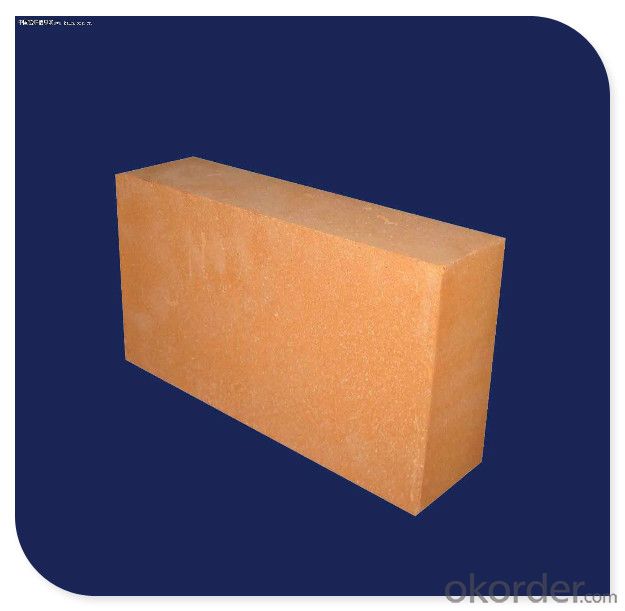

75% -80% AL2O3 for Steel Ladle Linings High Alumina refractory brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

75% -80% AL2O3 for Steel Ladle Linings High Alumina refractory brick

1.Description

High Alumina Bricks for Steel Ladle Linings

AL2O3:55-80%

ISO9001-2008

HIGH ALUMINA BRICKS FOR STEEL LADLE LININGS | ||||||

Goods Brand | CL-55 | CL-65 | CL-75 | CL-80 | PZCL-78 | |

Al2O3(%) min | 55 | 65 | 75 | 80 | 78 | |

Refractriness under load 0.2 Mpa ( °C) min | 1470 | 1490 | 1510 | 1530 | 1550 | |

Apparent porosity (%) max | 22 | 28 | 28 | 24 | 21 | |

Cold Crushing strength (MPa)min | 45 | 35 | 40 | 50 | 70 | |

Shrinkage after reheating (%) max | 1450°Cx2h | 0.1~0.5 | *** | *** | *** | *** |

1500°Cx2h | *** | 0.1~0.5 | 0.1~0.5 | *** | *** | |

1550°Cx2h | *** | *** | *** | 0.1~0.5 | 0.4~0.3 | |

Feature:

1.High compression strength.

2.Top high-temperature capability.

3.Excellent thermal stability.

4.Low thermal conductivity.

5.Powerful penetrating-proof capability.

6.Good erosion-resistance.

7.Long service life.

Application:

Refracory brick plant can be in direct contact with the flame,this insulating brick can be used as linings or as thermal preservation layers in various industrial furnaces and kilns in metallurgical industry, ceramic industry, chemical industry, machinery industry.

such as blast furnace, hot blast stoves ,electric arc furnace, cement kiln,melting furnace, ignition furnace, flue, refining equipment, heating equipment and piping, regeneration device, gas furnace, soaking furnace, annealing furnace, heat reaction chamber and other thermal industrial equipment.

FAQ

1. Do you provide samples?

Yes, samples are free. Guarantee samples quality same as mass production quality.

2. What's the MOQ of trial order?

No limit,We can offer the best suggestions and solutions according to your condition.

3. Can we visit your company?

Of course,welcome at any time,seeing is believing.

4. Do you accept OEM?

Yes, we can do OEM.

5. What are the payment terms?

Usually T/T, D/A, D/P, L/C, Western Union ,others could be discussed .

6. How long is delivery time?

The delivery time will be determined according to the quantity of the order.

7. How are your products’ quality?

More than 20 years of production experience. The products will be strictly inspected before shipment, so the quality could be guaranteed.

8. How to slove the quality problems?

If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

9. What is the service life of your bricks?

The service life of different bricks is unlike.It also depends on your using condition and method.

10. How about your company's certification?

ISO9001 and Test Report,also we could apply other necessary certification.

11. How about your price?

Quality will be guaranteed. Competitive prices based on same quality.

Our services:

1.Adhering to the business philosophy "Mutual Trust, Mutual Benefit, Mutual Profit, Faith Oriented".

2.According to your requirements to produce your order and OEM/ODM service is available.

3.Products are inspected through SGS and BV etc and accord with the international standard.

4.Your inquiry related to our products or prices will be replied in a timely manner.

- Q: What are the high aluminum bricks made of?

- The amount of refractory mud accounts for about 6% of the brick weight

- Q: What are the main components of high alumina bricks?

- High alumina brick materials according to the main mineral phase can be divided into: aluminum silicate minerals, such as sillimanite, kyanite, andalusite, and synthetic mullite.

- Q: Introduction of high alumina brick

- Made from alumina or other raw materials of high alumina content; formed and calcined. High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining.

- Q: What is the price of the latest thermal insulation material?

- There are many kinds of insulation materials, and the price will fluctuate with the market. Small quantities of inquiry or procurement, then go directly to the local thermal insulation market, a wide variety of prices are basically the market price.

- Q: Density of high alumina bricks

- Alumina content of 48% or more, mainly from mullite and glass phase or corundum composition of lightweight refractory. The volume density is 0.4 ~ 1.35g/cm3. The porosity is 66% ~ 73%, and the compressive strength is 1 ~ 8MPa. Better thermal shock resistance.

- Q: The cloth blowing is not uniform on the lime kiln refractory brick is damaged it

- Lining 1 yuan to prevent direct damage to the Sindh kiln high temperature flame or air, to protect the kiln carcass; 2, to prevent harmful substances (CO, SO2) erosion of the kiln body; 3, to prevent corrosion, material flow on the kiln body; 4, reduce the kiln temperature, kiln body to prevent oxidation 5, has the function of corrosion; thermal insulation; 6, to improve the coating performance.

- Q: What is the density of a super high alumina brick and what is the price?

- Of course, the transaction price, please choose refractory brick manufacturer is better.

- Q: What materials are used for roof insulation?

- The other one is inorganic insulation materials, such as Portland, rare earth insulation, the thickness should be 5 cm or more, up to the high cost of auxiliary materials of construction, to reinforce, new inorganic insulation material, the material thickness, on the line of 2-3 cm, direct smear on the top of the house, without auxiliary material, than the price of wool, high aluminum silicate cotton.

- Q: Use of high alumina refractory bricks?

- Because of the high Al2O3 high aluminum products, low impurity content, the formation of fusible vitreous body less so than the clay brick high load softening temperature, but because mullite crystallization has not formed the network organization, so the load softening temperature is not high silica brick.

- Q: What is the high temperature limit of refractory bricks and refractory soil?

- According to the preparation process can be divided into bricks, brick, electric melting brick (Rong Zhuzhuan), the refractory insulating bricks; according to the shape and size can be divided into standard brick, ordinary brick, specific rotation. It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature.

Send your message to us

75% -80% AL2O3 for Steel Ladle Linings High Alumina refractory brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords