind of belt conveyor that the belt of conveyor and the materials on the belt is supported and transported by thin gas film. What’s the structure of the air cushion belt conveyor is that the carrier roller of the roller belt conveyor is replaced by the foraminiferous cushion slot. When the source of the air provides quantitative of stress and the flow of air, the air in the cushion slot will spill out across the small hole in the plate trough. It shapes a layer of gas film with stress to support the belt of air cushion belt conveyor and the materials on the belt. The supporting of carrier roller set at a certain distance is replaced by supporting air cushion, which changes the rolling friction between carrier rollers in the belt into fluid friction between the conveyor belt and plate trough. The medium of the fluid friction is air. It can decrease the running resistance. Also, it has many advantages.

Performance feature

It has increased 5% loading sectional area, as a result, the transport capacity is increased for 15% and upward transport energy on the inclined slope is saved for 5%~12%。

It has small operation resistance and high stability, what’s more, which can prolong the service life of conveyor belt for 3-4times, and save 80% repairing expense.

It is unnecessary to install the sealed conveyor corridor for the full air cushion conveyor, as a result, which can save 35% investment expenses in the infrastructure.

Application prospect

Like general belt conveyor, the air cushion belt conveyor is widely used in coal, metallurgy, chemistry industry, electric power, building material, food, harbour, mine and all departments in factory to convey all kinds of bulk material. The air cushion belt conveyor has been used in coal and harbor firstly. Then, it has been gradually used in steam supply and power generation plant, cement mill, flour mill, feed mill, chemical fertilizer plant, chemical plant, steel mill, glass mill, pharmaceutical factory to transport coal, cement, food, chemical fertilizer, mineral and other bulk material and bagged cargo. In recent years, the advantages of the air cushion belt conveyor has been aware of. And the level of design and manufacturing has been enhanced. The using of the air cushion belt convey has become more and more common. In order to prevent the environment from polluting and the prevent the quality of the material from polluting by the environment, the enclosed transporting line adopts air cushion belt conveyor.

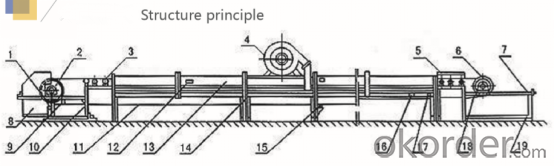

Structure principle

1. Driving device 2. Transmission cylinder 3. Trough carrier roller 4. Draught fan 5. Feed channel 6. Redirection cylinder 7. Spiral tension device 8. bow cap 9. Rotary controller 10. head stock 11. adhesive belt 12. peep door 13. Enclosed fitting 14. Gas tank splice

15. Below flat idler 16. Cord switch 17. Dead band swabbing pig 18. Drive end unit frame 19. Stern roll

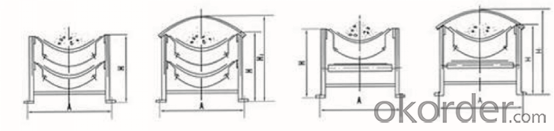

Sketch

1. Full air cushion open type 2. Full air cushion leak tightness 3. Mixture open type 4. Mixture leak tightness

Delivery value of air cushion belt conveyor

Bulk density of materials (kg/m3) | Width of belt(mm) | |||||

500 | 650 | 800 | 1000 | 1200 | 1400 | |

500 | 39 | 72 | 113 | 183 | 270 | 374 |

800 | 63 | 115 | 181 | 293 | 432 | 599 |

1000 | 79 | 143 | 226 | 367 | 540 | 748 |

1200 | 95 | 172 | 272 | 440 | 648 | 898 |

1600 | 127 | 220 | 362 | 586 | 465 | 1197 |

2000 | 158 | 287 | 453 | 733 | 1081 | 1496 |

2500 | 198 | 359 | 566 | 916 | 1351 | 1870 |

Notes: Therein, the maximum transport capacity Q(its unit:t/h) as specified in the table is calculated when the belt width B and stacking density ρ of materials are available, and the belt speed V, the inclination factor k, the run stacking angle of materials 0 and the plate trough angle λ are 1.0m/s, 1.0, 25 and 30°respectively.

FAQ:

What’s the used air cushion plate trough is made of ?

Commonly, it is made of Q235 cold-roll steel sheets; For special purpose, it also can be made of stainless steel.

What’s the pattern of arrangement form of air cushion belt conveyor?

The pattern of the arrangement form includes: horizontal arrangement, overall inclined arrangement, concave-convex arrangement( match with carrier roller)

Whether if it is convenient to maintain?

The whole course will use less carrier roller group and less quantity of maintenance.

Send your message to us

Air Cushion Belt Conveyor,New-Type Mining Equipment,Conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches