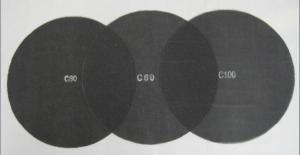

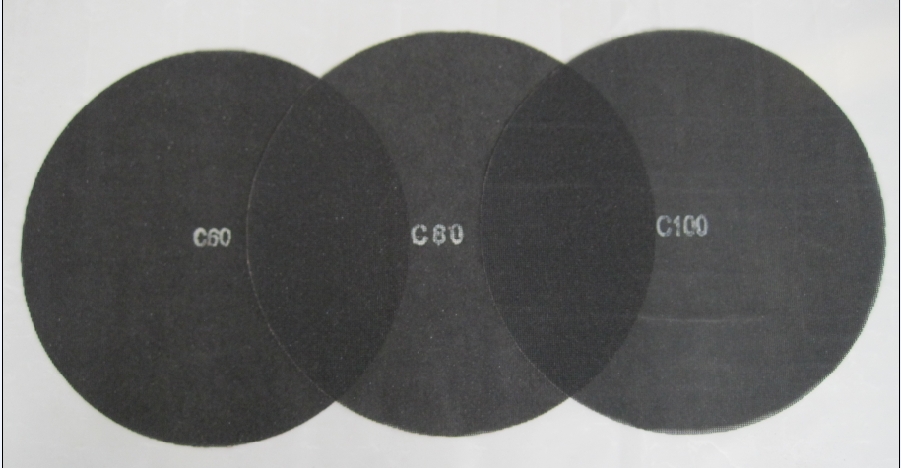

Abrasive screen —C60#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Abrasive sanding mesh screen is made of nylon fabric, coated with

abrasive materials; there are three kinds of shape: Sheets, Discs and

Rolls.

It is not only suitable for sanding plaster and wall surface, but also for

sanding rusty spots of metal materials and making grinding and

polishing treatment. It has good

properties of grinding, cutting and filings

removing. And it is the most ideal

abrasive tool for interior decoration.

- Q: Are there any specific training or certification requirements for using steel tube couplers?

- Steel tube couplers necessitate specific training and certification. In numerous sectors, including construction, scaffolding, and engineering, individuals handling steel tube couplers must complete specialized training and acquire relevant certifications. These training programs generally encompass topics such as the correct installation and inspection of couplers, comprehension of load capacities, and adherence to safety protocols. Certification is typically obtained through reputable industry organizations or regulatory bodies, serving as evidence that an individual possesses the requisite knowledge and abilities to use steel tube couplers safely and effectively. Adhering to these requirements is crucial to guarantee the structural integrity and safety of any project involving steel tube couplers.

- Q: Can a waterproofing membrane be used for a residential building?

- Yes, a waterproofing membrane can be used for a residential building. A waterproofing membrane is a thin layer of material that is applied to the exterior walls, foundation, or roof of a building to prevent water from penetrating into the structure. It acts as a barrier against moisture, preventing water damage and mold growth, and can also help to improve the energy efficiency of the building by reducing heat loss. In a residential building, a waterproofing membrane can be used in various areas such as basements, bathrooms, balconies, roofs, and exterior walls. It is particularly useful in areas that are prone to water infiltration, such as basements where groundwater can seep in, or bathrooms where water splashes and steam can cause moisture issues. There are different types of waterproofing membranes available, including liquid-applied membranes, sheet membranes, and self-adhering membranes. These membranes are designed to be durable, flexible, and resistant to water, ensuring long-lasting protection for the residential building. By using a waterproofing membrane, homeowners can safeguard their property from water damage, structural issues, and health hazards associated with moisture intrusion. It is important to consult with professionals to determine the specific type of waterproofing membrane that is suitable for the residential building based on the location, climate, and potential sources of water infiltration.

- Q: I would like to be a multi-purpose cabinet, I do not know what kind of good plate, please master master guide, thank you

- The most light, the most environmentally friendly, so beautiful and practical man-made sheet is ecological wood.

- Q: Tableware kitchen, epoxy resin can? Specific paint name and processing process, thanks for the

- The cement board is prefabricated and also cast

- Q: I have tried draino, but I think I need to pull out the drain and remove the hair and stuff. It drains really slow. I don't know if I should call the landlord because it is something small. But I don't know how to remove the drain. do I just pull it straight out? there are no screws or anything, but it doesn't seem to want to budge and I don't want to break it since it isn't really mine. here is a picture of the type of drain I am talking about:http://upload.wikimedia.org/wikipedia/commons/3/3b/Bathroom_sink_drain.jpg

- there is a very handy little tool that you may be able to remove enough of the hair and then the rest will probably flush down. Menard's or home depot have them. It is about 30 inches long and 1/2 inch wide.has sharp little hooks on each side.just run it down into the drain opening up & down, it will hook on to the hair and you can pull it out.do it until you get no more hair. then run hot water down the drain no need to disconnect the trap unless you have more than just hair in the trap Good luck

- Q: What are the environmental impacts of using geogrids?

- The environmental impacts of using geogrids can vary depending on factors such as the type of material used, manufacturing processes, and disposal methods. However, some potential impacts include the extraction of raw materials, energy consumption during manufacturing, and the generation of waste and emissions. It is important to consider these factors and ensure proper management and disposal practices to minimize the environmental impacts of using geogrids.

- Q: Imitation copper paint are sunscreen it?

- First, metal copper ????- element symbol Cu, atomic weight 63.54, specific gravity 8.92, large capacity 1083 °. ????- pure copper was light rose or light red, the surface of the formation of copper oxide film, the appearance of copper. Copper physical and chemical properties: good thermal conductivity and conductivity, chemical stability, tensile strength, easy to weld, with corrosion resistance, plasticity, ductility and so on. - The appearance of copper is red, and it is also recognized as a green metal (durable, recyclable and re-use and copper elements are animal and plant and human health, survival indispensable trace elements). ????- Copper is one of the ancient metals used by mankind. Has now been widely used in electrical appliances, light industry, machinery, construction, defense and other fields, and into the modern living space, copper doors, windows, handicrafts, roofs, awnings, lamps and so on. , ????- Copper products because of its deep artistic and cultural heritage, environmental protection, corrosion resistance, durability, antibacterial, applicability, etc. can be widely used. As the new copper door, window product, it is widely used in financial system, hotel hotel, business, clubhouse, office area and high-end villa, district and so on.

- Q: What kind of heater? Home electric heater how to choose

- Home heating or the use of electric heating is good, like a small sun to the fast, but no heat.

- Q: How can one efficiently and safely remove used aluminum foil from food items after cooking or storing?

- <p>The best way to remove aluminum foil facing from food after use is to carefully lift the edges of the foil with a pair of tongs or a fork, ensuring not to touch the food directly with your hands. Gently pull the foil away from the food, starting from one corner and working your way around. If the foil is stuck, use a butter knife or a spatula to gently separate it from the food. Be cautious not to tear the foil, as this can create sharp edges and make removal more difficult. Always dispose of the used foil properly in a trash receptacle.</p>

- Q: What are the common maintenance practices for steel formwork?

- To ensure the steel formwork's optimal performance, various maintenance practices should be followed. These include regular cleaning and inspection, lubrication of movable parts, repair of any damage or wear, and appropriate storage when not in use. To maintain cleanliness, it is crucial to remove any concrete residue, dirt, or debris that may accumulate on the formwork. This can be achieved by using water, a mild detergent, and a stiff brush. Caution should be exercised to avoid abrasive materials or chemicals that may harm the steel. It is necessary to conduct routine inspections to identify signs of wear, damage, or corrosion. This should be done both before and after each use of the formwork. Any cracks, deformations, or loose parts should be promptly repaired or replaced to ensure the formwork remains safe and functional. Lubricating moving parts, such as hinges, locks, and adjustable components, is of utmost importance to guarantee smooth operation. Applying a suitable lubricant to these parts helps prevent rust, corrosion, and sticking. This practice helps maintain the formwork's functionality and ease of use. Repairing any damage or wear is vital to uphold the structural integrity of the formwork. Swift action should be taken to repair any cracks or deformations using appropriate methods like welding or reinforcing. Damaged parts must be replaced with new ones to uphold the formwork's strength and stability. Proper storage is essential to prolong the lifespan of steel formwork and prevent damage. It should be stored in a dry and well-ventilated area to avoid corrosion. Additionally, formwork should be stacked or stored in a manner that prevents distortion or bending of the steel components. Furthermore, protecting the formwork from moisture and excessive heat is crucial to avoid potential damage. By adhering to these common maintenance practices, the steel formwork can be preserved in excellent condition, ensuring its durability and reliability for future use.

Send your message to us

Abrasive screen —C60#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords