Agru Geomembrane Geocomposite for Landfill Wastewater Prevention

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

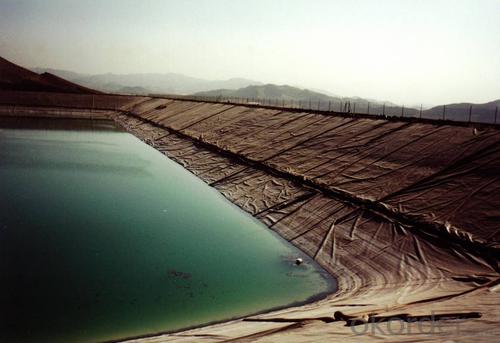

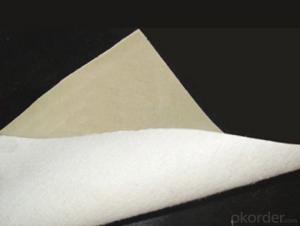

Structure of Geocomposite Membrane for Landfill

Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the full range of specifications and low cost, simple construction.

Main Features of Geocomposite Membrane for Landfill:

Environmental Engineering: Landfill,Sewage treatment plant, Electric plant regulating reservoir, Hospital solid waste, etc.

Hydraulic Engineering: Canal waterproof, Dam leaking stoppage, reinforcement, Vertical core, Slope protection, Revetment, etc.

Municipal Engineering: Tunnel, Subway, Planted roof, Roof garden,Sewage conduit lining, etc.

Gardens Engineering: Artificial Lake, Watercourse, Impounding reservoir, Golf course pond lining, Lawn waterproof, etc.

Geocomposite Membrane for Landfill Images

Geocomposite Membrane for Landfill Specification :

No. | Item | Test Value | |||||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | |||||

1 | Minimum Density(g/cm³) | 0.939 | |||||||||

2 | Tensile Property | ||||||||||

Yield Strength ,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||||

Break Strength ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | ||||

Yield Elongation ,% | 12 | ||||||||||

Break Elongation ,% | 700 | ||||||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | |||

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | |||

5 | Stress Crack Resistance, hrs | 300 | |||||||||

6

| Carbon Black | ||||||||||

Carbon Black Content, % | 2.0-3.0 | ||||||||||

Carbon Black Dispersion | Carbon black dispersion(only near spherical agglomerates) for 10 different views 9 in categories 1 or 2 and 1 in category 3 | ||||||||||

7

| Oxidative induction time(OIT) | ||||||||||

Standard OTI Min | 100 | ||||||||||

High Pressure OTI Min | 400 | ||||||||||

8 | Oven aging at 85℃ | ||||||||||

Standard OIT-% retained after 90 days | 55 | ||||||||||

High pressure OIT-% retained after 90 days | 80 | ||||||||||

9 | UV Resistance | ||||||||||

Standard OIT retained after 1600 hrs | 50 | ||||||||||

High pressure OIT retained after 1600 hrs | 50 | ||||||||||

10 | Low tempreture impact brittle property at -70°C | Pass | |||||||||

11 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | |||||||||

12 | Dimensional Stability (%) | ±2 | |||||||||

FAQ:

1. How about the delivery time?

Two weeks upon receipt of down payment.

2. What kind of payments do we accepted?

T/T, L/C, WesternUnion, MoneyGram.

3. What's are the MOQ?

Normally the MOQ is 5000 SQM in theory.

And we can provide you free samples for quality inspection.

4. Do you charge for the samples?

Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee in your second order.

5. Can you produce the product according to customers' requirements?

Sure, we are professional manufacturer, OEM and ODM are both welcome

- Q: Is high density polyethylene geomembrane the same as drain board?

- These two kinds of geotextile materials are different in application and nature.

- Q: How is electric heating film electric heating

- It is good and more environmental friendly! And have a good quality

- Q: Which kind of the mobile phone screen protector brand is better?

- There are all kinds of mobile phone protection film brand. In general, everything has own value. Since you want to paste film, you'd better paste a reliable brand to save some trouble later. The best choice is the film with static electricity and absorption technology,

- Q: Which mobile phone film is better? film or epidural?

- The film must be tempered or film, because the average hardness of the film is not mobile phone screen, the hardness is not enough not to protect, and the film is easy to draw, cause the screen light not. Toughened film hardness but with slightly larger screen is almost the same, but also posted a protective effect, but the film will affect the transmission is easy to leave fingerprints, the screen will dirty so or not to consider the film paste to paste, paste the best tempered film

- Q: How to pave the electrothermal?film?

- Attention should be paid to several aspects when paving ceramics on electrothermal?films: first, is waterproof insulation should deal be well prepared; second, the concrete used to pave ceramics should not be too thick. The thickness should be controlled within 50mm (the thickness of concrete and ceramics, such thickness is convenient for heat transfer); third, expansion joints of ceramics must be retained(because floor heating system will lead to heat expansion and cold contraction); fourth, the temperature increases slowly which avoids expansion caused by excessive heat; fifth, the electrothermal film power should be controlled within 80W/square meter in accordance with the room size; sixth, load must be calculated before the installation of temperature controller so as to avoid the line fault of temperature?controller; seventh, phase line must be allocated reasonably in accordance with the inlet wire of the room(now the inlet wire uses three-phase four-wire system) so as to save energy, electrothermal film input lines in several rooms should be separately connected to inlet wire, and single-phase overload should be avoided. Remarks: Electrothermal membrane belongs to safety facilities, so the quality of products is in the first place(good quality of electrothermal film, high temperature resistant power line, multi-strand wires and joints should be welded, insulation treatment should be carried out after welding, and luted with glue) and construction quality is in the second place, consider, it should be no risk at all.

- Q: What is the construction technology of the color permeable concrete project?

- 1. To grind surface and use professional grinding machine polishing on the surface of the base, surface laitance, dust cleaning, open the original surface voids and make concrete seal curing agent could be fully penetrated 2, clean up the surface to be polished produced in the process of dust, the dust cleared off. 2. To clean up the surface: The dust produced in the process of polishing should be cleaned off. 3. To spray the concrete sealed curing agent and spray the concrete seal curing agent on the ground, and use the dust drag for uniform treatment. Let material response 2-4 hours. When the surface becomes sticky, you can go on the next step. 4. To clean the surface and water to flush the concrete seal curing agent material overflow part of the flushing reaction. To prevent the residue turn into white. 5. The water polishing. To polish the ground to further enhance the density of the ground surface, and show the mirror effect. 6. To clean the ponding, the remaining water should be cleaned after the water polishing. 7. The polishing of the concrete sealed curing agent, and install the resin polishing pad with the polishing machine, making a further polishing of the ground. 8. The completion display of the concrete seal curing agent .

- Q: How are geomembranes tested for chemical resistance?

- Geomembranes are tested for chemical resistance through a series of laboratory tests. These tests typically involve exposing the geomembrane material to various chemicals commonly found in the environment and assessing its performance. The geomembrane samples are subjected to different concentrations and temperatures of the chemicals for a specific duration. After exposure, the samples are evaluated for any signs of degradation, such as changes in physical properties, color, or structural integrity. The results of these tests help determine the suitability of the geomembrane for specific applications where chemical resistance is crucial.

- Q: Geomembrane is used for anti-seepage system which layer structure? What are the materials for the anti-seepage system?

- Cement concrete above, but impervious material on the 30 cm or so to protect the layer, so as to ensure that the geomembrane waterproof seepage better!

- Q: How to construct the bottom of geomembrane oil tank?

- Construction of oil tank is more troublesome, and it should comform to construction drawings. There are professional welders and welding equippment, you may start weld after pavement.

- Q: Generally, how many welding rods are needed when welding the impoted geomembrane of ten thousand square meters?

- I can not tell you precisely how many welding rods are needed as it is related to the terrain of your project, soil environment, and design. Based on simple estimation, it seems that 35 or 36 kilograms of rods are needed.

Send your message to us

Agru Geomembrane Geocomposite for Landfill Wastewater Prevention

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords