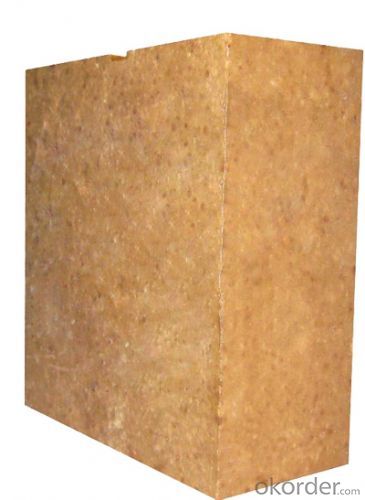

High Alumina Brick - 75%-80% Al2O3 for Steel Ladle Linings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 800000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shanxi, China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 0 | Al2O3 Content (%): | 55-80 | MgO Content (%): | 0 |

| CaO Content (%): | 0 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0 |

| SiC Content (%): | 0 | Model Number: | CL-55 CL65 CL75 CL80 | Brand Name: | CNBM |

| AL2O3: | 55-80% |

Packaging & Delivery

| Packaging Details: | ABOUT 1MT WOODEN PALLET |

| Delivery Detail: | WITHIN 45DAYS |

Specifications

High Alumina Bricks for Steel Ladle Linings

AL2O3:55-80%

ISO9001-2008

HIGH ALUMINA BRICKS FOR STEEL LADLE LININGS | ||||||

Goods Brand | CL-55 | CL-65 | CL-75 | CL-80 | PZCL-78 | |

Al2O3(%) min | 55 | 65 | 75 | 80 | 78 | |

Refractriness under load 0.2 Mpa ( °C) min | 1470 | 1490 | 1510 | 1530 | 1550 | |

Apparent porosity (%) max | 22 | 28 | 28 | 24 | 21 | |

Cold Crushing strength (MPa)min | 45 | 35 | 40 | 50 | 70 | |

Shrinkage after reheating (%) max | 1450°Cx2h | 0.1~0.5 | *** | *** | *** | *** |

1500°Cx2h | *** | 0.1~0.5 | 0.1~0.5 | *** | *** | |

1550°Cx2h | *** | *** | *** | 0.1~0.5 | 0.4~0.3 | |

Our Service:

1. Your inquiry related to our products or prices will be replied in 24hours.

2. Manufacturer with large capacity, ensure the fast production cycle after confirmed the order.

3. Our professional technicians will answer your entire enquiry in patient.

4. To meet the refractory solutions, we can serve as your instructions.

5. Protection of sales area and private information for our entire customer.

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- In the course of the production of lime kiln, the local block of refractory brick is a very dangerous signal. It is suggested that you stop the kiln to prevent the collapse of a large area. Lime kiln is the main equipment for the production of limestone kiln and rotary kiln is two, with the growth of calcium carbide lime kiln industry, iron and steel industry, the construction industry to the amount of limestone has become the main production equipment, and refractory bricks became the heart of lime kiln.

- Q: What are the specific raw materials for plastic pallets?

- There are two kinds of raw materials for plastic pallets: one is polypropylene (PP) and the other is polyethylene (HDPE).Plastic pallets for logistics storage: pp+pe material, recycled material 10%;Plastic trays for food trays: food grade PP, PE, pc;Polyethylene (HDPE) has excellent impact resistance and cold resistance, and it can resist environmental stress cracking. Excellent chemical stability, good oil resistance. Water absorption and tiny, low permeability, organic vapor transmission rate is larger. Electrical insulation is good, in all frequency range, dielectric properties are extremely excellent.

- Q: What are the common thermal insulation materials for thermal conductivity?

- Aerogels are known to be the lightest solid materials in the world. It is made of nanometer silica aerogel as main material and is compounded by special process. The utility model has the advantages of high temperature resistance, low thermal conductivity, small density, high strength, green environment protection, waterproof and non inflammable performance. At the same time, with excellent sound insulation and shock absorption performance, it is now widely used in metallurgy, chemical, national defense, aerospace and other fields, is an indispensable high-performance insulation materials.

- Q: How to reduce porosity of high alumina brick

- In order to reduce the porosity of high alumina brick, the corresponding measures should be taken from the selection of raw materials, batching, mixing, molding and firing.The water absorption rate of the first grade high alumina bauxite clinker should be less than 5%, and the water absorption rate of two grade high alumina material should be less than 7%. Fine grinding of soft clay and bauxite clinker with less than 4% water content. Mixed fine milling ingredients with this, can reduce the porosity of bricks.

- Q: What are the high temperature refractory mortars made of?

- Siliceous mud, mineral composition and chemical composition is similar with silica, excellent corrosion resistance, water glass slurry, drying shrinkage, but also can be used for bonding fiber products, sealing furnace wall.

- Q: What are the requirements for refractory materials in heat treatment furnace?

- Fire resistance is an important performance index of refractory materials, but it does not represent the highest temperature in actual use of refractory materials. In actual use, refractories also bear certain pressure, therefore, must consider the high strength at high temperature refractory material, which is in high temperature under certain pressure without deformation, such as the NZ-40 refractory refractory degree up to 1730 DEG C, but the maximum temperature is only 1350 degrees celsius.

- Q: The difference between light high alumina brick and heavy aluminum brick

- High aluminum brick is one of the ideal heat insulating material, with high strength, low thermal conductivity, good insulation performance, low price and other characteristics, has been widely used in ceramic tunnel kiln, roller kiln, shuttle kiln, kiln wall, it is also used in various heating furnace coking furnace of iron and steel industry and other thermal equipment heat treatment, lining material, and has broad market prospects.

- Q: What is the apparent porosity of high alumina brick?

- In the production of high alumina bricks in addition to the entity, there are many different sizes and shapes of different pores, pores can be divided into three categories: one side closed the other side and the outside world is called open pores, closed in the product not communicated with the outside is called closed pores, penetrating through pores called the few products.

- Q: What kind of material is the general metal case?

- We usually discuss the electromagnetic radiation of computer enclosures, mainly RF radiation, followed by MF leakage.Switch signal of RF radiation from computer high-speed leakage, such as one of the energy radiation is CPU frequency, graphics, display output line, keyboard, is the source of the operating characteristics of the computer leaked out, is also the main part of computer security.For the absorption of radio frequency radiation, the best is the use of copper materials, the use of other metals can also, thickness enough on the line.The most vulgar description is that people can sit in the case is a good thing.

- Q: What are the categories of bricks?

- Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

Send your message to us

High Alumina Brick - 75%-80% Al2O3 for Steel Ladle Linings

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 800000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords