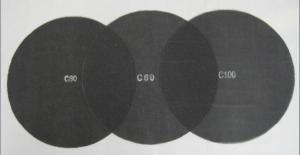

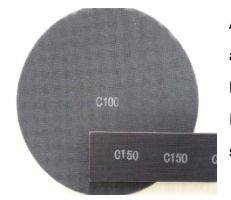

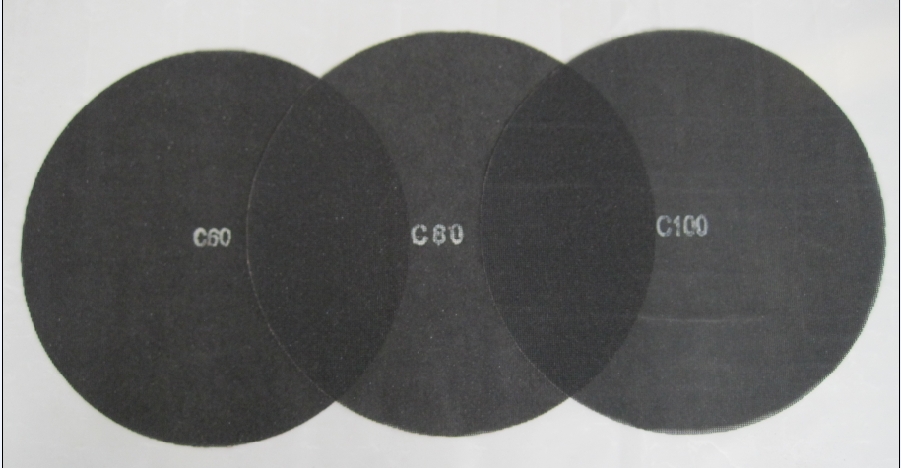

Abrasive screen —C600#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Abrasive sanding mesh screen is made of nylon fabric, coated with

abrasive materials; there are three kinds of shape: Sheets, Discs and

Rolls.

It is not only suitable for sanding plaster and wall surface, but also for

sanding rusty spots of metal materials and making grinding and

polishing treatment. It has good

properties of grinding, cutting and filings

removing. And it is the most ideal

abrasive tool for interior decoration.

- Q: Are sandwich panels suitable for automotive showrooms?

- Sandwich panels are an ideal option for automotive showrooms. Comprised of two outer layers or skins with a lightweight core material in between, these panels offer exceptional strength and insulation qualities. They are versatile and can be utilized in various ways, including building facades, partitions, and interior walls. Within automotive showrooms, sandwich panels can be employed to construct walls, ceilings, and even floors. They bring numerous advantages that make them perfect for this setting. Firstly, they provide excellent insulation, ensuring a comfortable temperature inside the showroom regardless of external weather conditions. This is crucial for creating a pleasant atmosphere for both customers and staff. Moreover, sandwich panels are lightweight and easy to install, allowing for efficient and fast construction. This is advantageous for automotive showrooms, as they often face tight deadlines and need to become operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, offering flexibility in creating unique and appealing showroom layouts. Additionally, sandwich panels possess excellent noise reduction qualities, guaranteeing a quieter environment within the showroom. This is significant in providing a comfortable ambiance for customers and enabling them to focus on the showcased vehicles. Furthermore, sandwich panels are durable and require minimal maintenance. They are resilient against corrosion, moisture, and fire, providing a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for the incorporation of branding and aesthetic preferences into the showroom design. In conclusion, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They offer a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q: Is it possible to utilize black fiberglass tissue to create insulation materials for residential buildings?

- <p>Yes, black fiberglass tissue can be used for making insulation materials for houses. Fiberglass, including its black variant, is a common material used in insulation due to its ability to resist heat transfer, providing thermal insulation. It is also known for its durability and resistance to moisture, which makes it suitable for various insulation applications in residential construction. However, it's important to note that proper handling and installation are necessary to ensure safety and effectiveness, as fiberglass can cause skin and respiratory irritation if not managed correctly.</p>

- Q: Hey guys, so I got my scaffolding (ear) done yesterday. My piercer told me NOT to clean it, and that the best thing for a cartilage piercing is to quot;leave it bequot; I trust this advice, but I wanted to ask your opinion or methods that worked for you :) Thanks lt;3

- nonono, industrials or notorious for infections. if you don't clean it, imagine how much bacteria is going to be near it since all the folds of the ear and the oils or your hair. I clean my industrial at least twice daily, and I have yet to get an infection though. What I do is Sea Salt Soaks in the morning and night. I put a little emu oil to advoid hypertrophic scarring. and I have kept my hair up every day since getting it pierced to make sure my hair doesn't irritate it while its still in its early healing phase.

- Q: Golf 7 in the control cup on the round is what things

- Is an ashtray, if no smoking can be a storage box

- Q: Our original home is the height of the beam is now 3m to 2.6 of the beam is not to the bridge before the support leg height

- The front leg is to reduce a certain height. Do not know who you are using the bridge machine, and some of the front legs of the bridge machine can be dismantled section, and some have spiral support, so, but also with the design manufacturers, can not change their own. Once you have it, in case of any problems, the designer has no responsibility.

- Q: Is a waterproofing membrane resistant to punctures or tears?

- Yes, a waterproofing membrane is designed to be resistant to punctures and tears. It is specifically engineered to provide a durable barrier that can withstand potential damage from sharp objects or external forces.

- Q: Aluminum alloy door with stainless steel door that is better?

- Not much. Aluminum can be beautiful

- Q: Has adjusted the pressure behind the buttocks screws, in front of the adjustment screw and the card before and after the tune, Guiqiu how to get the door closet in the door when the big open does not automatically shut down, move the point angle will automatically shut down?

- Turn on the door shutters after turning on the auto stop function. Door closers are mainly used in commercial and public buildings, but are also used at home. They have many uses, the most important of which is to make the door closed by itself, to limit the spread of fire and ventilation within the building.

Send your message to us

Abrasive screen —C600#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords