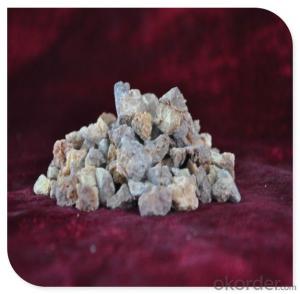

97% FM Fused Magnesite Raw Materials for High Quality Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | 1MT (1.25MT) jumbo bags, Or according to customers' requirements |

| Delivery Detail: | Within around 20 work days based on MOQ |

Product Description of White Fused Magnesite :

Fused Magnesite (Ordinary Grade) is manufactured through fusing high quality raw magnesite in electric arc furnace with the characteristics of big crystal, dense structure and strong corrosion resistance.

| Brand | Physical and chemical indices | Size | ||||||

| MgO | SiO2 | CaO | Fe2O3 | Al2O3 | 1gL | B.D≥ | (mm) | |

| ≥ | ≤ | ≤ | ≤ | ≤ | ≤ | (g/cm³) | 0-30, 0-60 | |

| WFM-99 | 99 | 0.15 | 0.4 | 0.25 | 0.1 | 0.1 | 3.5 | |

| WFM-98.5 | 98.5 | 0.3 | 0.7 | 0.3 | 0.15 | 0.1 | 3.5 | |

| WFM-98 | 98 | 0.35 | 1 | 0.4 | 0.2 | 0.1 | 3.5 | |

| WFM-97.8 | 97.8 | 0.4 | 1 | 0.5 | 0.2 | 0.1 | 3.5 | |

| WFM-97.5 | 97.5 | 0.5 | 1 | 0.55 | 0.2 | 0.15 | 3.5 | |

| WFM-97 | 97 | 0.6 | 1.2 | 0.7 | 0.2 | 0.2 | 3.5 | |

Packaging & Shipping of White Fused Magnesite :

Packaging: 1.25MT jumbo bags or 1MT jumbo bags

Delivery details: according to customers’ requirements

Application of White Fused Magnesite :

Used for lining the high-feequency induction furnace to make the special alloy steel and for producing the crucibles, which are also super insulating materials

Advantages:

1) We have subsidiary plants doing metallurgical materials;

2) For some product, we do trading, while we can control the quality and cost due to our strong capacity and cash flow in China;

3) Our logistics and freight charge is lower than others since we have big quantity cargo to be exported in some main ports China;

4) We have strict and mature quality and logistics control on the cargo;

5)As a governmental company, we are reliable

The following are part of the products and loading process pictures,Pls kindly note,Thank you.

- Q: How many kinds of refractory materials are there in the EI?

- I suggest that you contribute articles to foreign SCI journals for the odds are better, and generally the articles that fill the bill will not be rejected. The traditional refractory materials can contribute to EI journal. If being rejected by EI journal, you can also contribute to Russia's journal Industrial Ceramics and Refractories. I didn't contribute to the Journal of Wuhan University of Science and Technology, the receiving cycle is almost 3 to 4 months. Though the impact factor is low, domestic EI journal is not so good, it is still SCI journal. This is my own experience, please take my advice. The best journals are the Journal of the American Ceramic Society and the Journal of the European Ceramic Society, I heard that they are not bad. But the best domestic EI refractory material journal is the Journal of The Chinese Ceramic Society. It is very long, but if it belongs to your university, it is another pair of shoes. Journals now all want to have materials about functional ceramics, and they don't want Chinese articles, if your English is not well enough, you can choose Ceramics International and Japan Ceramics but they have strict manuscripts reviewing standards.

- Q: How is the grading of the level A new material fire insulation material?

- The standard to distinguish level A and level B is the different fireproofing coefficient. The level A is non-combustible. The level B is divided into B1, B2 and B3. B1 is flame retardant, B2 combustible and B3 flammable. The level A is commonly phenolic aldehyde, rock wool, thermal?mortar, foam ceramics, foam glass and foam concrete on the current market. Among the advantages of level A materials, the biggest one is foam concrete currently, also known as foam cement, which the Xuzhou Green Year EEB company's main produces.

- Q: how about the performance of aluminum silicate fire proof thermal insulation?

- aluminum silicate fire proof thermal insulation board has a good performance. it is a artificial board that separates the wood and plant fiber by mechanical and chemical methods and mixed the adhesion agent and water-proofing?agent, molding by high temperature and high press. the density of fiber. tha above information is coming from the Internet and it is just for reference.

- Q: which kind of material should be used in fireproofing cabinet?

- Natural stone,marble. advantage: Colorful, soft texure, natural and diverse texture, easy to cut or engraving molding. Disadvantages: Because it is a natural formation, tiny loose crackle is easily folded, because the stone is porous material structure, if sewage and waste water permeate in the structure in the process of production, transportation or construction, it's difficult to clean and easy to crack. In daily cleaning, it is inevitable that there will be some residue left, and dirt is filled into crack under the wiping of rag and becomes a breeding ground for bacteria. 2, granite. advantages: Granite has big density and high hardness, with wear-resistant surface, it's one of the most common materials for family decoration. Compared with natural marble, it can be used in the materials of kitchen countertops, and granite has good anti-bacterial regeneration ability. Disadvantages: As the cabinet table material, natural stone is usually not very long, so in order to produce a long overall table (especially U-shaped, L-type table), it will certainly exist joints, which are also easy to hide dirt. 3, artificial stone. advantages: Artificial stone has richful lines and colors, and it can be comparable to stone, it's non-toxic, non-radioactive, easy to clean, and can be truly seamless splicing. it belongs to economic environmentally friendly material. Disadvantages: Artificial stone belongs to the processing industry, and has low technology requirements, The inferior products of many small companys are fulled in the market and damage customers' interests. There exist faded color,poor aging resistance,oil stain and other issues in affordable products.

- Q: Why do magnesium oxide refractory bricks can be made into refractories?

- The substance used in refractories must have the following characteristics and properties: 1, High stability: Anti-oxidation, anti-reduction and thermal decomposition; 2, High melting point of 2800 degree; 3, Low price. The magnesium oxide refractories have all these three characteristics and properties, particularlly in the aspects of melting point and stability .

- Q: Who knows that among refractory materials, insulation boards from which refractory material industry is superior in quality?

- Using high temperature insulation material during casting process .In the molding, assembly the insulation?board on the ingot head or install heat insulation cap . There are three ways to install the molded steel insulation board and install insulation?board on at the head of the ingot, namely, clamping, nail fixation and mosaic technique.Compared with clay-based liner, the use of insulating board will improve high steel billet rate up to about 5% to 10%.

- Q: Who knows about the fire endurance of grade C fire doors?

- The fire endurance of grade C fire doors is no less than 0.5 hours. As the key role of family fireproofing, fire doors is particularly important. It can be classified according to the fire endurance and thermal insulation performance: The fire endurance of grade A fire doors is not less than 1.5 hours; that of grade B fire doors is not less than 1.0 hours; and that of grade C fire doors is not less than 0.5 hours. The most important property of fire doors is the fire resistance period.

- Q: What are the construction fire-proof materials?

- 1. fire?retardant?coating 2. fireproof?panel 3. fire proof and sealing material 4. flame resisting decorative materials 5. Green fire prevention materials

- Q: who knows the technology of fireproofing material?

- First: Firstly, you should produce the recipe and prepare the raw materials, for example, if you prepare to produce 1 ton, you should compute the recipe sheet of 1 ton producing; check whether the raw materials are complete; second: make the color and filler thick liquid; add water in order and proper auxiliary in a low speed, then put color and filler (generally we should firstly add something with large oil absorption), wash the meachine after putting the powder. Then seperate them for about 20 miutes in a high speed, until the fineness is qualified; of course, if you need sander, i think you only need sino-soviet differential powder material and non-obvious particles. Third: Paint mixing period: after making the color and filler thick liquid, reduce the roll speed into about 600 roll per minute, add emulsion and proper auxiliary, finally adjust PH and viscosity. Liquid solvent paint, pigment paste: Resin,solvent and pigment ---〉pre mixing---〉stick---〉grinding--〉stick--〉packaging, highlight varnish: Resin, solvent ----〉mixing ----〉stick ----〉packaging, sub-gloss varnish: Resin, solvent----〉mixing----〉matting agent,stick----〉packaging, colored?paint: The primary colorant----〉Color matching by auxiliary color paste----〉stick----〉packaging, aluminum?paint: Aluminite powder soaking----〉resin----〉colour modulation, lustre adjusting----〉stick----〉packaging, powder coat: Resin,filler,pigment,auxiliary---〉mixing---〉extrusion---〉cooling---〉smashing---〉sieving---〉 packaging.

- Q: Are there any differences between insulation and refractory materials ?

- First, refractory materials can resist more than 1200 degrees, some of which are not insulation materials, such as firebricks, which can directly contact with heat source, has little insulation effect. Ceramic fiber, high silica, etc. are all refractory materials which can insulate. Second, insulation materials with poor performance usually is lower than 800 degrees, which have large thermal resistance, and low thermal conductivity, high porosity. Thus they reduce the thermal loss. To put it simply, insulation materials store most of the heat and only let a small part of heat lose through the air, thus the heat has been isolated. Glass fiber, rock wool, flexible material for thermal insulation, etc.

Send your message to us

97% FM Fused Magnesite Raw Materials for High Quality Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords