88% Rotary/Shaft/Round Kiln Alumina Calcined Bauxite Raw Materials for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

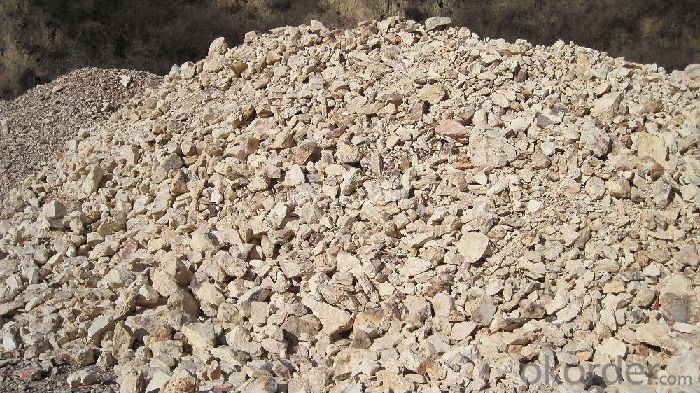

88% Rotary/ Shaft/ Round Kiln Alumina Calcined Bauxite Refractory Raw Material

Specifications

1. We directly supply calcined bauxite

2. Al2O3:70%/75%/80%/85%/86%/88%/90%

3. Size:0-1-3-5-8-10/200mesh/325mesh/400mesh/500mesh

Size:

Lumps /Grains:0-1mm,1-3mm,3-5mm,5-8mm /Powders:100mesh, 200mesh,325mesh

Product Description:

Bauxite, alumina or bauxite miner , main ingredients are aluminum oxide, hydrate alumina containing impurities,

is an earthy mineral.White or grey, brown yellow or light red by iron.From 4 to 3.9 g/cm3 density, hardness, 1 ~ 3, opaque, very brittle.

Very difficult to melt.Insoluble in water, soluble in sulfuric acid, sodium hydroxide solution.Mainly used for aluminium, refractory material.

Calcined Bauxite Grade:

Shaft Kiln Bauxite

Rotarty Kiln Bauxite

Round Kiln Bauxite

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: what grades are fire resistance of fireproofing glass divided into?

- Fire resistance of fireproofing glass is generally divided into three levels, class A glass can satisfy the requirements of fire resistance and thermal insulation at the same time. Class B, it's a kind of fireproofing glass that can satisfy the requirements of fire resistance and heat radiation strength at the same time. Class C can satisfy the requirements of refractory integrity, if you want to know more specific requirements, you can also surf the internet for a more detailed description.

- Q: How long does it take for refractory cement to solidify?

- 1. First you should be aware of the concepts of condensation and condesation time. Refractory cement belongs unshaped refractories, which when added water or liquid binding agent to mix, the agitation material will gradually lose thixotropy or plasticity and become in a state of solidification, thus is solidified. The time needed to finish the process is called solidification time. The whole process is divided into initial and final set. When beginning to lose plasticity called the initial setting, when called plasticity completely lost the final setting. 2. For refractory cement, the solidification time depends on the matching of the material and the parts and using methods. Under normal circumstances, in order to meet the requirements of time of construction, the initial set time should be no shorter than 40min, and the final set time should be no longer than 8H 3. There are also some exceptions. When refractory cement is used for spraying and injection operation together with other refractory castable, the set time is required as short as possible, sometimes flash set is required to prevent the occurrence of peeling or collapse of the spraying layer.

- Q: The effect of a high content of water in liquid resin exerted on refractory material?

- For one thing, Substandard whiteness, transportation, low quality and the storage of refractory material may account for this. For another, a high content of moisture reduced the performance of refractory material. A high content of moisture is equal to buy water with same money in terms of trade settlement. Based on this, we can’t consider the super-standard water content from a single aspect, because the water content in refractory material is definitely super-standard, and another problem is particle size. Many people hold the idea that excessive amount of water content may revive its original performance, but it tends to have influenced the quality of refractory material.

- Q: What refractories are accessible with ease in daily life?

- Basically there have all materials. But it depends on your needs.

- Q: What is required to do refractory material?

- But we can’t exclude that some products may contain a certain amount of metal materials: refractory material is non metallic materials whose physical and chemical properties make it suitable to be used under high temperature. Technically, it needs high purity raw material,high pressure molding, high temperature sintering to make refractory material. Refractory materials have two properties: first, the strong thermal shock resistance, second is slag resistance, the key is to look at what parts does it apply.

- Q: what should be paid sttention when buying the refractory?

- solve the resources and the cost as much as possible. Accurate understanding and knowing the material temperature changes of various partsin order to choose the appropriate refractories. 4: 3, work performance, for example, take measures to ensure the overall life, and it is a very good buying principles: melting in high temperature metal erosion. These are the four major problems to consider when using refractory. You can choose low prices and low transportation costs of materials to meet the basic principles under the conditions described above. 2.carefully observe the material to prevent the desturction and reducing the costs. according to the structure of furnace, reasonable coordination of all parts of the material, fully take the advantages of material characteristics and strive to develop the recycle, to avoid the destruction of the materials.1. the working characteristics and the sport condition and analyze the reason of destroying the material, which can not only gurantee the product quality and reduce the expenses, get familiar with the chemical component and physics of the material.

- Q: Development trend of refractory industry

- In the central provinces in Henan, Shanxi, Liaoning China main manufacturer of refractory material, which is the main origin of three China bauxite, magnesite and other refractory materials; refractories industry by the end of May 2009 more than 3236 enterprises; industry revenue reached 67 billion 52 million 540 thousand yuan, Henan Province, Liaoning, Shandong, Jiangsu, Hebei and other regions, and refractories industry in the development of better leading enterprises, such as blue and white, accessible, prco etc. at present, its sales in the industry in the proportion is still small, the largest sales is also inadequate in refractory industry in 4%. An enterprise should play a leading role in leading enterprises in the industry, and its turnover in the industry should be more than 15%. Obviously, at present the refractory industry in the leading enterprises do not have, and the refractory industry concentration needs to be improved, and the existing resources in the refractory industry integration, is undoubtedly the way this process effective and efficient.

- Q: What can red stone refractory do?

- Classification is divided into ordinary and special refractories two major categories. Ordinary refractories are divided into acidic, refractory, neutral and alkaline according to their chemical characteristics. According to the special refractory material consists of high temperature oxide, refractory compounds and high-temperature composite materials in addition, in accordance with the fire intensity can be divided into ordinary refractory products (1580 to 1770 DEG C), advanced refractory products (1770 to 2000 DEG C) and special refractory products (more than 2000 DEG C). According to the product shape can be divided into block (standard brick, special-shaped brick), special shape (crucible, sagger, pipes, etc.) (fibrous silicate aluminum, zirconium oxide and boron carbide material) and indefinite shape (refractory clay, pouring material and ramming material etc.). According to the sintering process, the products are divided into sintered products, casting products and fused blowing products. The main varieties of in general and special refractory materials, common varieties are mainly the following: acid refractories have a larger amount of silica brick and clay. Brick is siliceous products containing more than 93% SiO2, the use of raw materials with silica, silica and other waste. The silica acid slag erosion ability is strong, but vulnerable to the erosion of basic slag, its softening temperature is very high, close to the fire, the volume does not shrink after repeated burning, or even a slight swelling, but poor thermal shock resistance. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Containing 30% ~ 46% alumina clay brick, with refractory clay as the main raw material, refractory 1580 degrees to 1770 degrees, good thermal shock resistance, which belongs to the weak acid refractory material, resistance to acid slag, widely used, is the largest production of a kind of refractory material.

- Q: What is the mechanism of the errosion of the iron to the refractories?

- For example, the effect of the iron oxide: Mo corundum given temperature Fe2O3 solid solubility limit of the solid solution formed of corundum stone high solubility than the solid solution Mo Mo corundum lattice shape so Fe2O3Al2O3-SiO2-based material starts melting temperature of the system or the content of Al2O3 and Al2O3 / SiO2 ratio off Al2O3 / SiO2 & lt; 2.55 starting melting temperature of 1380 ℃ when Al2O3 / SiO2 & gt; 2.55 start melting temperature is increased 1460 ℃ and with its Al2O3 content increased gradually to increase the original atmosphere Fe2O3 original FeO off the solvent into the glass phase and the system starts melting temperature drops do not fall to 1240 ℃ 1380 ℃. Lower the melting point, increase the erosion, and reduce the life span.

- Q: Who knows about the types of Dalian thermal insulating and refractory materials?

- There are mainly following types: rock wool series, rubber and plastic series, glass wool series, mesh series, ventilation series, mortar series, extruded sheet series, geothermal series, insulation supporting pin series, glass silk cloth series. I hope my answer can help you.

Send your message to us

88% Rotary/Shaft/Round Kiln Alumina Calcined Bauxite Raw Materials for Refractory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords