Aslcoa Aluminum Coil 8011 Ho for Wine / Medicine PP Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of 8011 HO Aluminum Coil for Wine / Medicine PP Cap

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of 8011 HO Aluminum Coil for Wine / Medicine PP Cap

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of 8011 HO Aluminum Coil for Wine / Medicine PP Cap

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

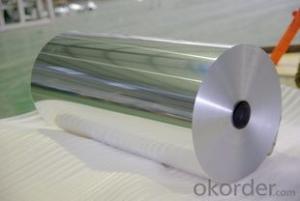

5. Image of 8011 HO Aluminum Coil for Wine / Medicine PP Cap

6. Package and shipping of 8011 HO Aluminum Coil for Wine / Medicine PP Cap

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different types of aluminum alloys used for making coils?

- Coils are made from various aluminum alloys that possess unique properties and characteristics, rendering them suitable for different applications. Some commonly utilized aluminum alloys for coils include: 1. Aluminum 1100: Renowned for its exceptional corrosion resistance, high thermal conductivity, and good formability, this alloy is frequently employed in scenarios necessitating high electrical conductivity, like transformers or electrical coils. 2. Aluminum 3003: Appreciated for its moderate strength and excellent workability, this alloy boasts good corrosion resistance and is often used in applications where formability and resistance to atmospheric corrosion are essential, such as condenser coils or evaporator coils in HVAC systems. 3. Aluminum 5052: Known for its high strength, excellent corrosion resistance, and good weldability, this alloy finds extensive use in situations demanding strength and resistance to saltwater corrosion, such as marine or offshore applications. 4. Aluminum 6061: Recognized for its high strength, good corrosion resistance, and excellent machinability, this alloy is commonly employed in applications requiring high strength and good weldability, such as heat exchanger coils or automotive cooling coils. 5. Aluminum 7075: Famed for its remarkable strength and excellent fatigue resistance, this alloy is often utilized in scenarios necessitating extreme strength and resistance to stress, such as aircraft or aerospace components. These are only a few examples of the diverse aluminum alloys employed in coil production. The specific alloy chosen depends on the application's requirements, including strength, corrosion resistance, formability, or electrical conductivity.

- Q: What role does the powdered aluminum play in this reaction?

- Aluminum is what burns or combines with oxygen. Learn How, you have it backwards. Iron oxide is the oxidizer.

- Q: Can aluminum coils be used for heat exchangers?

- Indeed, heat exchangers can make use of aluminum coils. Aluminum has gained popularity as a favored option for heat exchangers owing to its exceptional thermal conductivity, light weight, and resistance to corrosion. These coils usually find application in scenarios where heat transfer is necessary, such as HVAC systems, refrigeration units, and automotive radiators. Aluminum's high thermal conductivity enables efficient heat transfer, while its corrosion resistance guarantees durability and an extended lifespan for the heat exchanger. Moreover, aluminum coils can be effortlessly molded into different shapes and sizes, thereby showcasing their versatility for various heat exchanger designs.

- Q: How do aluminum coils contribute to sustainable manufacturing?

- Aluminum coils contribute to sustainable manufacturing by offering numerous environmental benefits. Firstly, aluminum is a highly recyclable material, meaning that the coils can be reused repeatedly without any degradation in quality. This reduces the need for virgin aluminum extraction, saving energy and resources. Additionally, the lightweight nature of aluminum coils reduces transportation costs and fuel consumption during shipping. Furthermore, aluminum is corrosion-resistant, leading to longer product lifespans and reducing the need for frequent replacements. Overall, the use of aluminum coils promotes sustainability through efficient resource utilization, reduced emissions, and increased product longevity.

- Q: What are the different types of surface treatments for corrosion resistance?

- Various materials can benefit from different surface treatments to enhance their resistance to corrosion. These treatments can be grouped into mechanical, chemical, and electrochemical methods. 1. To improve corrosion resistance, mechanical surface treatments involve physically altering or modifying the material's surface. Shot peening, sandblasting, and polishing are common methods. Shot peening induces compressive stresses by bombarding the material with small metal pellets, preventing corrosion. Sandblasting removes existing corrosion and creates a clean, smooth surface by blasting it with abrasive particles. Polishing, using abrasives, creates a smooth, reflective surface that reduces the chances of corrosion initiation. 2. Chemical surface treatments involve applying a chemical solution or coating to create a protective layer against corrosion. Chromating, for example, applies a chromate conversion coating that acts as a barrier against corrosion and improves adhesion for subsequent paint or coating layers. Anodizing, commonly used for aluminum surfaces, creates a thick oxide layer that enhances corrosion resistance and can provide decorative finishes. Other chemical treatments, like phosphating, passivation, and galvanizing, use specific chemical solutions or coatings to protect against corrosion. 3. Electrochemical surface treatments utilize electrochemistry principles to create a protective layer. Electroplating involves depositing a thin layer of a more corrosion-resistant material, such as zinc, nickel, or chromium, onto the base material's surface. Anodic protection connects a sacrificial anode to the material, causing the anode to corrode instead of the material itself. This method is commonly used for underground structures and pipelines. The choice of surface treatment for corrosion resistance depends on factors like the material, intended application, and desired level of protection. It is crucial to consider factors like cost, environmental impact, and performance requirements when selecting the appropriate treatment, as each method has its advantages and limitations.

- Q: Are aluminum coils resistant to chemical exposure?

- Aluminum coils are generally known to be highly resistant to chemical exposure. Aluminum itself has excellent corrosion resistance properties, making it suitable for various applications where it may come into contact with chemicals. The oxide layer that naturally forms on the surface of aluminum coils acts as a protective barrier, preventing further corrosion and degradation when exposed to many chemicals. However, it is essential to note that the resistance of aluminum coils to chemical exposure may vary depending on the specific type and concentration of the chemical involved. Some aggressive chemicals or strong acids may still cause damage or corrosion over time. Therefore, it is always advisable to consult with experts or refer to specific chemical compatibility charts to determine the compatibility of aluminum coils with particular chemicals or environments.

- Q: what is the final temperature of 250g of water whose initial Temperature is 25 C if 80-g of aluminum initially at 70 C is dropped into the water? The specific heat of aluminum is 0.215 cal/C g how do you do it? our teacher did not show us how and it is not in the book

- Given Data :-- Mass : Aluminium m(a) = 80 g, Water m(w) = 250 g Initial Temperature : Aluminium t? = 70 C and Water t?' = 25 C Final Temperature of both ( aluminium and water ) = T C (assume) Since Aluminium is initially at a temperature higher than that of water, it (aluminium) will lose heat to water . Heat lost by Al = Q = mass of Aluminium x sp.heat capacity of Aluminium x Temp. change = Q = 80 x 0.215 x ( 70 - T ) cal Heat gained by water = Q' = mass of water x sp.heat capacity of water x Temp. change = Q' = 250 x 1 x ( T - 25 ) According to principle of calorimetery . = Heat lost by aluminium = heat gained by water. = 250 x 1 x ( T - 25 ) = 80 x 0.215 x ( 70 - T ) = T = 27.9 C .... ( Rounded to one decimal place )...... Answer Answer .

- Q: Are there any safety considerations when handling aluminum coils?

- Yes, there are safety considerations when handling aluminum coils. Aluminum coils can be sharp and have the potential to cause cuts or punctures if not handled carefully. Additionally, aluminum dust or fumes generated during handling or cutting processes can pose health hazards if inhaled. It is important to wear appropriate personal protective equipment, such as gloves and safety glasses, and to work in a well-ventilated area to minimize the risk of injury or exposure to harmful substances.

- Q: A cube of solid aluminum has a volume of 1.00 m3 at 20°C. What temperature change is required to produce a 130 cm3 increase in the volume of the cube?

- The linear expansivity of aluminum is 23 x10^-6 /K. Bulk expansivity is 3 x 23 x10^-6 / k For 130 [cm^3] the temperature required is 130 [cm] ^3/ 3 x 23 x10^-6 = 0.00013/[3 x 23 x10^-6] = 1.88 K ========================= If each side of the cube of side 1m expands by e, then its new volume = [1+e]^3 = 1 + 3e + 3e^2 +e^3. Neglecting high powers of e as negligible, the increase in volume is 3e. But e = 23 x10^-6 x rise in temperature 3e = 3*23 x10^-6 x rise in temperature. Given 3e = 0.00013 0.00013= 3*23 x10^-6 x rise in temperature Rise in temperature = 0.00013 / 3*23 x10^-6 = 1.88 K

- Q: I have heard that aluminum may be a contributing agent in causing Alzheimer's disease, and that if we drink from aluminum cans, that we get aluminum into our system from them. It seems like this would be pretty easy to test in a laboratory, whether or not there are aluminum particles in the contained beverage. But I have heard or read that the inside of the cans are coated with something. So is this just typical uninformed rumors from the Internets, or is there anything to it? Hate to sound rude, but I am not really interested in opinions, like Well I don't think they would sell them if... or Oh yes, I think you get lots of aluminum from it. I am only interested in facts, not gut feelings or opinions.

- It's a fact that the cola industry controls us through microchips floating in their drinks

Send your message to us

Aslcoa Aluminum Coil 8011 Ho for Wine / Medicine PP Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords