7075 PE/PVDF Coated Aluminum Coils Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PE/PVDF Coated Aluminum Coil Mill Finish

l Product Introduction

Coated aluminum coils are widely applied to aluminum ceiling, roofing, fireproof roller shutter, doors, wall panel, facade cladding, etc.

l Product Specification:

| PE/PVDF coated aluminum coil | material 1060/3003/3004/3105 |

| painting Thickness | Single-coated ( 4-20 microns ); double-coated ( 25-28 micron ); 3 -coated ( 35-38 micron ) |

| width | within 1660mm |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advanced payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Color coated aluminium coil is one of the popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality color coated aluminium coil to the world.

l CNBM World Wide

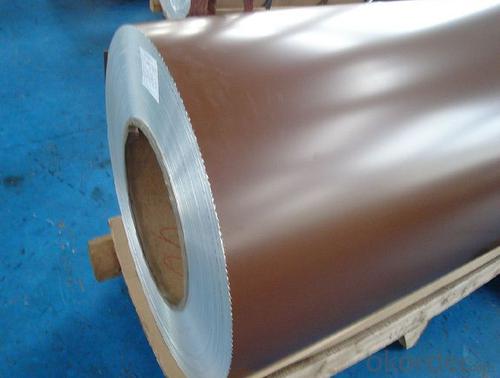

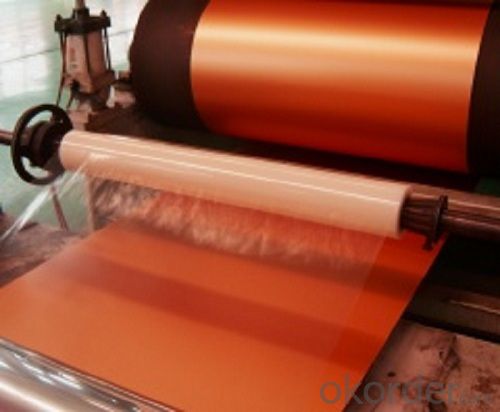

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What are the best rust-proof coils? Please tell me the model and manufacturer in Shangdong. Thank you.

- 3003 aluminum coil, AL-Mn series alloy, is the most widely used rust-proof aluminum with the density being 2.73. It is applicable to insulation projects such as pipe insulation, packaging, machine parts, refrigerator, air conditioning and ventilation pipes and other wet environment.

- Q: What are the different types of aluminum coils available?

- There are several different types of aluminum coils available in the market. Each type is designed to cater to specific requirements and applications. 1. Mill Finish Aluminum Coils: These coils have a plain, shiny surface with no additional treatments or finishes applied. They are often used in general applications where aesthetics are not a major concern. 2. Anodized Aluminum Coils: Anodizing is an electrochemical process that forms a protective layer on the surface of the aluminum. This type of coil is highly corrosion-resistant and provides excellent durability. Anodized aluminum coils are commonly used in architectural applications, such as building facades, window frames, and signage. 3. Painted Aluminum Coils: These coils are coated with a layer of paint, typically through a coil coating process. The paint provides not only aesthetic appeal but also protection against weathering, UV radiation, and corrosion. Painted aluminum coils are widely used in the construction industry, for roofing, cladding, and rainwater goods. 4. Embossed Aluminum Coils: These coils have a textured or patterned surface created by embossing rollers. The embossed patterns can vary from simple designs to intricate motifs, providing both aesthetic appeal and enhanced slip resistance. Embossed aluminum coils are commonly used in flooring, decorative panels, and transportation applications. 5. Pre-painted Aluminum Coils: Similar to painted coils, pre-painted aluminum coils are coated with paint. However, the coating is applied before the coil is formed, allowing for greater flexibility in terms of color options and finishes. Pre-painted aluminum coils find applications in various industries, including automotive, appliance manufacturing, and signage. 6. Clad Aluminum Coils: Clad aluminum coils consist of two layers of aluminum bonded together, usually through a rolling or extrusion process. The purpose of the clad is to combine the desirable properties of different aluminum alloys, such as strength, corrosion resistance, or conductivity. Clad aluminum coils are commonly used in the automotive, aerospace, and electrical industries. In addition to these types, there are also specialized aluminum coils available for specific applications, such as heat exchangers, condenser coils, and transformer windings. These coils are designed with specific properties and characteristics to meet the requirements of these specialized applications.

- Q: who invented aluminum and or aluminum foil?

- placed extremely oil or butter on a paper napkin or paper towel and rub on the pan. do not forget the ends, it truly is the position pies especially stick. No, it truly is not had to oil an aluminum pan, in spite of the undeniable fact that the perimeters do look to adhere.

- Q: Are aluminum coils suitable for outdoor signage?

- Yes, aluminum coils are suitable for outdoor signage. Aluminum is a durable and weather-resistant material that can withstand various outdoor elements, such as rain, sunlight, and temperature changes. It is also lightweight, which makes it easier to install and transport. Additionally, aluminum coils can be easily shaped and formed into different designs, allowing for versatile and eye-catching signage options.

- Q: This question asks whether aluminum coils are produced using recycled materials.

- <p>Yes, aluminum coils can be made from recycled materials. Recycling aluminum is a common practice because it conserves resources and energy. Recycled aluminum, also known as secondary aluminum, is processed from various waste materials such as used beverage cans, automotive parts, and construction materials. The recycling process involves melting the scrap aluminum, which requires significantly less energy compared to producing aluminum from raw materials. This makes the production of aluminum coils from recycled materials more sustainable and environmentally friendly.</p>

- Q: This question asks for an explanation of the various materials used for coating aluminum coils.

- <p>Aluminum coil coating materials can be categorized into several types, including: 1. Organic coatings, such as polyester, acrylic, and polyvinylidene fluoride (PVDF), which offer good weather resistance and color stability. 2. Inorganic coatings, like fluoropolymers, which provide exceptional chemical resistance and high-temperature stability. 3. Metal coatings, such as zinc or other metals, used for enhanced corrosion resistance. 4. Ceramic coatings, which are known for their high durability and resistance to heat and chemicals. 5. Laminates, which combine multiple materials for specific performance characteristics. These coatings are chosen based on the intended application of the aluminum coil, such as in construction, automotive, or packaging industries.</p>

- Q: How do aluminum coils contribute to sustainable building practices?

- Several ways exist in which aluminum coils contribute to sustainable building practices. To begin with, aluminum, being a highly recyclable material, has a minimal impact on the environment in terms of production and usage of aluminum coils. The process of recycling aluminum requires significantly less energy compared to the production of new aluminum, thereby reducing greenhouse gas emissions and conserving natural resources. Furthermore, aluminum coils possess the qualities of being lightweight and durable, making them an excellent choice for sustainable building practices. The lightweight nature of aluminum reduces the burden on the building structure, resulting in lower transportation costs and energy consumption during construction. Moreover, the durability of aluminum coils ensures a long lifespan, reducing the need for frequent replacements and the generation of associated waste. Additionally, aluminum's resistance to corrosion and minimal maintenance requirements contribute to the longevity of buildings, thereby reducing the need for repairs and replacements over time. This not only saves resources but also diminishes the overall environmental impact of the building. Moreover, aluminum coils exhibit excellent thermal conductivity, which can enhance energy efficiency in buildings. When incorporated into insulation systems or HVAC systems, aluminum coils assist in temperature regulation and minimize energy consumption. Consequently, this can lead to reduced energy bills and a smaller carbon footprint for the building. Lastly, aluminum coils find utility in various applications, including roofing, cladding, and ventilation systems. Their versatility allows for innovative and creative design solutions, supporting sustainable building practices by integrating energy-efficient features and promoting natural ventilation. In conclusion, aluminum coils contribute to sustainable building practices through their recyclability, lightweight and durable nature, resistance to corrosion, thermal conductivity, and versatility. By opting for aluminum coils in construction, we can reduce the environmental impact of buildings, conserve resources, and promote energy efficiency, ultimately fostering a more sustainable built environment.

- Q: Can aluminum coils be used in automotive manufacturing?

- Yes, aluminum coils can be used in automotive manufacturing. Aluminum is a lightweight and versatile material that offers various advantages in the automotive industry. It is commonly used to make parts like body panels, engine blocks, wheels, and heat exchangers. The use of aluminum coils in automotive manufacturing allows for improved fuel efficiency, as the reduced weight of the vehicle contributes to lower energy consumption. Additionally, aluminum has excellent corrosion resistance, making it suitable for use in various weather conditions. Overall, the use of aluminum coils in automotive manufacturing provides numerous benefits, making it a popular choice for many car manufacturers.

- Q: Are aluminum coils suitable for thermal insulation?

- Aluminum coils, unfortunately, do not serve as suitable thermal insulation. With its high conductivity, aluminum promptly transfers heat, rendering it ineffective in impeding heat transfer between areas or maintaining desired temperatures within a given space. In order to achieve optimal thermal insulation, materials boasting low thermal conductivity, such as fiberglass, mineral wool, or foam insulation, are preferred as they effectively minimize heat transfer and offer superior insulation.

- Q: What type of equipment is used to process aluminum coils?

- The type of equipment commonly used to process aluminum coils includes slitters, cut-to-length lines, roll formers, and annealing furnaces.

Send your message to us

7075 PE/PVDF Coated Aluminum Coils Mill Finish

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords