Stainless Steel Wire Mesh For Screen Printing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

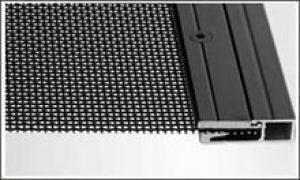

Material: SUS/AISI 201 202 302 304 304HC 304L 316 316L etc.

Characteristic & Use: Excellent resistance against acid, alkali, heat and corrosion, extensively used in processing of oil, chemical, food, making wire mesh filter, also sorting and screening of solid, liquid and gas in mine, metallurgy, airspace and machine making etc.

More Information

1) product range : 30m ( up to 200m) long and in width of 36’ 48’ 1m 1.2m 1.5m 2.0m etc. or cut to length panels as per client’s requirement.

2) Weave: Plain Weave, Twill Weave ; Plain Dutch Weave, Dutch Twill Weave.

3) Mesh counts: 1 mesh to 635 mesh.

Quality: Meet Australia Market.

Mesh per inch: 11mesh x 11mesh

Wire Diameter: 0.8mm

Surface treatment: Black powder coated,Gray powder coated

Stainless steel security screens Property:

1. Equal tensile stainless steel wire,Equal wire diameter.

2. Equal hole size

3. Flat and straight surface

4. Meet australia standard,Pass knife test,Impact test,Jemmy attack test

1.6mm dia Stainless Steel Security Window Screen Mesh

Material:Stainless steel 304, 316, carbon steel.

Wire diameter and mesh size:

0.7mm x 12 mesh,

0.8mm x 11 mesh (Common specification),

0.9mm x 10 mesh,

1.0mm x 8.5 mesh,

1.6mm x 4 mesh.

Weaving method:Plain weave, crimp weave.

Surface: Electrostatic spray. The common colors are black, gray, white, yellow, etc.

1.Features:Acid resistant,Alkali resistivity,High-tempreture Resistance,Abrasion Resistant,Long Life,ect.

2.Application:It is widely used in these industries ,such as petroleum,chemical,chemical fiber,tyres manufacturing ,metallurgy,medicine,food.With its excellent resistance against acid,alkali and heat,find extensive uses in filtering , and sorting of solid ,liquid and gas

3.Stainless Steel Wire Mesh:can be divided into Stainless Steel Wire Mesh Square Opening and Stainless Steel Wire Mesh Dutch Weave according to weaving types, while Square Opening Stainless Steel Wire Mesh can be further divided into square wire mesh plain weave and square wire mesh twill weave.

FAQ

Advantages we have

A.Skilled and experienced workers

B.Perfect processing capabilities including shearing, sawing, punching, drilling, welding and additional fabrication

expertise

C.Better engineering, tighter tolerances, better prices, shorter lead times

D.Better value, quicker turnarounds, flexibility in options.

Benifits you get

A.Stable quality:Coming from good material,skilled workers and technique.

B.Lower Price:Not cheapest but the lowest at the same quality.

C.Good Service:Satisfactory service before and after sale.

D.Delivery Time:30-45 days for mass production

- Q: Barbed wire mesh 20 mesh and 30 mesh what is the difference

- The sparseness of the network is different, in general, the larger the mesh, the closer the mesh is. The smaller the mesh, the thinner the cell.

- Q: Wall tiles how to hang iron wire mesh

- Fenqian wire mesh for the cold galvanized welded wire mesh, is the choice of high-quality low-carbon steel wire welding wire, the intersection of advanced welding technology were vertical and horizontal welding, and then cold plating;

- Q: Construction in the wall and the beam at the junction of nail wire mesh what role

- Fixed pipe: the appearance of the insulation layer laying wire mesh with nylon tie to fix the pipe, characterized by fast construction, accurate positioning, the role of all the pipe device is good.

- Q: How does proe draw wire mesh?

- With a way to scan it to a roughness (wire diameter), because the barbed wire is two cross, so the mirror in the center of a mirror out of the two wire will be created into a group, (selected - right - group )

- Q: What is the barbed wire in the cable line?

- If there is no such network, the TV signal is highly susceptible to some of the frequency of interference, resulting in increased noise on the screen, and even lead to poor synchronization.

- Q: What is the barbed wire fence? What is the general specification?

- With a variety of different columns to connect. Constitute a nice, high protective performance of the barbed wire fence.

- Q: Why is the effect of electromagnetic radiation shielding with wire mesh?

- Living environment rarely have high-frequency equipment, so the high frequency magnetic field component is very small, 0.5 has been very small, unless the professional equipment is difficult to distinguish, so the change can not be measured.

- Q: Is the warm tube laid on top of the steel wire or below?

- and that the road is broken, then the loop must be replaced by all the warm pipe, which means that your room layout of the road to warm all the area to all Out of all to replace the new pipe to replace.

- Q: Barbed wire fence is what the iron ring

- The wire rod is twisted by a fully automated barbed wire machine. Folk commonly known as Tribulus terrestris, barbed wire, thorn line. Type: single wire twist and double wire twist. Raw materials: high quality low carbon steel wire.

- Q: How is the wire mesh made

- materials used generally use high-quality low-carbon steel or stainless steel. In general, it is necessary to produce a number of processes such as plate peeling, pickling, washing,

Send your message to us

Stainless Steel Wire Mesh For Screen Printing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords