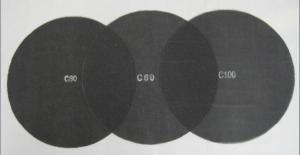

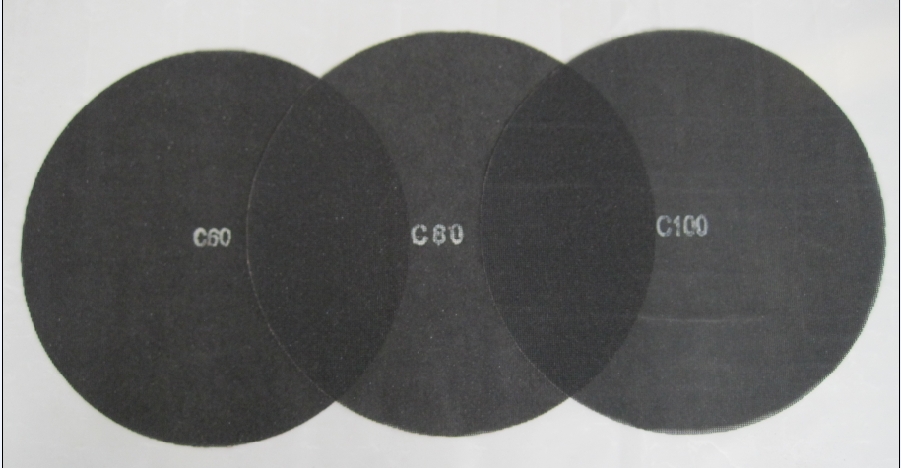

Abrasive screen —C200#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Abrasive sanding mesh screen is made of nylon fabric, coated with

abrasive materials; there are three kinds of shape: Sheets, Discs and

Rolls.

It is not only suitable for sanding plaster and wall surface, but also for

sanding rusty spots of metal materials and making grinding and

polishing treatment. It has good

properties of grinding, cutting and filings

removing. And it is the most ideal

abrasive tool for interior decoration.

- Q: China, how can sell aluminum plastic plate, it is best to have a number of stores can be compared, the thickness is about 2-3MM, the price in general how much? Advertising light box

- If you do light boxes, you can purchase some of the 150 or so has been enough to use. 2 mm board material should be priced at around 100 yuan, too cheap also, but the quality has not guaranteed the basic needs.

- Q: How are steel formwork panels connected together?

- Steel formwork panels are connected together through a variety of methods to create a strong and stable structure for concrete pouring. One common method is the use of steel pins or bolts, which are inserted into pre-drilled holes in the panels. These pins or bolts are then tightened or fastened with nuts, ensuring a secure connection between the panels. Another method is through the use of clamps or couplers, which are placed around the edges of the panels and tightened to hold them together. These clamps or couplers can be easily adjusted or removed, allowing for flexibility in the formwork system. Additionally, some steel formwork panels feature interlocking mechanisms, such as slots or hooks, that enable them to be easily aligned and connected. These interlocking features provide a seamless connection between the panels, creating a smooth and continuous surface for concrete placement. Overall, the connection of steel formwork panels is crucial for maintaining the integrity and stability of the formwork system during the concrete pouring process. The chosen method of connection will depend on the specific design and requirements of the project, as well as the type of steel formwork being used.

- Q: i was at a consignment shop and i bought this dressbin/dynamic/product.cgi?frame=main&size=3&floatsize=3&style_number=7405292&color=RICHPLUMin the plum colour and i don't know how to wash it because the washing "recommendations" tag was cut out the website says that the dress is 85% cotton and 15% cashmerecan you reccommend how to wash it??

- I would wash it in cold and then reshape and lay flat to dry. If you have any doubts dont hesitate to take it to a dry cleaners and they can either clean it for you or tell you what to do

- Q: Our concrete slab for the porch was poured after the house was built and concrete was splattered on a door. How do we go about removing it without damaging the paint? Sandy :O)

- Muriatic acid will do the trick. You can get it at most pool supply or hardware stores. Just pour some in a pail and dip a sponge or paint brush in and wipe it on the splatters. You may have to scrub a little but it will take off the cement. Don't forget to use gloves and make sure the area is well ventilated. The fumes can damage your nasal passages and lungs.

- Q: Is it ok to have a black bathroom vanity with brown wall trim?

- If you like it that is all that matters. You did not say what the over all colors were in the bathroom. ()

- Q: How do right-angle couplers work in scaffolding?

- Right-angle couplers play a vital role in scaffolding systems by connecting two perpendicular tubes at a 90-degree angle. They ensure stability and strength in the scaffolding structure. The working principle of right-angle couplers is simple. They consist of a body and a bolt. The body has two open ends that fit perfectly around the tubes, and the bolt secures the tubes together when tightened. To use a right-angle coupler, insert the tubes into the open ends of the body. Then, insert the bolt through the body and tighten it with a spanner or wrench. This action creates a firm connection between the tubes. One important aspect of right-angle couplers is their ability to grip the tubes securely. Teeth or serrations on the inside surface of the body bite into the tubes when the bolt is tightened, preventing slippage or movement. Right-angle couplers are designed to resist shear forces, which occur when perpendicular tubes try to slide against each other. They maintain the stability of the scaffolding structure. In addition to connecting tubes at right angles, right-angle couplers allow for flexibility in scaffolding design. They enable the construction of various configurations, enhancing the versatility and adaptability of the system. Overall, right-angle couplers are essential components in scaffolding systems. They provide a secure and stable connection between perpendicular tubes, ensuring the safety and strength of the structure in the construction industry.

- Q: How much of the acceptance of gravel material is an inspection lot

- Raw material acceptance inspection lot is generally according to the number of sand and gravel inspection shall prevail, a project inspection once to do once on the line.

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- Both are their own strength, stiffness is not high, the turnover rate of the template material is low, but the cost is relatively low, due to different uses, can not be compared: wood sheet low cost, can be processed, the turnover rate is low, can not help blisters, if Small keel spacing is large, and the concrete side of the larger pressure, its own stiffness is low, there will be bending deformation or even up the mold, generally in the base floor or slope roof and other concrete appearance quality requirements are not high or one-time no longer a lot of turnover Parts of the use of plastic templates are generally stereotypes, such as ribbed floor in the plastic mold shell, is a specific structure with the template can be leased.

- Q: How to deal with the plastic foam on the floor?

- How to deal with the plastic foam on the floor?

- Q: Geotechnical deployment of aging detection of what indicators

- Material anti-aging performance testing, if the reality to consider, for too long, are generally used in the laboratory to accelerate the aging approach to consider. Aging the concept of aging is a big concept. Refers to the material in the external environment under the influence of time changes. Environmental effects are multifaceted, the role of light, the role of temperature, a chemical role, the role of micro-organisms and so on. Now generally referred to as aging, refers to the light aging. Light aging, refers to the material in a certain light exposure after a certain period of time after the performance of the material changes. The most commonly used indicator for photoaging is the strength retention of the material. That is, the ratio of the strength that remains after the light is retained.

Send your message to us

Abrasive screen —C200#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords